Wiha fibre-glass-reinforced callipers – Wiha Tools Measurement tools _ articulated hose systems User Manual

Page 5

2

1

1

2

296

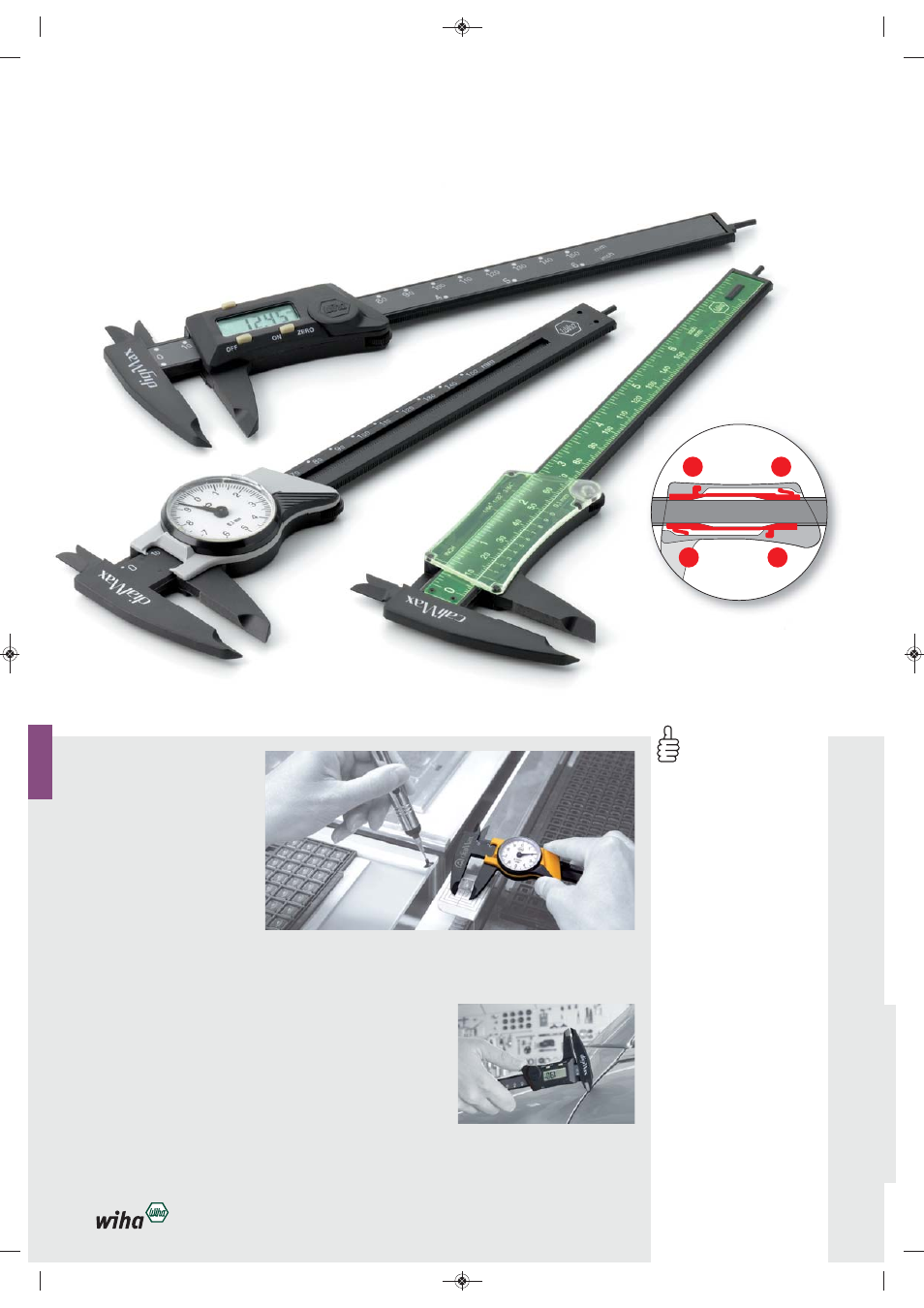

Wiha fibre-glass-reinforced callipers.

Precision made in Switzerland.

The dialMax ESD calliper can be used for

measuring delicate electronic components.

The measuring jaw of the fibre-glass

reinforced calliper enables scratch-free

measurement of even very delicate,

shiny surfaces.

The Wiha callipers from the "max"

range are manufactured since 1965

with Swiss precision. Due to the

unique advantages made available

by the non-metal, high-tech material

with 50% fibre-glass component,

the callipers have found new appli-

cations where their advantages are

distinct when compared to the more

heavy metal designs.

They are particularly suitable for

measuring high-quality and highly

sensitive objects.

These measuring tools are also

ideal for all metal, wood and plas-

tic-

processing applications, for field

staff and service engineers.

Thanks to their antimagnetic

properties, Wiha callipers prevent

measuring surfaces from becoming

soiled by metal filings, which could

impair the accuracy of measure-

ments. Since they are made of non-

Wiha fibre-glass-

reinforced callipers.

Permanent

– very rigid with 50% fibre-glass

component

High tech material

– non-metallic

– non-corrosive

– non-magnetic

– minimum thermal conductivity

– electrically insulating

– resistant to chemicals

– temperature resistant

measuring surfaces:

temporarily to 180°,

permanently at 100-120°

Versatile applications

– highly sensitive measurement

objects

– electronic components

– sensitive surfaces

– model making and prototype

production

– food industry

– ESD protective zones

Precise

– practical ratchet guarantees

equally balanced clamping

force of the measurement jaws

corrosive material, Wiha callipers

can also be used in damp working

environments.

With the Wiha dialMax ESD callipers,

measuring at ESD workstations

and in ESD protection zones is now

possible for the first time.

Play free motion of the sliding compo-

nents components through precision de-

sign for precise measurement results:

1. Fixed position

2. Flexible spring component

EN_s294-298_Messw_2012 14.02.12 19:36 Seite 296