Caution, Warning – Festool BMS 180 E Rustofix HR User Manual

Page 14

14

full load. The machine requires less time to cool

down when idling.

LED indicator

The rotary sander is fitted with an electronic

adjusting wheel and a green and red LED [1-3].

A green lit LED indicates that the rotary sander

is operating in normal mode. A red lit LED indi-

cates that the motor is operating at approx. 70%

overload. The overload or temperature cut-out

switches off the motor if overloaded for longer

periods.

However, alternately fl ashing green and red LEDs

indicate that the brushes are completely worn

(remaining working hours max. 10 hours). In

this case, have an authorised after-sales service

workshop replace the carbon brushes the next

day. Always replace these brushes with special

carbon brushes available in pairs otherwise the

LED indicators will not work.

7.2 Changing the brushes

Loosen the screw [2-1].

Swivel the silver cover [2-2] down.

Press and hold the spindle lock [2-3] and un-

screw the hexagon nut (size 24) on the brush.

Insert a different brush.

Tighten the hexagon nut to secure the brush

and then close the silver cover.

For brushes LD 85 and BG 85, use the ac-

companying centring disc.

7.3 Adjusting the texture depth

Set the required texture depth using the thum-

bwheel [1-6].

7.4 Dust

extraction

CAUTION

Breathing in dust damages the respiratory

passage.

Always connect the machine to a dust ex-

tractor.

When performing work that generates dust,

always wear a dust mask.

You can connect a Festool extractor to the extrac-

tor connector [1-7]. The extractor hose in the

Festool extractor is 27 mm in diameter.

8

Working with the machine

The RUSTOFIX gives beams or wooden panelling

a rustic texture.

Working method

After the fi rst working procedure with the wire

brush LD 85, protruding fi bres give the wooden

surface a rough feel. In the second working pro-

cedure, plastic bristles KD 80 sand the textured

surface to lend a smooth fi nish.

Always guide the machine evenly and in the

direction of the grain.

Hold the machine with both hands to ensure

safe guidance.

Do not overload the machine by pressing with

excessive force! The best results are achieved

with moderate application pressure.

Maintain the speed specified. (see Chapter

7.1)

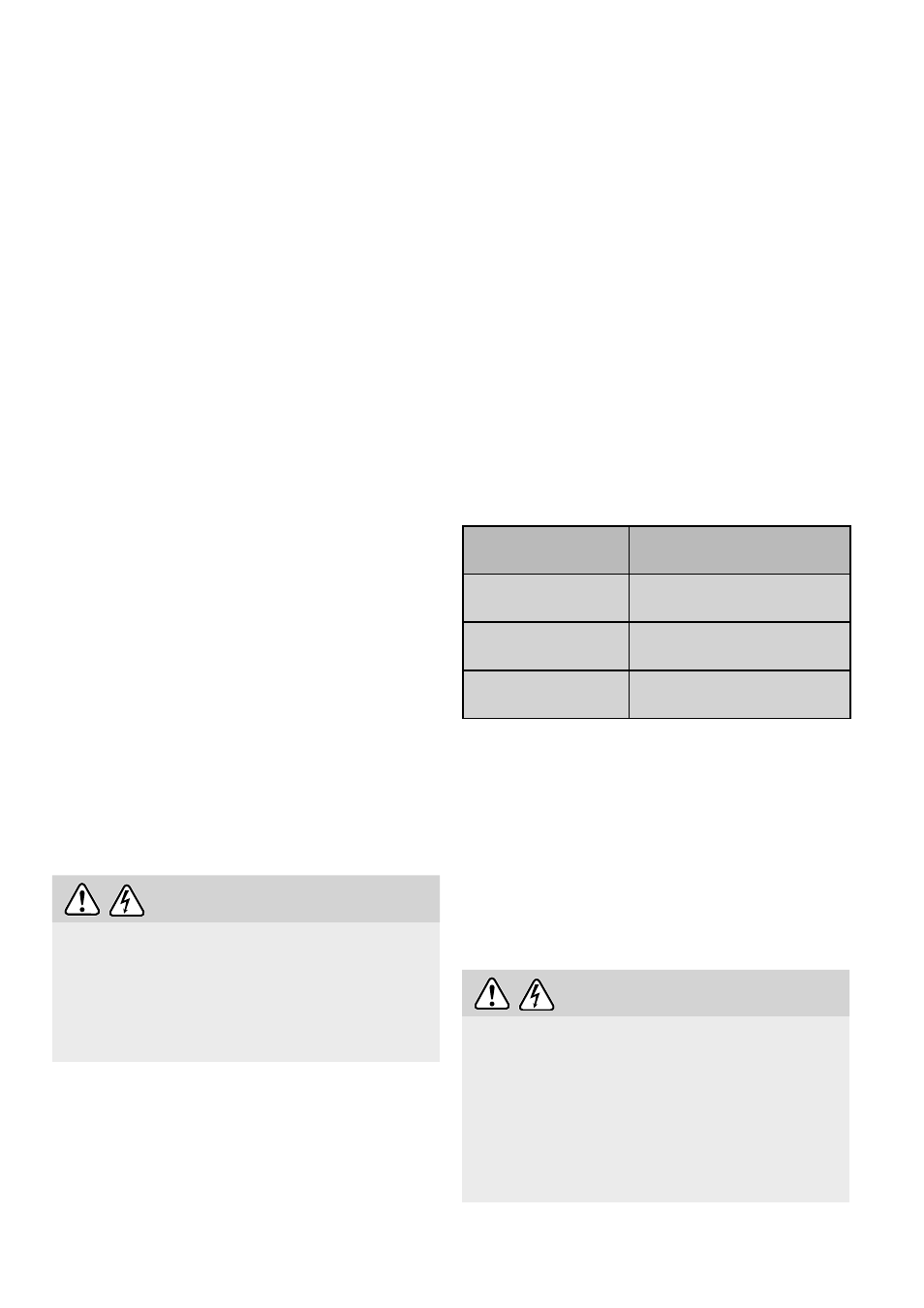

Use the correct brush for the relevant working

procedure:

Working proce-

dure

Brush

Texturing

Rustilon brush LD 85

(standard wire brush)

Intermediate san-

ding

Rustilon brush KB 80

(plastic bristles)

Smoothing

Rustilon brush BG 85 (si-

sal bristles)

Note

• Do not use the KD 80 brush with plastic bristles

for texturing. The brush is not suitable for

heavy-duty texturing.

• The BG 85 is the only brush suitable for proces-

sing stained or oiled parts. All other brushes

will be damaged.

9

Service and maintenance

WARNING

Risk of accident, electric shock

Always pull the plug out of the socket be-

fore performing any type of work on the ma-

chine.

All maintenance and repair work which re-

quires the housing to be opened must only

be carried out by an authorised service work-

shop.