6 installation location, 5 technical data, 7 preparing for unit instal- lation – STIEBEL ELTRON DHF .. C 01.02.2004 - 30.09.2006 User Manual

Page 14

14

2.6 Installation location

The DHF ... C compact control is to

be installed vertically in accordance

with

A

(over-sink or under-sink) in a

closed, frost-free room, as near as possible

to the tap point (a dismantled unit is to be

stored in frost-free conditions, since resi-

dual water always remains in the unit).

Table 3

* Pressure drop values also apply to the minimum flow pressure in accordance with DIN 44851 / Flow rate for heating from 10 °C to 55 °C

(

% # 45 K). A pressure drop of 0.1 MPa (1 bar) is recommended for pipe network dimensioning, in line with DIN 1988 Part 3, Table 4.

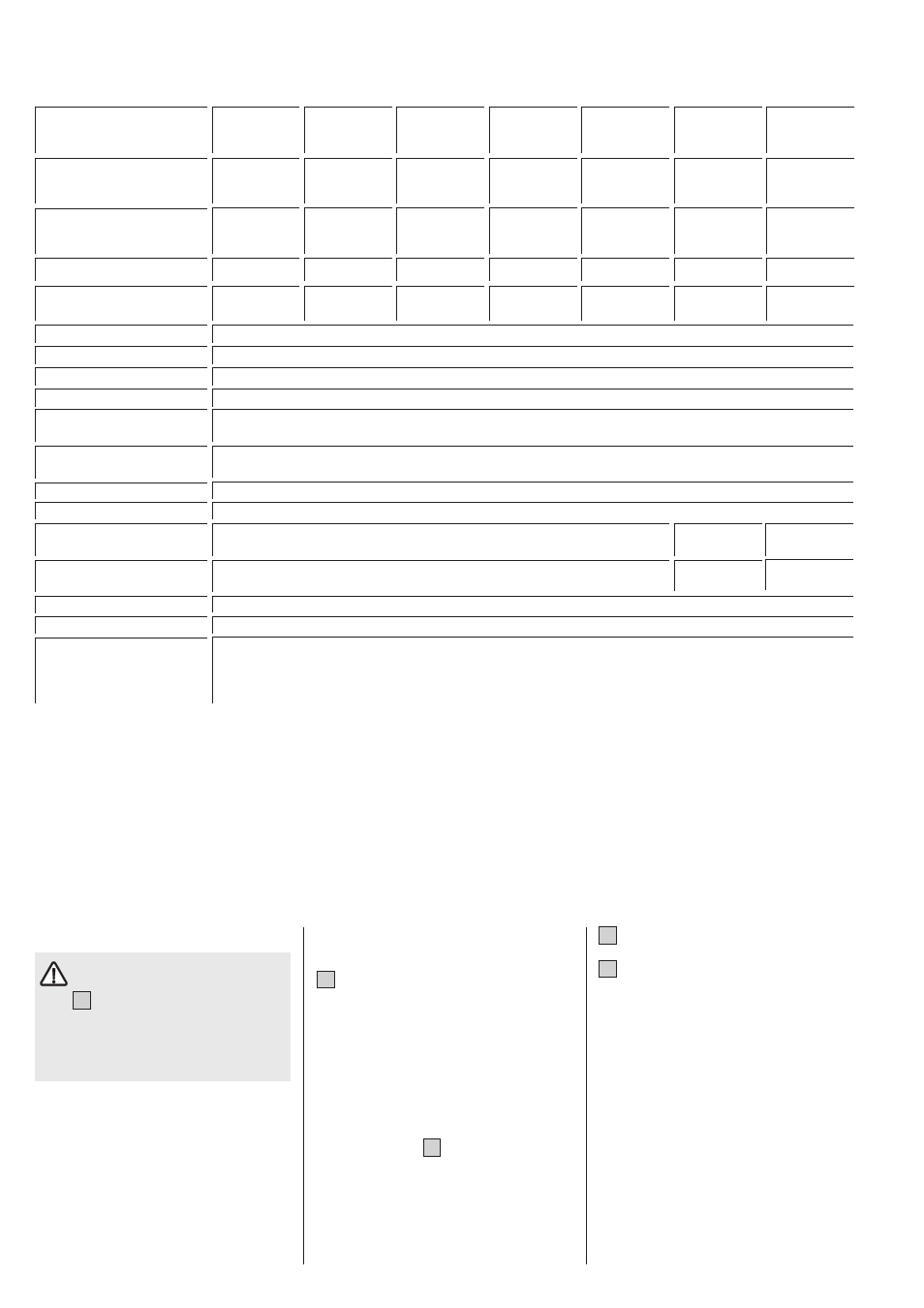

2.5 Technical data

(the data on the unit rating plate are applicable)

Electrical connection

3/PE ~ 400 V

1/N/PE ~

3/PE ~ 230 V

220/230 V

Max. system-impedance

Z max

to DIN EN 61000-3-11

$

0.14

Protection mode to

DIN EN 60529

IP 24

Typ

DHF 13 C

DHF 15 C

DHF 18 C

DHF 21 C

DHF 24 C

DHF 12 C1

DHF 13 C3

compact

compact

compact

compact

compact

compact

compact

control

control

control

control

control

control

control

Heat output

V 400

400

400

400

400

220

230

230

Partial power Stage ! kW

6.6

7.5

9

10.5

12

8

8.8

6.6

Rated power

Stage !! kW 13.2

15

18

21

24

12

13.2

13.2

Min. flow rate to activate unit

Stage ! l/min

3.0

3.0

3.9

4.4

4.9

3.0

3.0

Stage !! l/min

4.5

4.5

5.9

6.4

7.6

4.5

4.5

Flow rate limiter

l/min

6.5

6.5

7.0

7.5

8.0

6.5

6.5

Pressure loss *

MPa (bar) 0.055 (0.55)

0.055 (0.55)

0.06 (0.6)

0.06 (0.6)

0.07 (0.7)

0.055 (0.55)

0.055 (0.55)

Flow rate

l/min 4.5

4.5

5.9

6.4

7.6

4.5

4.5

Nominal water volume

l

0,6

Type of construction

Closed

Rated overpressure MPa (bar)

1 (10)

Weight

kg

4.0

Protection class to

DIN EN 60335

1

Test mark

See unit rating plate

Water connection

G ½ (external thread)

Heating element

Copper tubular heating element

Cold water inlet

& 20 °C

Use in waters

Total alkaline earths

& 2.5 mol/m³

Overall hardness (earlier unit)

& 14 °d

Hardness range (earlier unit)

Inclusive of 2 (medium hard)

2.7 Preparing for unit instal-

lation

B

Turn locking cap (3) to the left and with-

draw.

Unscrew cover securing screw and re-

move device cover.

– Detach mounting bracket (19) from the

unit.

– Thoroughly flush through the cold water

supply pipe.

– In the case of a replacement installation,

the available cold water 3-way three-way

isolating valve (

D

, 6) can if necessary be

used.

– With the help of the template (separate

this from the operating and installation

instructions), determine the position of

the cable entry (concealed connection)

and the mounting bracket (19).

G

Cut the electrical connection cable to

length and strip.

C

Secure the mounting bracket.

When replacing DHF/DHA old models

(height 370 mm), the available drilled

securing holes (20) can be used.

– Secure the unit to mounting bracket with

the screwed sleeve (14). Using the nut

on the threaded bolt (21), unevennesses

in the wall, caused for example by mis-

aligned tiles, can be compensated for

(maximum 12 mm).