Maintenance – Zenoah BC3500DWM User Manual

Page 16

GB-16

BC3500DLM / BC3500DWM

9. Maintenance

WARNING

• Make sure that the engine has stopped and is cool

before performing any service to the machine.

Contact with moving cutting head or hot muffler

may result in a personal injury.

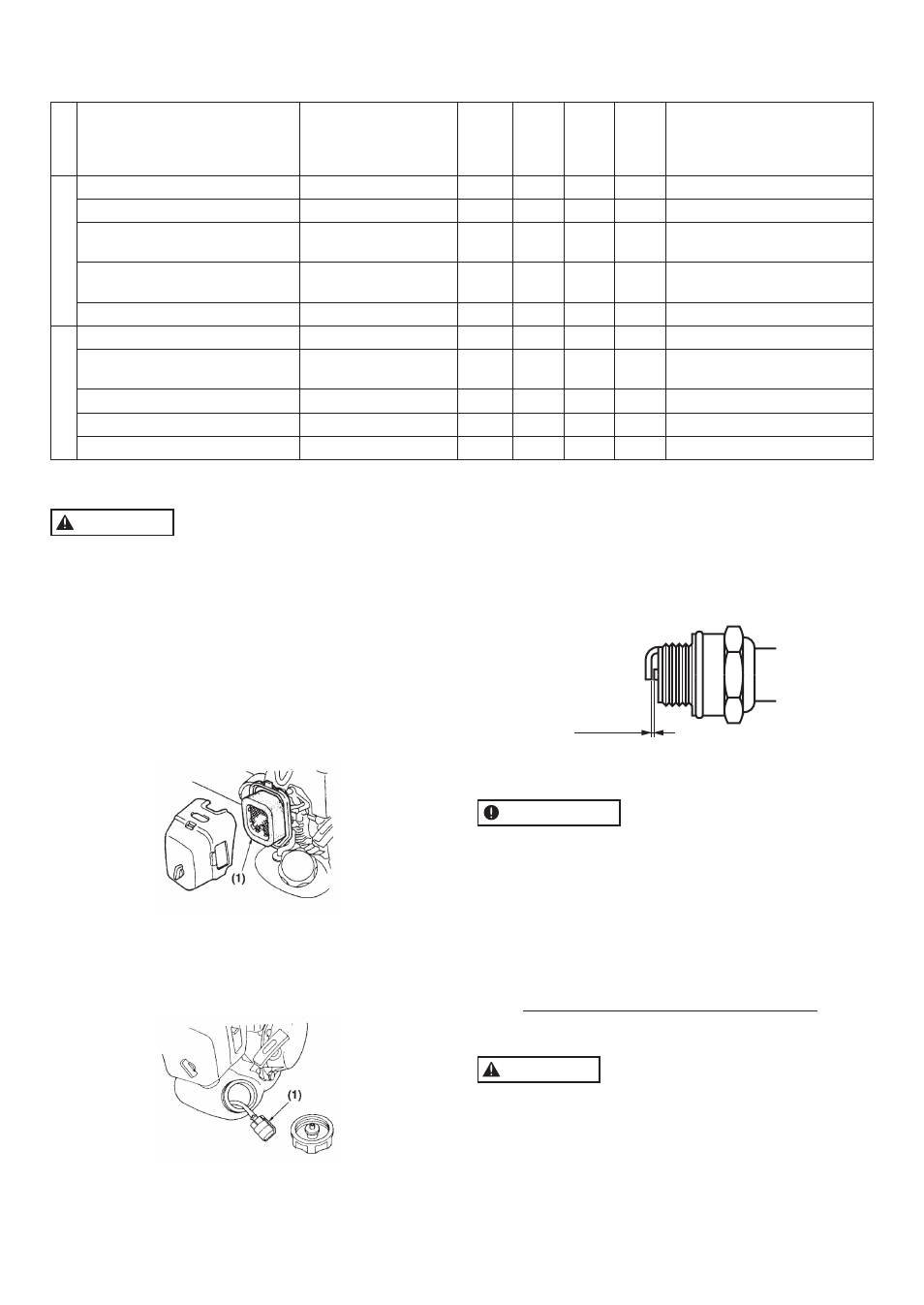

AIR FILTER

• The air filter, if clogged, will reduce the engine per-

formance. Check and clean the filter element in

warm, soapy water as required. Dry completely

before installing. If the element is broken or shrunk,

replace with a new one.

(1) Air filter

FUEL FILTER

• When the engine runs short of fuel supply, check the

fuel cap and the fuel filter for blockage.

(1) Fuel filter

SPARK PLUG

• Starting failure and misfiring are often caused by a

fouled spark plug. Clean the spark plug and check

that the plug gap is in the correct range. For a re-

placement plug, use the correct type specified by

ZENOAH.

0.6 - 0.7 mm

• REPLACEMENT PLUG IS A NGK BPMR7A.

IMPORTANT

• Note that using any spark plug other than those

designated may result in the engine failing to operate

properly or in the engine becoming overheated and

damaged.

• To install the spark plug, first turn the plug until it is

finger tight, then tighten it a quarter turn more with a

socket wrench.

TIGHTENING TORQUE:

14.7 ~ 21.6 N.m.

(150 ~ 220 kg-cm)

MUFFLER

WARNING

• Inspect periodically, the muffler for loose fasten-

ers, any damage or corrosion. If any sign of ex-

haust leakage is found, stop using the machine

and have it repaired immediately in the reperir

specialty store.

• Note that failing to do so may result in the engine

catching on fire.

System/components

Procedure

Before

use

Every

25

hours

after

Every

50

hours

after

Every

100

hours

after

Note

ENGINE

fuel leaks, fuel spillage

wipe out

✔

fuel tank, air filter, fuel filter

inspect/clean

✔

replace, if necessary

idle speed adjuster

see adjusting idling

speed (p. 11)

✔

replace carburetor

if necessary

spark plug

clean and readjust

plug gap

✔

GAP: .025 in (0.6 ~ 0.7 mm)

replace, if necessary

intake air cooling vent

clean

✔

SHAFT

throttle trigger, stop switch

check operation

✔

cutting parts

replace if

something’s wrong

✔

angle transmission

grease

✔

screws/nuts/bolts

tighten/replace

✔

✔

not adjusting screws

cutting attachment guard

make sure to attach

✔