3M Series 56ZZ User Manual

Page 21

20

Spray Gun Care and Cleaning cont.

ATTENTION

Solvent left in the spray gun air passages could result

in a poor quality paint finish. Do not use any cleaning

method which may allow solvent into the spray gun air

passages. Do not expose air regulators and gauges to

solvent as damage may occur.

Cleaning Process

1. Relieve the pressure from the spray gun before

servicing.

2. Refer to your fluid source manual for removal and

cleaning.

3. To retain unused material or temporarily store mixed

material, see your Local, State, Federal and OSHA

guidelines, along with material manufacturer’s

recommendations for storage.

4. Flush the spray gun. To flush spray gun, run water or

compatible and compliant solvent into the spray gun

fluid passage while triggering the

spray gun.

5. Remove the retaining ring and air cap.

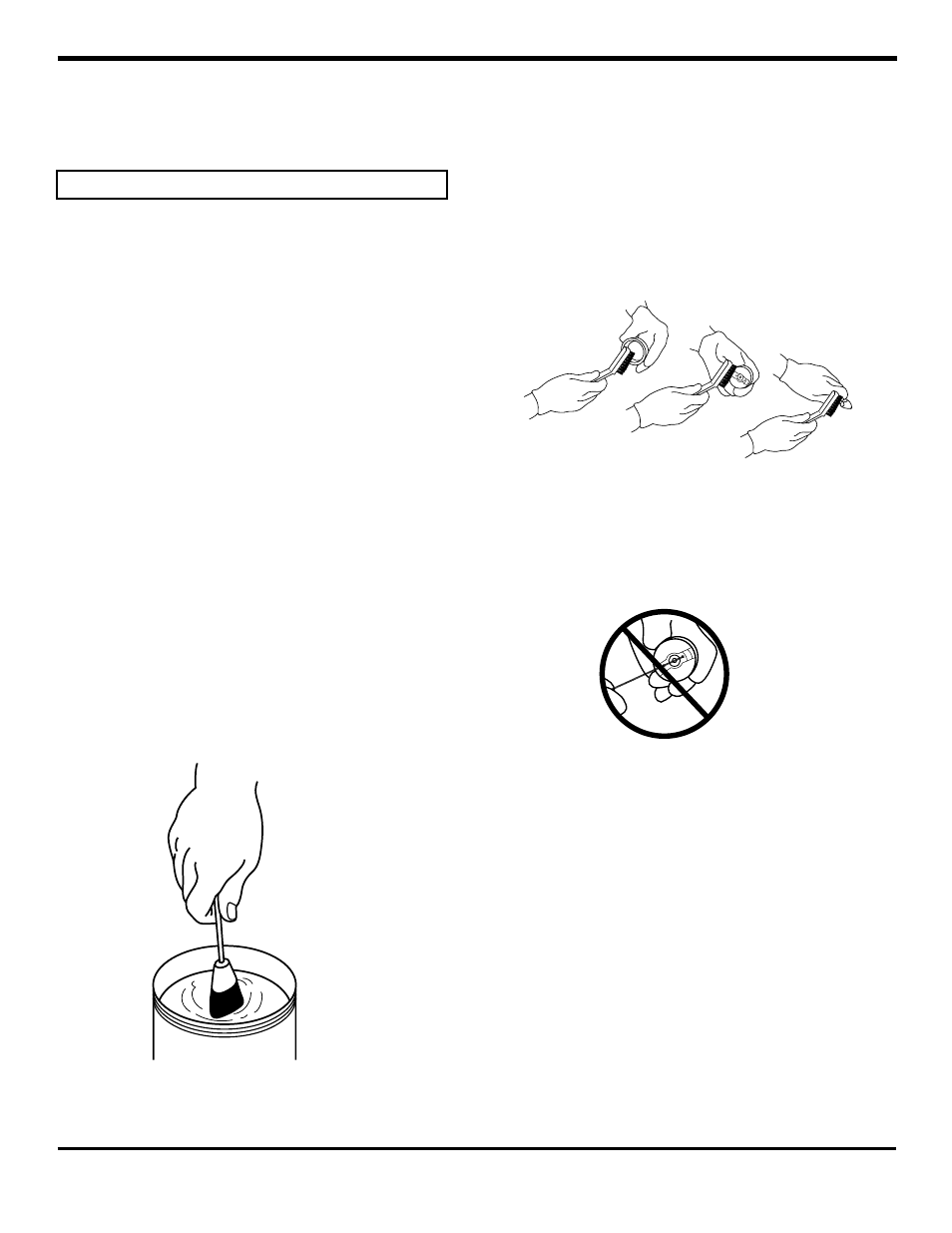

6. Unscrew the fluid needle tip with fingers.

7. Dip the end of a soft-bristle brush into a compatible

solvent. Do not continuously soak the brush’s bristles

with solvent, and do not use a wire brush.

8. Clean the front of the spray gun, using a soft-bristle

brush and solvent.

9. Scrub the retaining ring, air cap and fluid nozzle

with a soft-bristle brush. To clean out air cap holes,

use a small brush.

10. Clean the air cap and fluid nozzle after each use. Do not

use metal tools to clean the air cap holes as this may

scratch them; scratches can distort the spray pattern.

Do not soak the retaining ring in solvent for prolonged

periods of time.

11. Thread fluid needle tip on finger tight. Tighten the

nozzle securely to obtain a good seal.

12. Install the retaining ring and air cap.

13. Dampen a soft cloth with solvent and wring-out the

excess. Wipe off the outside of the spray gun.

3