Machine assembly, Machine inspection, K-1000 rodder – RIDGID K-1000 User Manual

Page 6: Warning, Instructions for engine, Instructions for assembling rods and tools

6

K-1000 Rodder

The following Heavy-duty Cable Tools are also

recommended for use with rod.

Catalog

No.

Model

No.

Description

Replacement

Blade(s)

61800

T-2

Heavy-Duty Straight Auger

—

61790

T-4

Heavy-Duty Funnel Auger

—

63200

T-7

Hook Auger

—

61960

T-16

Spiral Bar Cutter, 4” (100 mm)

97855

61850

T-17

Spiral Bar Cutter, 6” (150 mm)

97955

61855

T-18

Spiral Bar Cutter, 8” (200 mm)

97960

63085

T-23

Spiral Sawtooth Cutter,

4” (100 mm)

97850

59765

T-24

4-Blade Cutter, 2

1

/

2

” (65 mm)

97940

59770

T-25

4-Blade Cutter, 3

1

/

2

” (90 mm)

97975

59775

T-26

4-Blade Cutter, 4

1

/

2

” (115 mm) 97805

59780

T-26A

4-Blade Cutter, 5

1

/

2

” (140 mm) 97980

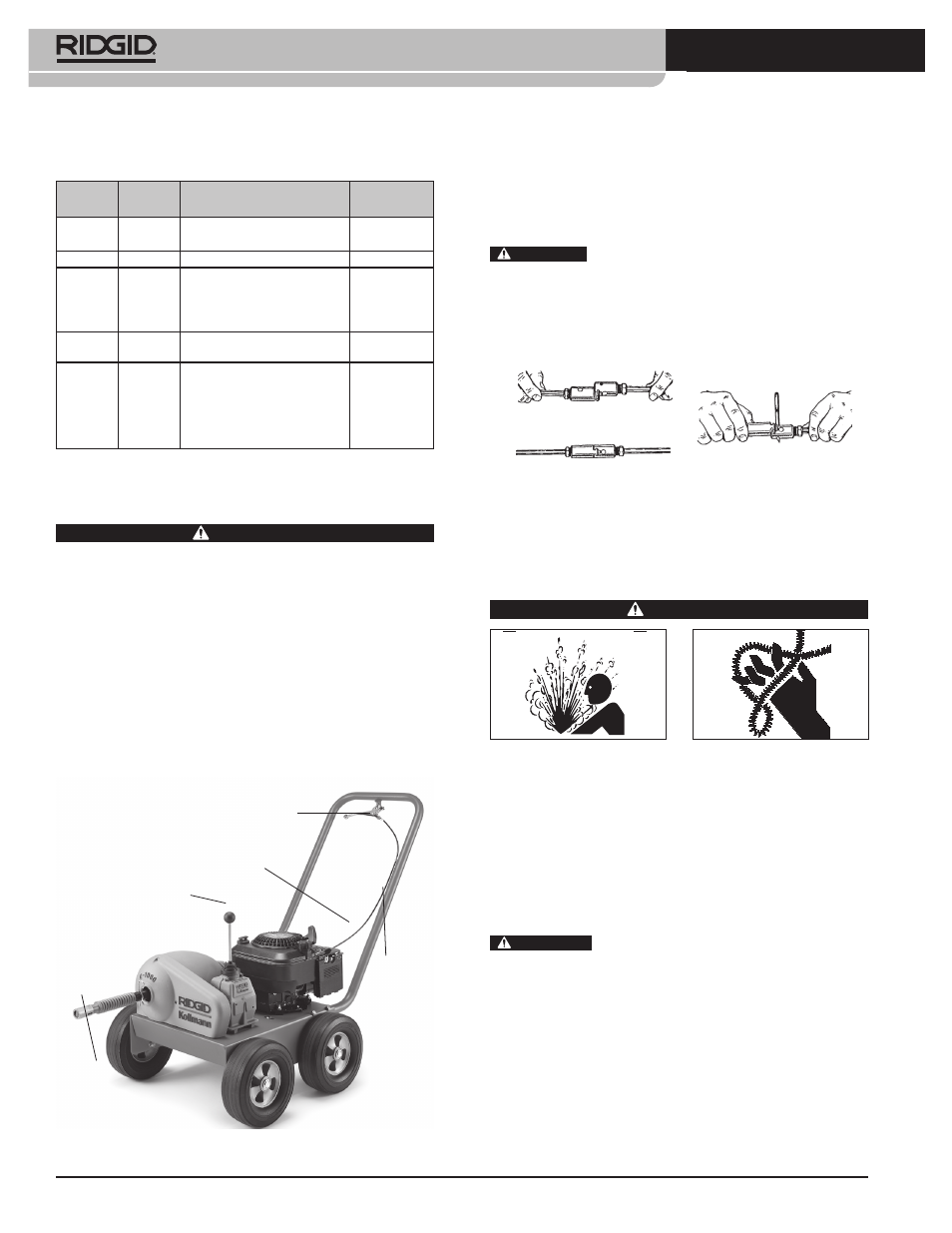

Machine Assembly

WARNING

To prevent serious injury, proper assembly of the

K-1000 Rodder is required. The following proce-

dures should be followed:

Instructions for Installing Handle and

Throttle Cable

1. Insert handle assembly into handle openings in

base and attach by means of four

3

/

8

” bolts provid-

ed (Figure 1).

2. Attach free end of throttle cable to throttle handle

and secure cable to left side of handle with two

cable clamps provided.

Throttle Cable Handle

and Stop Nut

Throttle Cable

Shift Lever

Handle

Assembly

Rod Holder

Figure 1

Instructions for Engine

1. Engine is shipped without oil. Fill with oil prior to

starting engine (See enclosed Engine Owner’s Man-

ual for details).

CAUTION

Failure to fill engine with oil will result in

engine failure.

Instructions for Assembling Rods and Tools

1. To connect rods, align and snap the couplings to-

gether for a solid connection (Figure 2).

Figure 2 – Connecting/Disconnecting Rods

2. To disconnect, insert pin key and slide couplings

apart.

Machine Inspection

WARNING

To prevent serious injury, inspect your Rodder. The

following inspection procedures should be per-

formed on a daily basis:

1. Check engine crankcase oil level. If low, add oil (see

enclosed Engine Owner’s Manual for details).

2. Check engine fuel level. If low, add unleaded gaso-

line with a pump octane rating of 86 or higher. (See

enclosed Engine Owner’s Manual for details).

WARNING

Use caution when handling gasoline. Re-

fuel in well-ventilated area. Do not over fill fuel tank and

do not spill fuel. Make sure tank cap is closed properly.

3. Inspect the rodder for any broken, missing, mis-

aligned or binding parts as well as any other con di-

tions which may affect the safe and normal opera-

tion of the machine. If any of these conditions are

present, do not use the Rodder until any problem

has been repaired.