Attaching control cables, Attaching chute assembly, Attaching chute directional control – Yard Machines 611 User Manual

Page 8

8

bolts finger tight. At this point the shift lever and

shift lever spring are not against each other. As you

tighten the bolts and nuts with two wrenches, these

will pull together. See Figure 7.

•

Tighten all hardware assembled to this point. Make

sure that clutch grips are moving freely.

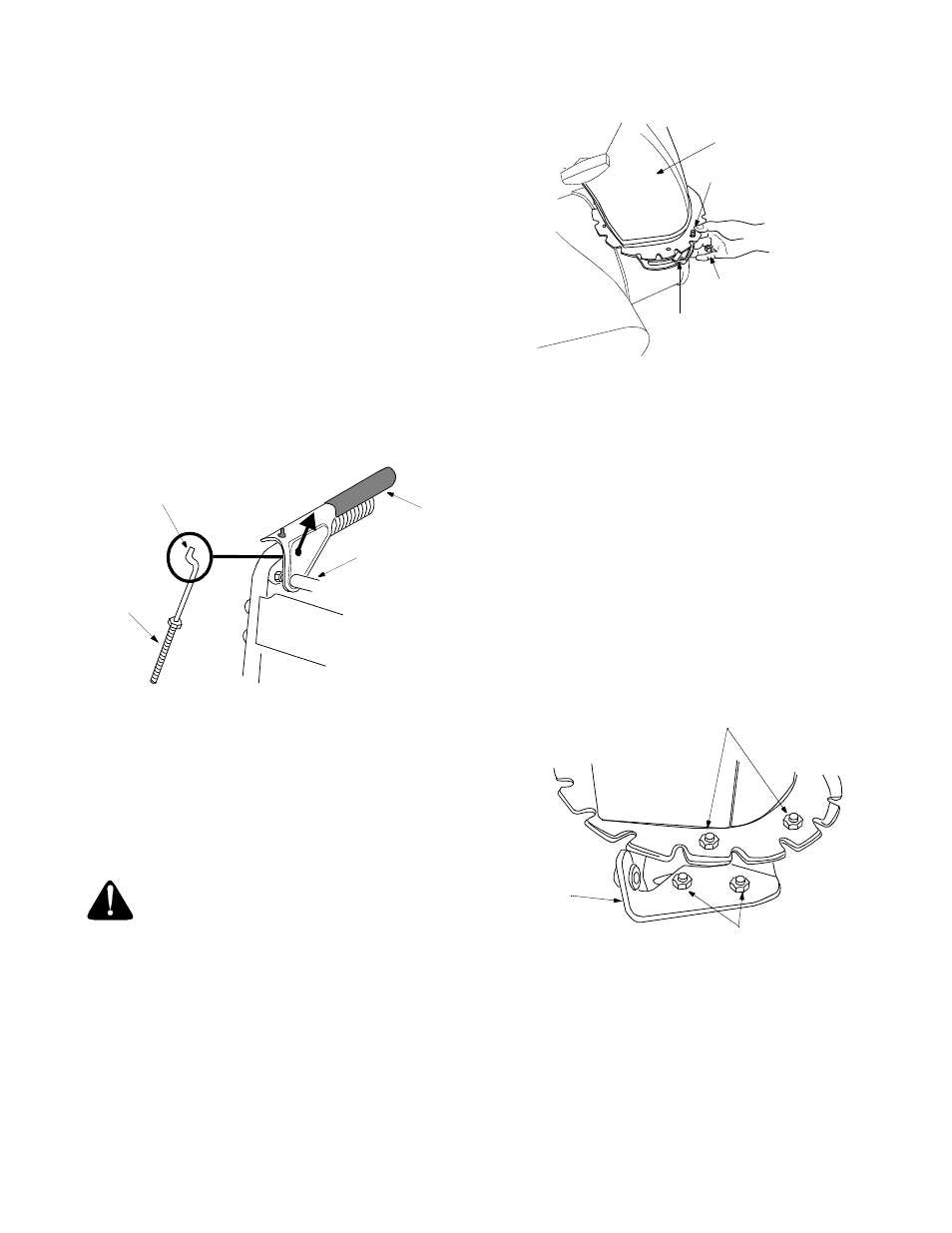

Attaching Control Cables

(Use Hardware E.)

•

Thread hex nuts (J) onto the “Z” fittings (R). Insert

“Z” fitting into hole in clutch grips. See Figure 8.

•

Route the left cable between engine and speed

selector plate and then between handle panel and

clutch lever pivot rod before threading onto the left

“Z” fitting.

•

Assemble the right cable in the same manner.

•

Both cables should have minimal slack, but not

tight. Tighten or loosen hex nuts on the “Z” fitting to

adjust.

Figure 8

IMPORTANT:

If the right hand lock-out cable is not

adjusted correctly, wheels will tend to turn. If the left

hand lock-out cable is not adjusted correctly, the

augers will keep on rotating.

IMPORTANT:

Please note that the drive clutch cable on

units with 16” wheels is routed under the axle. In other

units, the cable is routed over the axle.

WARNING:

Do not over-tighten the clutch

cables. Tension on either cable in the

disengaged (up) position may override the

safety features of the machine.

Attaching Chute Assembly

(Use Hardware Group F.)

•

Place chute assembly over chute opening, with the

opening in the chute assembly facing the front of

the unit.

•

Place chute flange keepers beneath lip of chute

assembly, with the flat side of chute flange keeper

facing downward. See Figure 9.

Figure 9

•

Insert hex bolt (K) up through chute flange keeper

and chute assembly as shown in Figure 9. Secure

with hex lock nut (M). After assembling all three

chute flange keepers, tighten all nuts and bolts

securely. Do not over-tighten.

NOTE: Lock nuts cannot be threaded onto a bolt by

hand. Tighten with two 7/16” or adjustable wrenches.

Attaching Chute Directional Control

(Use Hardware Group G.)

•

Loosen the two hex nuts which secure the lower

chute directional control support bracket (see

Figure 10) to the snow thrower housing.

Figure 10

•

Place one flat washer (T) over the end of the chute

directional control, then insert the end of the chute

directional control into the hole in the plastic

bushing on the chute bracket. See Figure 11. Place

second flat washer (T) on chute directional control,

and secure with hairpin clip (S).

“Z” Fitting R

Hex Nut J

Clutch

Grip

Handle

Panel

Pivot

Rod

Chute

Assembly

Hex Bolt K

Hex Lock Nut M

Chute Flange

Keeper

Hex Bolts K

Hex Lock Nuts M

Lower

Chute

Directional

Control

Bracket

Hex Nuts