Herman Miller Eames Tandem Sling Seating - Environmental Product Summary User Manual

Eames, Tandem sling seating

Our sustainability goals by the year 2020:

• Zero carbon footprint

• Zero landfill

• Zero hazardous waste generation

• Zero air emissions (VOCs)

• Zero process water use

• 100 percent renewable electrical energy use via renewable

energy credits and a power purchase agreement

• Company buildings constructed to a minimum

LEED Silver certification

• 100 percent of sales from DfE approved products

Environmental Product Summary

Eames

®

Tandem Sling Seating

Design Story: A Time-Tested Traveler’s Friend

Charles and Ray Eames originally designed their

tandem sling seating in 1962 for Chicago’s O’Hare

International Airport. They based the design on the

sling system developed for their Aluminum Group chairs.

Today, more than 40 years later, tandem sling seating

still reliably serves millions of O’Hare visitors and other

travelers passing through public transportation stations

worldwide. Its sleek, contemporary design never goes

out of style, and weary travelers find its wide, padded

seats a comfortable, inviting place to rest.

Terminal operators are equally pleased with its

flexibility, durability, and easy maintenance. And

today’s Eames tandem sling seating incorporates

recycled—and recyclable—materials for a more

environmentally friendly product.

Herman Miller’s Design Protocol

Our commitment to corporate sustainability naturally

includes minimizing the environmental impact of each

of our products. Our Design for Environment team (DfE)

applies environmentally sensitive design standards to

both new and existing Herman Miller products.

Our DfE Protocol goes beyond regulatory compliance to

thoroughly evaluate new product designs in four key

areas:

• Material Chemistry and Safety of Inputs—

What chemicals are in the materials we specify, and

are they the safest available?

• Disassembly—Can we take products apart at the

end of their useful life, to recycle their materials?

• Recyclability—Do the materials contain recycled

content, and more importantly, can the materials be

recycled at the end of the product’s useful life?

• LCA—Have we optimized the product based on the

entire life cycle?

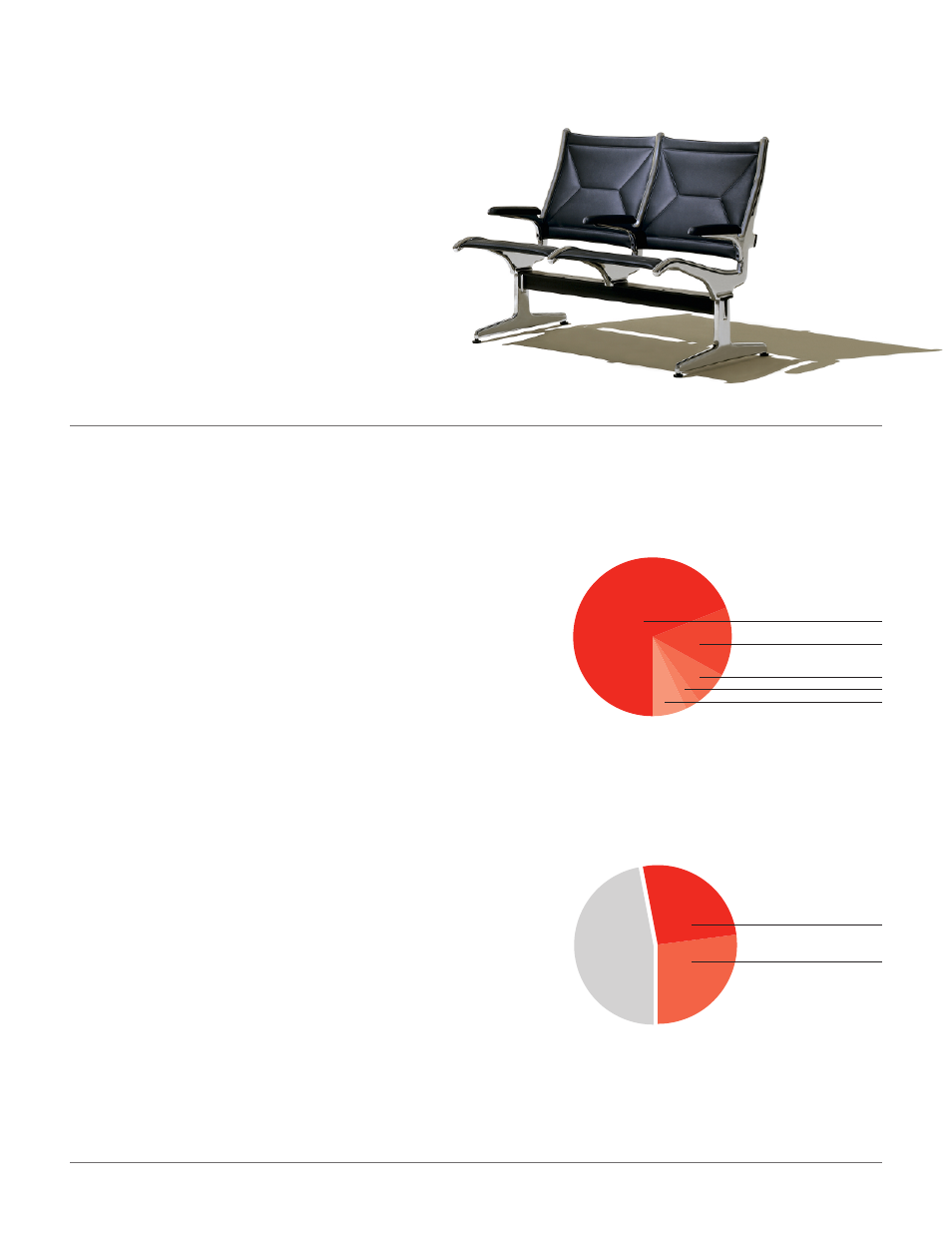

Material Content

Eames tandem sling seating’s components are

constructed from aluminum, steel, textile, foam, other

material.

Eames tandem sling seating is up to

95 percent

recyclable at the end of its useful life.

This seating is comprised of

53-percent recycled

materials. This figure breaks down to 27-percent

post-consumer and 26-percent pre-consumer recycled

content.

• Die-cast aluminum components are typically made

from more than 95-percent recycled material and

are 100 percent recyclable.

• Steel components contain approximately 35 percent

recycled content and are 100 percent recyclable.

z

1

Y

® Y and Z and Eames are among the registered trademarks of Herman Miller, Inc.

® GREENGUARD is a registered trademark of the GREENGUARD Environmental Institute.

© 2012 Herman Miller, Inc., Zeeland, Michigan

ALUMINUM 69%

STEEL 14%

TEXTILE

7%

FOAM

3%

OTHER

7%

PRE-CONSUMER

RECYCLED CONTENT 26%

POST-CONSUMER

RECYCLED CONTENT 27%