York STYLE A YCWS User Manual

Page 41

FORM 201.24-EG1

41

YORK INTERNATIONAL

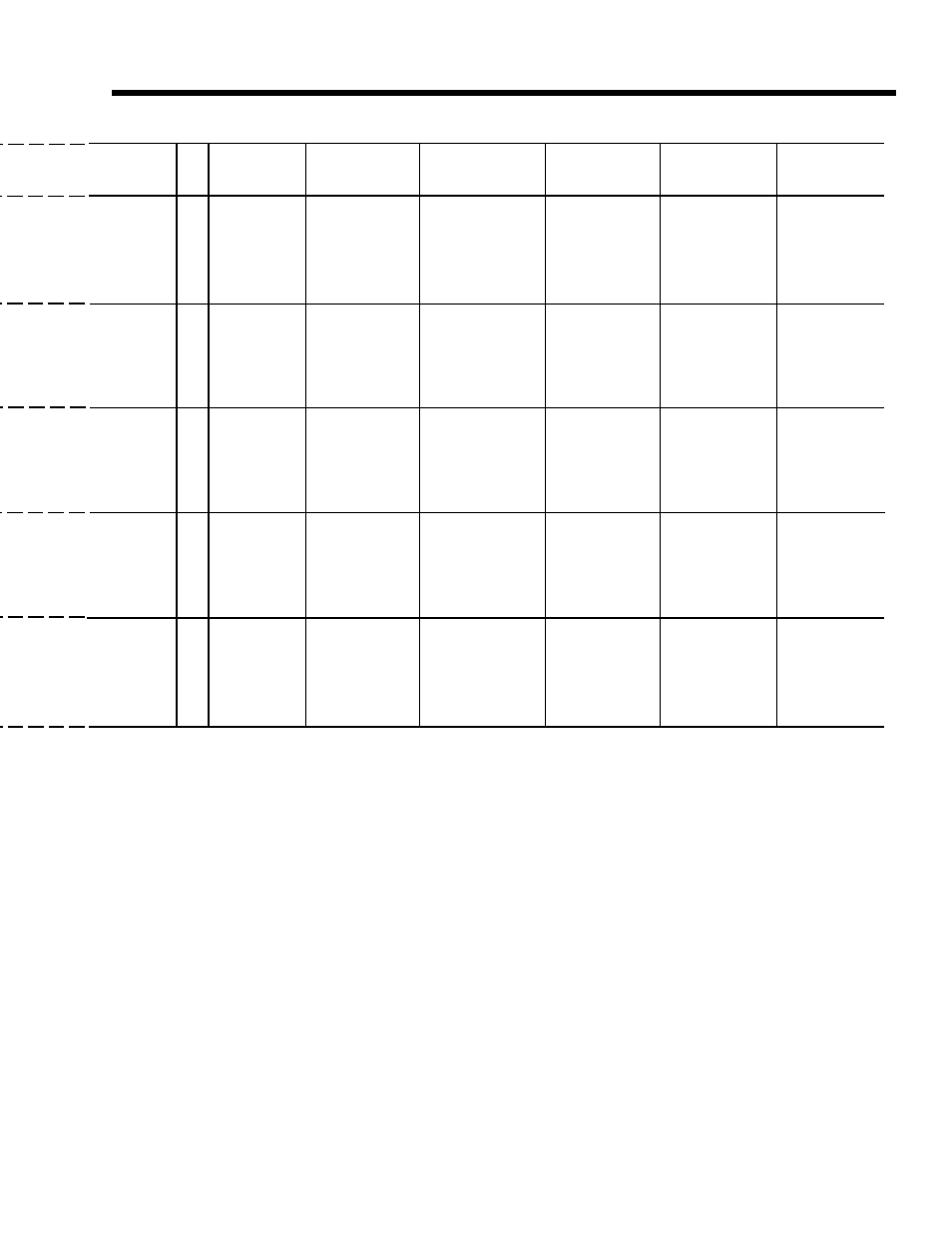

MULTIPOINT WIRING SYSTEM #2

YCWS0100SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

YCWS0120SC

#2/0 - 500 KCM

# 4 - 3/0 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0140SC

#2/0 - 500 KCM

# 4 - 3/0 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0180SC -17 #2/0 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0200SC

#2/0 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0220SC

(2) #2 - 4/0 AWG (2) # 6 - 1/0 AWG

(2) #3/0 - 250 KCM

# 4 - 3/0 AWG

(3) 2/0 - 400 KCM

(2) # 2 - 4/0 AWG

YCWS0240SC

(2) #2 - 4/0 AWG (2) # 6 - 1/0 AWG

(2) #3/0 - 250 KCM

# 4 - 3/0 AWG

(3) 2/0 - 400 KCM

(2) # 2 - 4/0 AWG

YCWS0100SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0120SC

#2 - 300 KCM

# 6 - 1/0 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

#4 - 300 KCM

# 4 - 3/0 AWG

YCWS0140SC

#2 - 300 KCM

# 6 - 1/0 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

#4 - 300 KCM

# 4 - 3/0 AWG

YCWS0180SC -28 #2/0 - 500 KCM

# 4 - 3/0 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0200SC

#2/0 - 500 KCM

# 4 - 3/0 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0220SC

#2/0 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0240SC

#2/0 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

250 - 500 KCM

# 4 - 3/0 AWG

YCWS0100SC

#6 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

YCWS0120SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0140SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0180SC -40

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0200SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0220SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

YCWS0240SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

YCWS0100SC

#6 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

YCWS0120SC

#6 - 1/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

YCWS0140SC

#6 - 1/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

YCWS0180SC -46

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0200SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0220SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0240SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#4 - 300 KCM

# 6 - 1/0 AWG

YCWS0100SC

#18 - 2 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

YCWS0120SC

#6 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

#2 - 4/0 AWG

# 8 - 2 AWG

YCWS0140SC

#6 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

#2 - 4/0 AWG

# 8 - 2 AWG

YCWS0180SC -58

#6 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

YCWS0200SC

#6 - 1/0 AWG

# 8 - 2 AWG

#14 - 1/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

YCWS0220SC

#6 - 1/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

YCWS0240SC

#2 - 4/0 AWG

# 8 - 2 AWG

#4 - 300 KCM

# 8 - 2 AWG

#6 - 350 KCM

# 6 - 1/0 AWG

CHILLER

MODEL

VOLT

CODE

TERM

BLK

TERMINAL BLK

CUSTOMER

GROUND

N-F DIS

SW

N-F DIS SW

CUSTOMER

GROUND

CKT.BRKR

CKT.BRKER

CUSTOMER

GROUND

5. Circuit breakers supplied by third party vendors must be certified by local electrical standards. Maximum size is

based on 225% of the rated load amps for the largest motor plus 100% of the rated load amps for all other loads

included in the circuit.

6. The “INCOMING WIRE RANGE” is the minimum and maximum wire size that can be accommodated by the unit

wiring lugs. The (2) preceding the wire range indicates the number of termination points available per phase of

the wire range specified. Actual wire size and number of wires per phase must be determined based on the

National Electrical Code, using copper connectors only. Field wiring must also comply with local codes.

7. A ground lug is provided for each compressor system to accommodate a field grounding conductor per N.E.C.

Table 250-95. A control circuit grounding lug is also supplied.

8. The supplied disconnect is a “Disconnecting Means” as defined in the N.E.C. 100, and is intended for isolating

the unit for the available power supply to perform maintenance and troubleshooting. This disconnect is not

intended to be a Load Break Device.

9. Field Wiring by others which complies to the National Electrical Code & Local Codes.