RIDGID RB-3W User Manual

Page 5

2

3

2

3

PROBLEM SOLVING DRY AND WET DRILLING

1. Diamond core does not cut

- Core is glazed or not sufficiently dressed: redress with

sharpening stone.

- Problem with bit or machine: check and replace when

necessary.

2. Diamond drill does not cut or drills too slowly

- RPM too high or too low: check speed.

- Insufficient feed pressure.

- Diamond bit is glazed or polished: use sharpening stone.

- When dry drilling: material is too hard to drill dry.

- When wet drilling: a lot of steel is being drilled: continue

slowly, give the core bit the time to drill through the steel.

3. Diamond core jams in the hole

- Operator is not holding the drill straight enough.

- The drilling debris is not cleared regularly and is jamming

the core bit: use dust extractor.

- Diamond bit is bent (damaged): check and replace.

- Wet drilling: inadequate water supply.

- Motor clutch set is worn out: replace.

4. Diamond core is wearing too quickly

- Incorrect drilling speed: check RPM. Try next faster speed.

- Excessive feed pressure: reduce force.

- Wet drilling: insufficient water.

- Wet drilling: Material is very abrasive and/or heavily

reinforced: use special bit.

- Drilling machine not held steadily.

- Drilling machine is hammering: don’t use the hammering

system for core drilling.

5. Segments of the diamond core are losing side clear-

ance

- Drilling machine not held steadily.

- Bit spindle or adapters are damaged.

- Core bit is damaged or bent.

- Insufficient water.

- Material is too abrasive: use special bit.

- Dry drilling: Cutting/drilling dust is building up and

jamming the core: regularly clear the hole or use the dust

extraction.

6. Segment loss

- Core bit doesn’t run concentric.

- Drilling/cutting debris is building up and is jamming the

core.

- Material cannot be drilled dry.

- Core bit is being forced too hard: reduce feed pressure.

- Insufficient cooling water.

7. Segments are folding in or out

- Excessive pressure.

- Too high speed.

- The drilling machine is left on “hammer”.

8. Core is lodged within the diamond bit

- The heat has expanded the material which is now lodged in

the bit: let it cool down, eventually use water.

- The core has broken within the diamond bit: remove core.

- The bit has lost its side clearance: check that the bit,

machine etc. is running concentric. If necessary retip the

diamond bit.

9. No water flowing out of the bore hole (wet drilling)

- Water swivel, drill spindle or water supply are blocked; free

the blockage.

- Material within bit is blocking the water: remove core from

the bit.

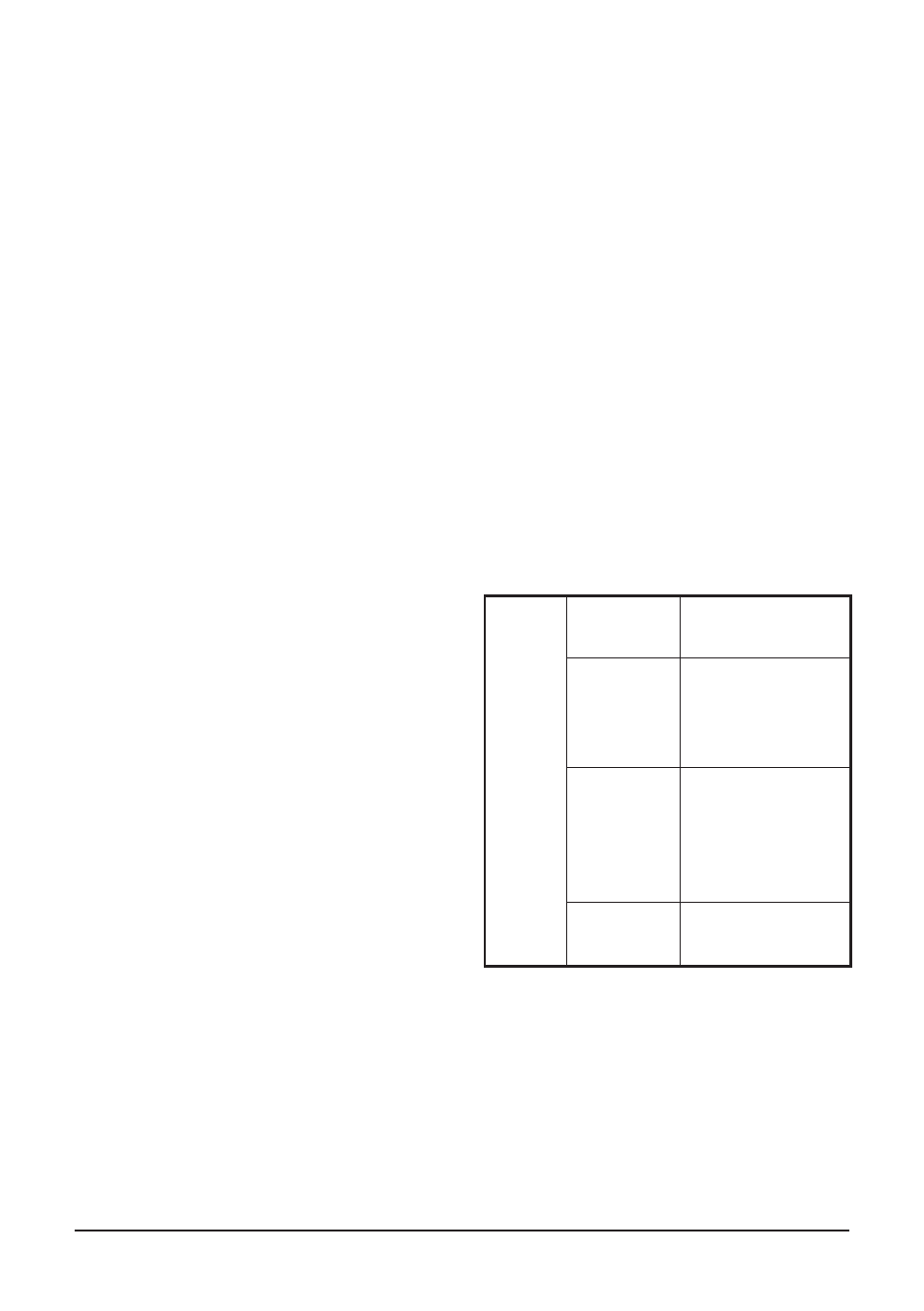

OVERLOAD PROTECTION

HC-2W,

RB-3W

Mechanical:

Clutch will disengage if the

drill bit is blocked.

Thermal:

If unit is continuously

overloaded the thermal

overload will disconnect

the supply.

Electronic:

Electronic protection will

disconnect supply if unit is

overloaded. After unit has

stopped remove load and

restart.

Red LED:

This lights up when you

overload the motor.