Guarantree, Environment and recycling, Affix the type label of the heated mat her e – STIEBEL ELTRON FTD с 06.01.2003 User Manual

Page 11: 4 installation, 5 first start-up, 6 handover

11

English

Heated floor mat

FT

. ...

acc

. DIN 44576

T

ype-No

.:

.. .

. .

.

Pr

od.-No

.:

. .

. .

Rated v

oltage:

230 V

Rated po

w

er

:

...

W

Width of mat:

.,.. m

Length:

.,.. m

Total resistance:

... Ohm

Rated limit temper

ature:

90 ºC

Alter

nating v

oltage sustaining capability 4000

V

Insulation resistance checke

d

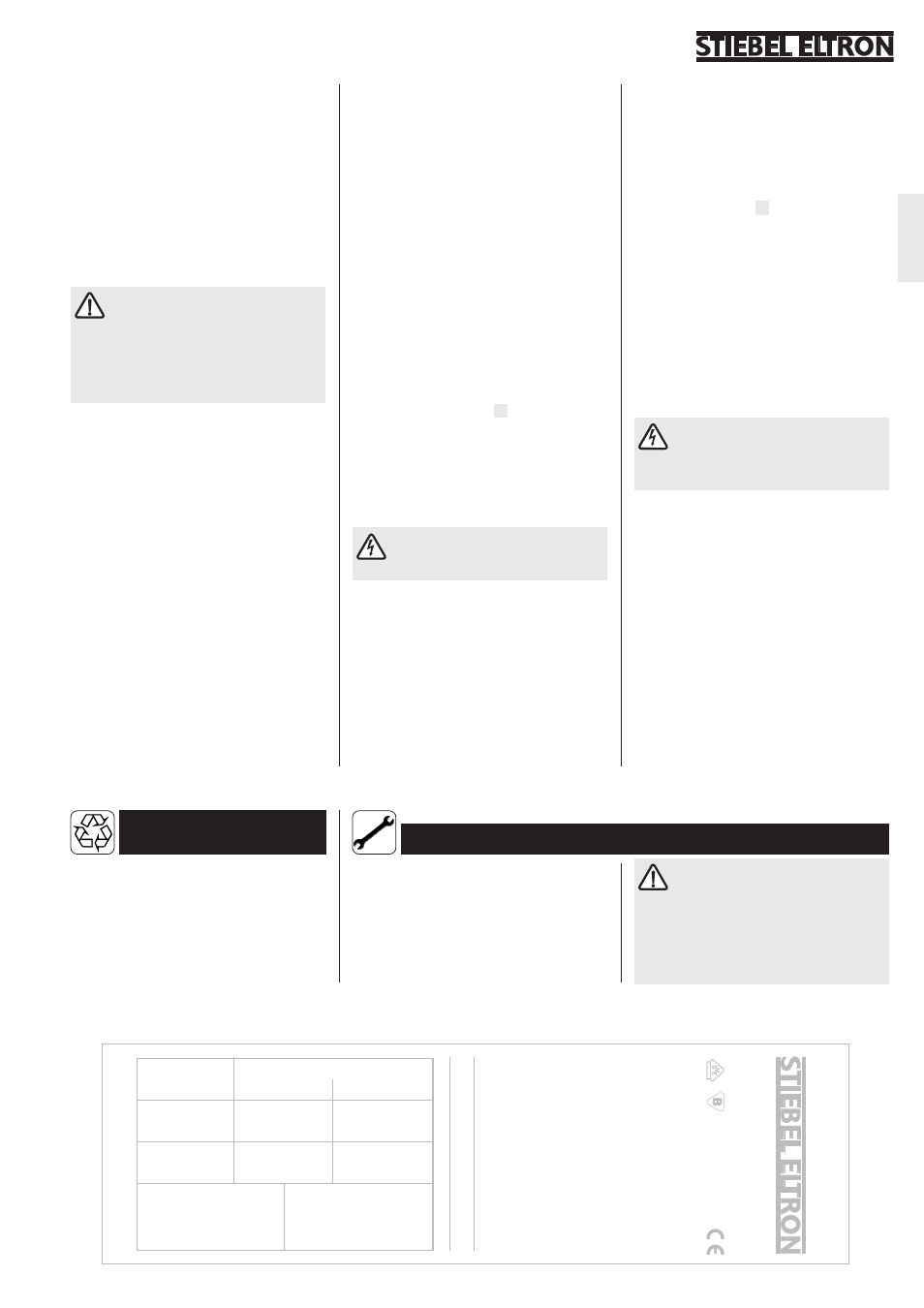

M E A S U R E D D A T A

BEFORE

laying the mat

AFTER

laying the mat

Total resistance

(Ohm)

Insulation

resistance

(megaohms)

Room:

Company:

Date / Signature:

Name :

Please be

war

e back pa

ge

!

Prod.-No

. :

3. Environment and

recycling

For guarantees please refer to the respective

terms and conditions of supply for your

country.

Please help us to protect the environment by

disposing of the packaging in accordance with

the national regulations for waste processing.

The installation, electrical connection

and first operation of this appliance

should be carried out by a qualified installer.

The company does not accept liability for

failure of any goods supplied which are not

installed in accordance with the

manufacturer's instructions.

Affix the type label of the heated mat her

e!

4. Guarantree

This creates an additional built-up height

including the heated mat of 6 to 8 mm. Apply

the desired covering after drying.

In the case of a poorly insulated subfloor or

one which is at risk from cracking, a floor

insulation board should if possible be laid

between the subfloor and the heated mat,

for the purpose of insulating or uncoupling

the heated mat.

2.4 Installation

The type label attached to the heated

floor mats must be filled in, using the

appropriate information, and must be

affixed to these installation instructions.

In the case of FTD series heated floor

mats, all fitted labels are to be removed.

2.4.1 Positioning of the floor

temperature probe

Prior to laying the heated mat, the

temperature probe (6) of the floor

thermostat must be laid. Attention is to be

paid to the following in this process:

The floor temperature probe is to be:

– laid in 11 mm empty trunking centrally

between two parallel heating conductors.

The empty trunking is to be recessed into

the substructure flush with the surface, and

sealed at the end;

– laid at a location which is representative

for the room (e.g. centre of the room), so

that the floor temperature which is set at

the control unit can be adhered to.

If the probe is installed at an unfavourable

location, false temperature measurements

by the probe and associated defective

control actions can occur as a consequence

of the following circumstances:

•

heat build-up - caused by additional

covering of the probe zone, e.g. by

erecting a cupboard

•

covering the largest area of the floor, but

not in the probe zone

•

continual draught through an open

window

For this, the operating and installation

instructions for the thermostat are to be

noted.

2.4.2 Laying the mat

Lay out the heated floor mat(s). To make

work easier, it is recommended that the

heated mat(s) is/are fixed in position using

securing pegs (5, special accessories).

By separating the reinforced glass fabric, it is

possible to lay several heating paths, accord-

ing to requirements (see

D

). Thus, for

example, the PTC connectors can also be

laid closer to the mains supply point

(thermostat). Attention must be paid to

ensuring that the heating paths do not cross

and that the heating lines are not bent or

twisted.

It is only the fabric (2) which may be

separated, the heating lines (1) must

not be severed under any circumstances.

After laying and any fixing of the heated mats,

the two PTC connectors (4) are to be laid

to the connection box of the thermostat, for

example through trunking.

During and after laying, the heated mats are

to be stepped on only to the extent which is

absolutely necessary, to avoid mechanical

damage. If necessary, special measures are to

be taken in this regard, for example wearing

shoes with rubber soles and placing and

moving the requisite equipment (tools) on

suitable supports.

2.4.3 Electrical connection

The electrical connection of the heated floor

mat is to be carried out in accordance with

the connection plan (

C

) in these installation

instructions.

Before and after the electrical connection of

the heated mat(s), the insulation resistance,

the continuity of current, and the resistance

value are to be measured.

The maximum permissible current in the

case of parallel connection of several heating

mats amounts to 10 A.

It is absolutely imperative to note the rated

current of the thermostat!

The protective braiding of the PTC

connectors serves to earth the

heated mats and must be connected to the

earth terminals of the thermostat.

2.5 First start-up

On the occasion of the first start-up, the

floor heating is to be heated up briefly

several times, since cracks in the top covering

can otherwise arise.

2.6 Handover

Explain the functions of the heated mat and

the thermostat to the user. Make him or her

aware of the safety instructions, in particular.

Hand over the operating and installation

instructions to the user, as well as the type

label. This is held to be a guarantee

document and must be retained.