7: scantool setup, 1 basics of computer-controlled cars – Actron CP9110 Scan Tool User Manual

Page 7

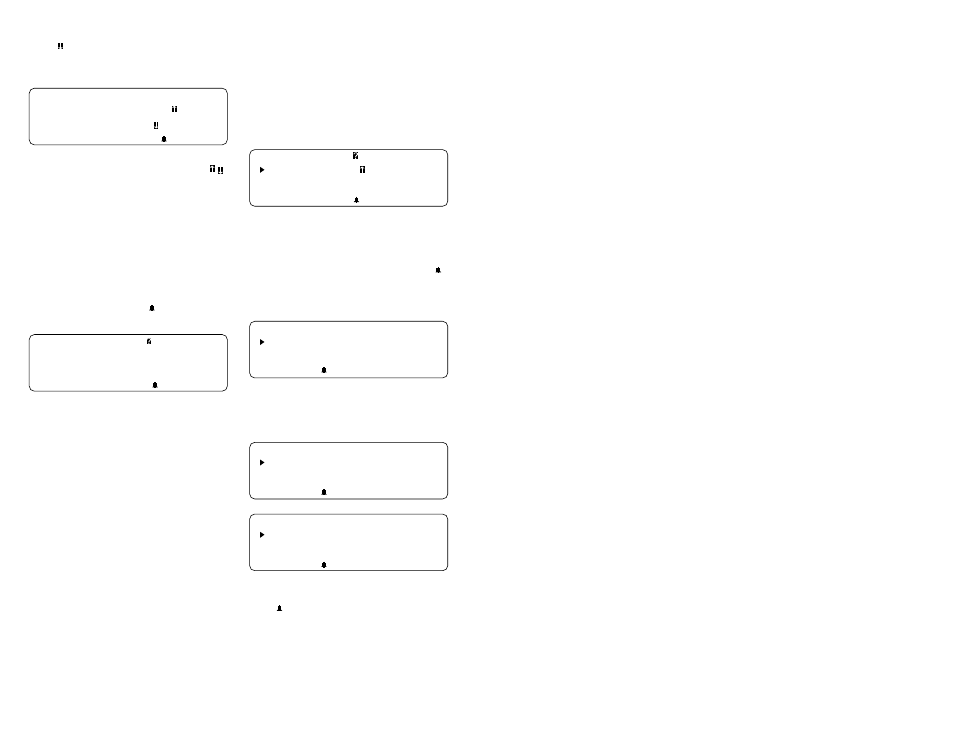

The On-Line Help screen shown above

has a in the last column. To view the next

On-Line Help screen, press the DOWN

arrow key. That screen is shown below:

3. TEST CONNECTOR:

DAMAGED/LOOSE PINS?

4.TOOL SETUP OK?

CORRECT VINS, ETC?

Notice now that both arrow symbols (

)

are visible in the last column of the display.

This indicates that you can either page up

to a previous On-Line Help screen, or

page down to the next On-Line Help

screen by using the UP and DOWN arrow

keys. The previous On-Line Help screen

is always the one you just viewed, just as

with Function Lists.

Another symbol on the screen you might

have noticed is the bell (

) symbol in the

lower right-hand corner as shown below:

Press HELP For Key

Button Information.

Press ENTER To Cont

This bell symbol indicates that the sound

alert is on or active. Each time you press

a key, you should hear a beep. If you do not

see this symbol, then the keys should

remain silent when pressed. Information

on changing this setting is found in section

1-7: Scan Tool Setup.

12

1-7: ScanTool Setup

Tool Setup is used to change the scan

tool’s default sound and measurement

unit settings. To change the scan tool’s

default settings, select the Tool Setup

option from the Function List (NOTE: This

is a GM Function List – Function Lists for

other manufacturers may differ slightly.):

GM Function List

7)Beeper On-Off

8)English-Metric

9)Code Lookup

After selecting the Tool Setup option, you

are given the choice to change either the

ScanTool’s measurement units or whether

the beeper will be On or Off. If the bell (

)

symbol appears in the lower right hand

corner of the display, then the beeper is

turned On.

Setup Tool For

1) English/Metric

2) Beeper On/Off

Depending on whether you select English/

Metric or Beeper On/Off, the ScanTool will

display one of the following screens:

Measurement Units

English (Default)

Metric

Beeper Sound

On (Default)

Off

When the beeper sound is turned Off, the

bell (

) symbol will no longer appear on

the lower right hand corner of the display.

NOTE: If you change the Beeper and

Measurement Units to a setting other than

the default, then all changes will revert

back to the default settings the next time

the scan tool is used.

13

Section 2: Vehicle Computer Basics

2-1

Basics of Computer-Controlled Cars

This section explains the engine com-

puter control system, the types of sensors

and how the computer controls engine

fuel delivery, idle speed and timing. Addi-

tional information may be found in techni-

cal support books at your local library or

auto parts store. The more you know about

the computer system, the better you can

diagnose vehicle computer problems.

Computer controls were originally in-

stalled on vehicles to meet federal gov-

ernment regulations for lower emissions

levels and improved fuel economy. This

began in the early 1980’s when basic

mechanical systems were no longer able

to accurately control key engine param-

eters. A computer could be programmed

to control the engine under various oper-

ating conditions, making the engine more

reliable. While these early systems were

very limited in the scope of their control,

providing only 10-14 trouble codes, they

did help guide the vehicle repair process.

Today, computer controls have made cars

and trucks faster, cleaner, and more effi-

cient than ever before. In fact, without the

government mandates for fuel efficiency

and emissions control, cars and trucks

today would not be nearly as powerful,

reliable, and comfortable as they are.

What the computer controls:

The main control areas of the vehicle

computer are fuel delivery, idle speed,

spark advance, and emissions controls.

Some on-board computers may also con-

trol the transmission, brakes, and suspen-

sion systems as well.

What has not changed?

A computer-controlled engine is very simi-

lar to the older, non-computerized en-

gine. It is still an internal combustion en-

gine with pistons, spark plugs, valves, and

camshaft(s). The ignition, charging, start-

ing, and exhaust systems are very similar

as well. You test and repair these systems

just as before. The technical manuals for

these components show you how to per-

form the tests. Additionally, compression

gauges, vacuum pumps, dwell/tach

meters, engine analyzers, and timing

lights will continue to be used.

The Engine Computer Control system

The vehicle’s on-board computer, or

Powertrain Control Module (PCM), is the

“heart” of the system. It is sealed in a metal

box and connected to the rest of the en-

gine by a main wiring harness. The PCM

is located, in most cases, in the passenger

compartment, behind the dashboard or in

the “kick panel” position, although some

manufacturers locate the computer con-

trol module in the engine compartment

area. Most PCMs can withstand a lot of

vibration and are built to live in a rugged

environment.

The PCM is permanently programmed by

the factory engineers. The program is a

complex list of look-up tables and instruc-

tions telling the computer how to control

the engine based on various driving con-

ditions. To do its job, the computer uses

sensors to know what is happening and

then provide instructions back to a net-

work of switches and actuators through-

out the vehicle.

Sensors, switches, and actuators give

the computer information

Sensors are devices which measure op-

erating conditions and translate them into

signals the computer can understand.