Installation guide ame 55, ame 56, Disposal instruction, Dimensions ❶ mounting – Danfoss AME 56 User Manual

Page 4: Wiring, Dip switch settings

4

safety note

To avoid injury and damage to persons

and devices, it is absolutely necessary

these instructions are carefully read

and observed prior to assembly and

commissioning.

Necessary assembly, start-up, and

maintenance work must be performed

only by qualified, trained and authorised

personnel.

Prior to assembly and maintenance work

on the controller, the system must be:

- depressurised

- cooled down

- emptied

- cleaned

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover before the power

supply is fully switched off.

Disposal instruction

This product should be

dismantled and its

components sorted, if

possible, in various groups

before recycling or disposal.

Always follow the local disposal

regulations.

Dimensions

❶

Mounting ❷

Fix the actuator AME 55, AME 56 on the

valve

❸

.

Wiring ❹

Do not touch anything on the PCB!

Switch off the power line before wire the

actuator! Lethal voltage!

Wire the actuator according to the wiring

diagram.

Control signal

Control signal from the controller must be

connected to terminals Y (input signal) and

SN (common) on the AME printed board.

Output signal

Output signal from the terminal X can be

used for indication of the current position.

Range depends on the DIP switch settings.

supply voltage

Supply voltage (24 V~ -15 to +10%, 50 Hz)

must be connected to the terminals SN

and SP.

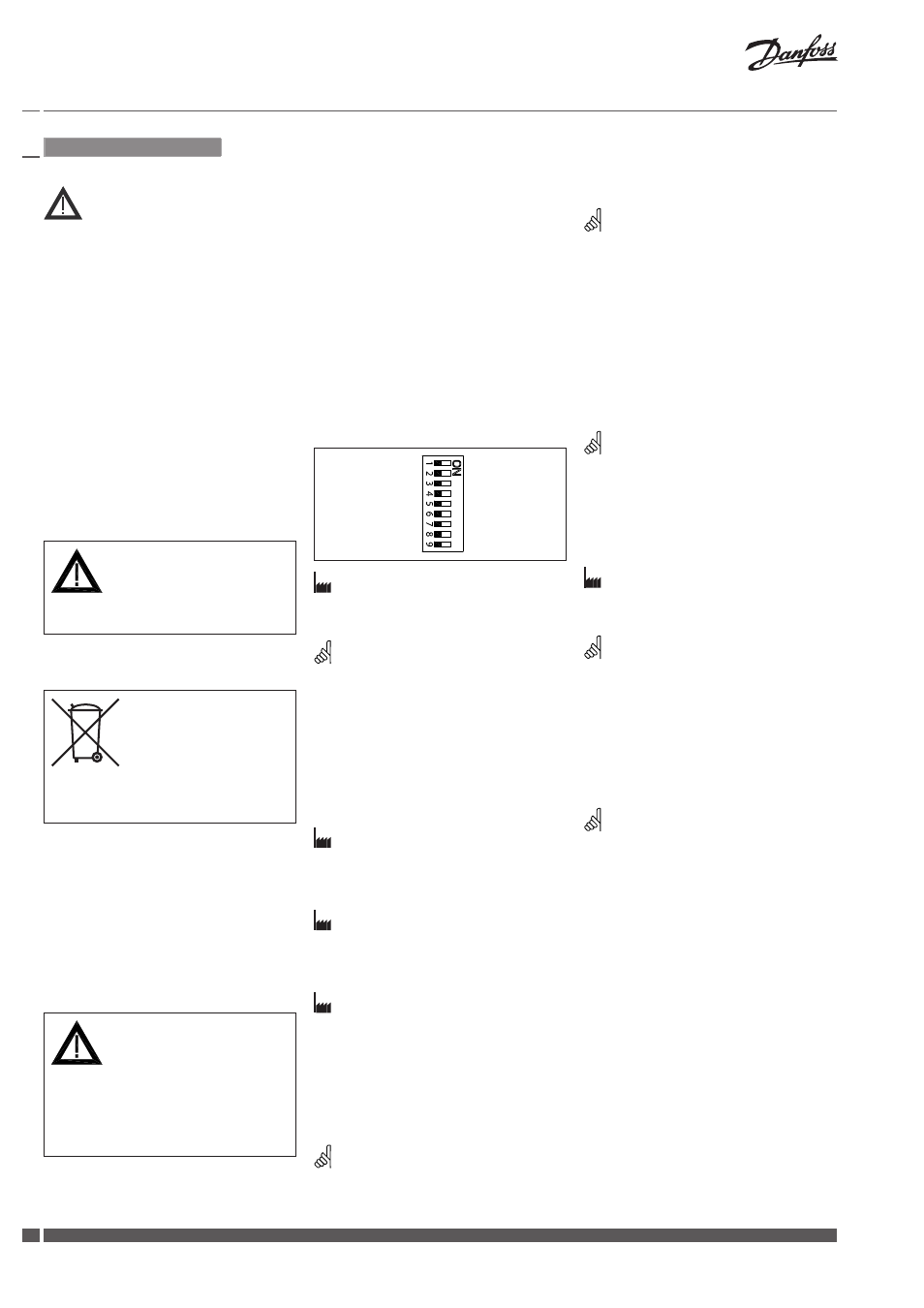

DIP switch settings ❺

U

I

2 V_--- V

0 V_--- V

Direct

Inverse

---

Sequential

0(2)_5(6) V

5(6)_10 V

Proportional

3 point/RL

LOG. flow

LIN. flow

100 % k

VS

RED. k

VS

Reset

Reset

Factory settings:

ALL switches are on OFF position! ①

Note:

All combinations of DIP switches are

allowed. All functions that are selected are

added consecutively. There is only one logic

override of functionalities i.e. the switch No.6

Proportional/3 point, which sets actuator to

ignore control signal and works as a “simple”

3-point actuator.

sW 1: U/I ②

Factory setting:

voltage control signal (0-10 V).

sW 2: 2-10 V/0-10 V ③

Factory setting is:

2-10 V.

sW 3: Direct/Inverse ④

Factory setting is:

DIRECT

sW 4:---/sequential ⑤

Two actuators can be set to work parallel

with one control signal. If the SEQUENTIAL

is set than an actuator responds to split

control signal (see 0(2)-5(6) V/5(6)-10 V).

Note:

This combination works in combination with

switch No. 5: 0(2)-5(6) V/5(6)-10 V

sW 5:

0(2)-5(6) V/5(6)-10 V ⑥

Note:

This function is available if switch No. 4:

--- / Sequential is set.

sW 6: Proportional/3 point ⑦

Actuator can operate as “simple” 3-point

actuator, if the 3-point function is selected.

Power supply should be connected on

SN and SP ports. On port 1 or 3 24 VAC

signal is connected for rising or lowering

of actuator. Return signal X indicates the

correct position.

Note:

if 3 point function is selected actuator does

not respond to any control signal on port Y.

It only rises and lowers spindle if power is

supplied on port 1 or 3.

sW 7: lOG. flow/lIn. flow ⑧

Factory setting is:

LOG. Flow (characteristic of valve is

unchanged)

Note:

If this function is used in combination with

non-logarithmic valves the characteristic

of motorised valve will be anti-logarithm

of valve’s characteristic (e.g. valve with

linear characteristic will be transformed to

quick open characteristic).

sW 8: 100% K

Vs

/RED. K

Vs

⑨

Note:

This function works proper only with

logarithmic (equal percentage) valves.

sW 9: Reset ⑩

After the actuator has been connected

to power supply, the actuator will start

the self-adjustment procedure. The

indicator LED flashes until self adjustment

is finished. The duration depends on the

spindle travel and will normally last a few

minutes. The stroke length of the valve is

stored in the memory after self adjustment

has been completed. To restart self

adjustment, change the position of RESET

switch (switch No. 9). If the supply voltage

is switched off or falls below 80 % in more

than 0.1 s, the current valve position will be

stored in the memory and all data remain

saved in the memory also after a power

supply cut-out.

Installation Guide

AME 55, AME 56

DH-SMT/SI

EI.98.B3.2V

Danfoss Heating

lAnGUAGE

EnGlIsh