Bosch PCM 7 User Manual

Page 31

English | 31

Bosch Power Tools

1 609 929 U75 | (19.7.10)

Working Advice

General Sawing Instructions

f

For all cuts, it must first be ensured that the

saw blade at no time can come in contact

with the fence, screw clamps or other ma-

chine parts. Remove possibly mounted aux-

iliary stops or adjust them accordingly.

Protect the saw blade against impact and shock.

Do not subject the saw blade to lateral pressure.

Do not saw warped/bent workpieces. The work-

piece must always have a straight edge to face

against the fence.

Long workpieces must be underlaid or support-

ed at their free end.

Marking the Cutting Line (see figure J)

A laser beam indicates the cutting line of the

saw blade. This allows for exact positioning of

the workpiece for sawing, without having to

open the retracting blade guard.

– For this, switch the laser beam on with the

switch 20.

– Align the cutting mark on your workpiece

with reference to the right-hand edge of the

laser line.

Position of the Operator (see figure K)

f

Do not stand in a line with the saw blade in

front of the machine. Always stand aside of

the saw blade. This protects your body

against possible kickback.

– Keep hands, fingers and arms away from the

rotating saw blade.

– Do not cross your arms when operating the

tool arm.

Permissible Workpiece Dimensions

Maximal workpiece sizes:

Minimal workpiece sizes

(= all workpieces that can be clamped left or

right from the saw blade with the supplied ma-

terial clamp 14): 100 x 40 mm (length x width)

Cutting capacity, max. (0°/0°): 50 mm

Cutting Off

– Firmly clamp the workpiece as appropriate

for its dimensions.

– Adjust the requested horizontal and/or verti-

cal mitre/bevel angle.

– Switch on the machine.

– Press lever 3 and slowly guide the tool arm

downward by handle 1.

– Saw through the workpiece applying uniform

feed.

– Switch off the machine and wait until the

saw blade has come to a complete stop.

– Guide the tool arm slowly upward.

Replacing the Insert Plate

The red insert plate 7 can become worn after

long use of the power tool.

Replace defective insert plates.

– Bring the power tool into the working posi-

tion.

– Unscrew screws 8 using a Phillips screwdriv-

er and remove the old insert plate.

– Insert the new insert plate and and screw all

screws 8 in again.

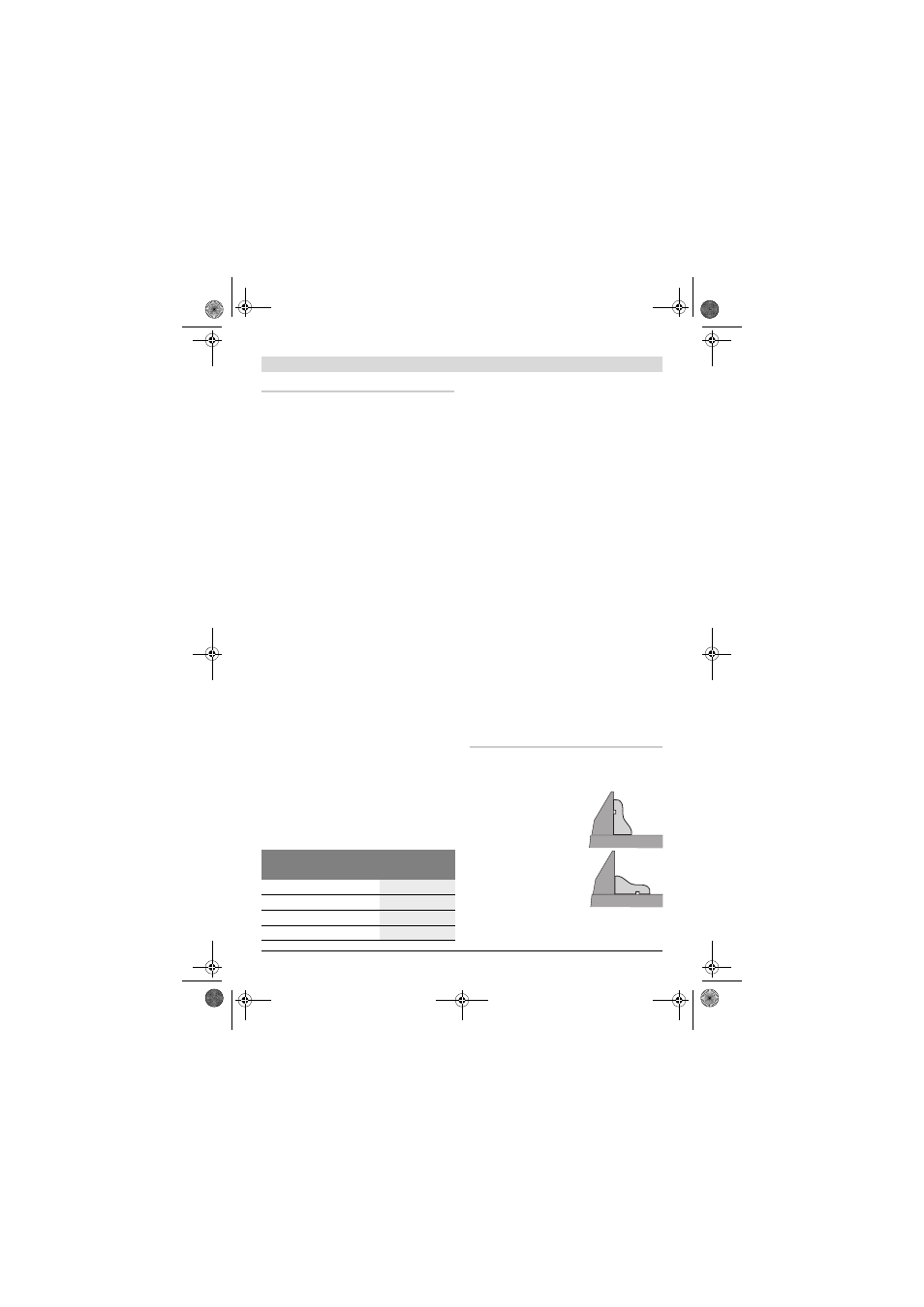

Sawing Profile Strips

Profile strips/mouldings can be sawn in two dif-

ferent ways:

Always make trial cuts with the mitre angle set-

ting first on scrap wood.

Mitre/Bevel Angle

Height x Width

Horizontal

Vertical

0°

0°

50 x 110 mm

45°

0°

50 x 76 mm

0°

45°

37 x 110 mm

45°

45°

37 x 76 mm

– Placed against the fence

– Lying flat on the saw

table

OBJ_BUCH-880-004.book Page 31 Monday, July 19, 2010 11:56 AM