Maintenance – York WORLD 50 HZ K3EU180A50 User Manual

Page 8

MOTOR SPECIFICATIONS

•1450 RPM

•380/415-3-50

•Solid base

•56 Frame

•Inherently protected

•Permanently lubricated

ball bearings

MAINTENANCE

FILTERS — The filters must be replaced as often as necessary

to assure good air flow and filtering action.

EVAPORATOR COIL — Do not allow dirt to accumulate on the

evaporator coil or other parts of the evaporator air circuit. Clean

as often as necessary to assure good system performance.

Use a brush, vacuum cleaner attachment or other suitable

means.

LUBRICATION — The bearings for the blower shaft and the

blower motors are permanently lubricated and should not re-

quire additional lubricant.

DRAIN PAN — The drain pan should be inspected regularly

to assure proper drainage.

BELTS — Maintain belt tension to extend belt life. Replace

when signs of failure begin to appear.

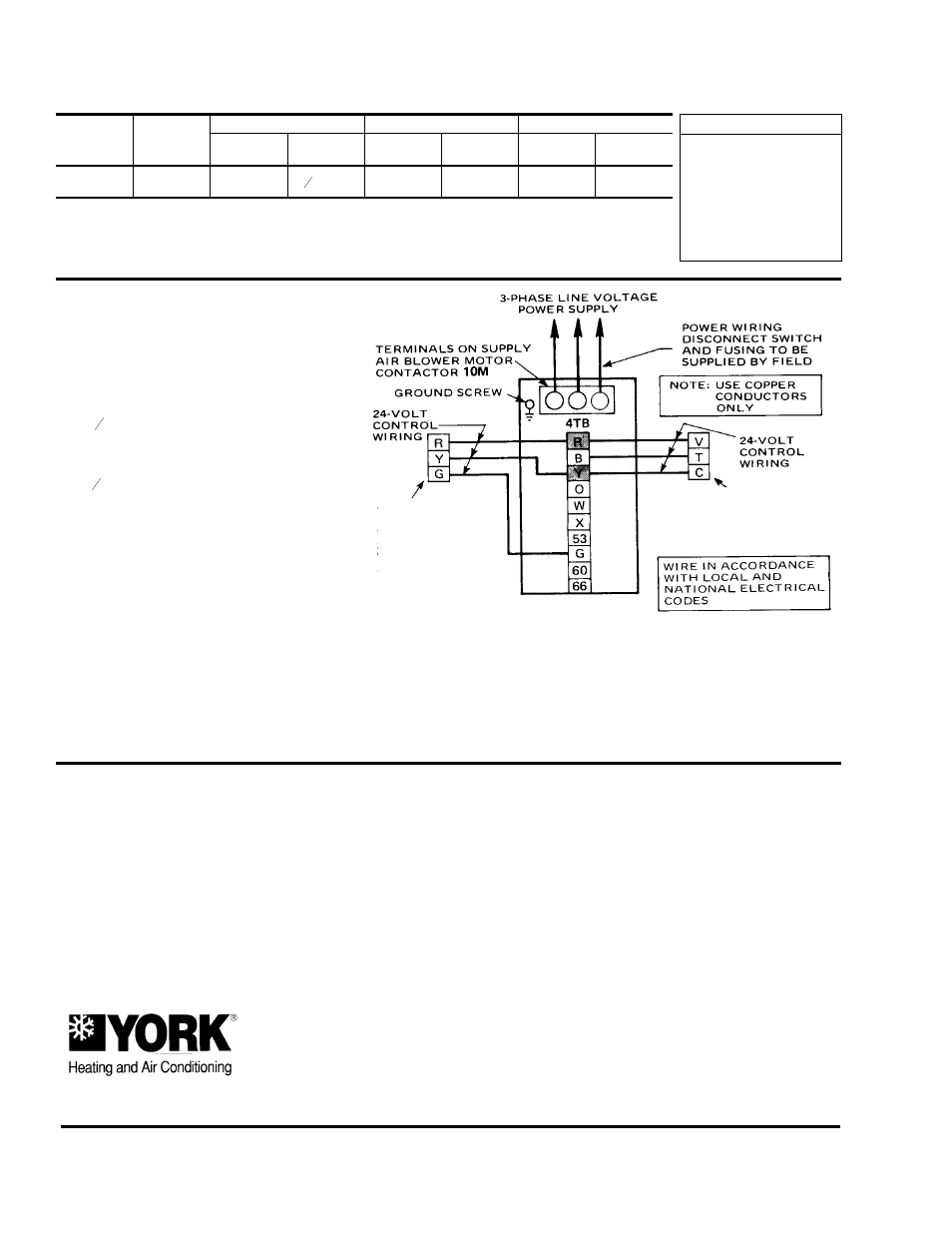

POWER AND CONTROL WIRING

Install electrical wiring in accordance with appli-

cable national, local and municipal codes. The

unit should be grounded in accordance with

these codes.

Route the power wires into the unit through one

of the

%

&

" (22.2mm) dia.knockouts in the panel

with the supply air opening and connect them to

the terminals on blower motor contactor 10M.

Route the control wires into the unit through the

other

%

&

" (22.2mm) dia.knockout and connect

them to the terminals on block 4TB. Refer to

the unit drawing in Figure 7 for the locations of

these knockouts.

If the unit includes an electric heat accessory,

route the power wires into heater control box in-

stead of the unit. Refer to the electric heat in-

structions for additional installation information.

Refer to Table 4 to size the disconnect switch,

the power wiring and the fuses. Refer to Figure

8 for typical field wiring.

NOTE: Three phase motor rotation may be incor-

rect when the unit is first started up. Re-

verse phase (leads L1 and L2) at

contactor to obtain the correct rotation.

FIG 8 - TYPICAL FIELD WIRING (Cooling only)

TERMINALS ON BLOCK 3TB OF

THE BLOWER UNIT

TERMINALS ON

1-STAGE COOLING

THERMOSTAT

2TH0870124

Motor

(HP/kW)

Blower

Range

(RPM)

Adjustable Motor Pulley

Fixed Blower Pulley

Belt

Pitch Dia

(In./mm)

Bore

(In./mm)

Pitch Dia.

(In./mm)

Bore

(In./mm)

Designation

Pitch Lg.

(In./mm)

3 / 2.2

615/800

3.4 - 4.4 / 86

- 112

%

&

/ 22.2

8.0 / 203

1 / 25

A54

55.3 / 1405

TABLE 7 - BLOWER MOTOR AND DRIVE DATA

Subject to change without notice. Printed in U.S.A

Copyright

by York International Corporation

5005

York

Drive

035-12124-000 Rev. A (0501)

Supersedes: 550.39-N5YI (894)

Unitary

Products

Group

Norman

OK

73069