Zanussi, Inner cell with rounded corners, Evaporator with antirust protection – Zanussi 110780 User Manual

Page 2: Automatic heated door frame, Stand alone printer as accessory, Pc connection as accessory, gate rs 485

ACTIVE BLAST CHILLERS

10/15/28 kg

DCA01

2011-06-10

The Company reserves the right to alter technical specifications without prior notice.

ZANUSSI

P R O F E S S I O N A L

TROLLEY FOR 10XGN1/1 ROLL IN RACK

922130

TROLLEY FOR 10X1/1 & 2/1 ROLL IN RACK

922128

ROLL-IN RACK SUPPORT BC+BCF 28KG 10GN1/1

881518

RILSAN COATED GRID

881061

881061

881061

PRINTER HACCP BASIC VERS-REF.ELECR.CONTR

881532

881532

881532

PLASTIC COATED GRID-600X400 MM

880864

880864

880864

PAIR OF 1/1 GN AISI 304 S/S GRIDS

921101

921101

921101

KIT TO CONVERT TO 10X1/1 SLIDE-IN RACK

922201

KIT HACCP ADVANCED CONNECT. BC/BCF LW+CW

880183

880183

880183

COOK&CHILL KIT-6 GN OVEN/15KG BL.CHILLER

881528

80 MM PITCH SIDE HANGERS 10X1/1 GAS 0VEN

922116

80 MM PITCH SIDE HANGERS 10X1/1 ELE.OVEN

922115

60 MM PITCH SIDE HANGERS 10X1/1 GAS OVEN

922122

60 MM PITCH SIDE HANGERS 10X1/1 ELE.OVEN

922121

4 WHEELS FOR BLAST CHILLERS

881097

881097

4 FEET FOR UNDERCOUNTER BLAST CHILLER

881493

3-POINT-SENSOR PROBE-BL.C/FREEZERS LW

880212

880212

1 SINGLE-SENSOR PROBE-BL.C/FREEZERS LW

880213

880213

880213

BC10A

110780

BC15A

110717

BC28A

110718

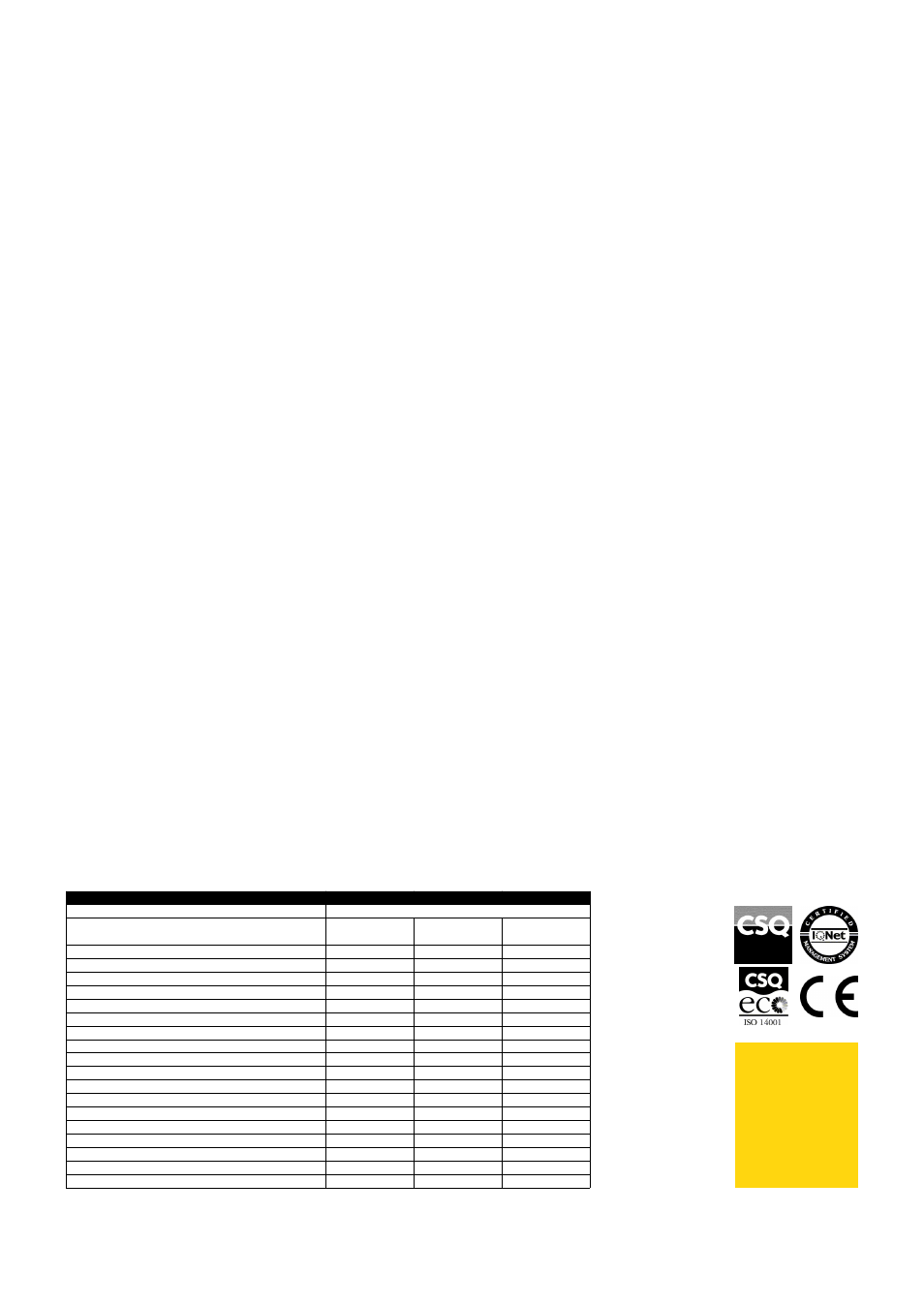

ACCESSORIES

MODELS

OPTIONAL ACCESSORIES

�

The control unit provides several

operating settings: time/core

temperature according to NF and UK

regulations, time/air

temperature/probe personalised

according to national regulations,

sterilizing cycle: UV lamps built-in

(on request), 3 single sensor or

3-sensor temperature probes (as

accessory), ideal for meats,

automatic defrosting and manual

defrosting. All parameters are

programmable.

�

The control unit provides two large

displays to read out: time, core

temperature, residual time, alarms,

service information.

�

Two customizable cycles for each

operating modes, allowing setting

time and air temperature. These two

programs (P1-P2) can be converted

into ice-cream specialist cycles

(shape maintenance and holding).

�

All information related to the

different operating models are

recorded: date, time, cycle, core

temperature, holding temperature,

HACCP accordance.

�

An audible alarm starts when the

cycle ends or terminates abnormally.

�

Chilling times can vary according

to food quantity, density, moisture

contents and type of containers.

�

Internal and external finishing in

304 AISI stainless steel and

backpanel in galvanized steel.

�

HCFC, CFC and HFC free

insulation (Cyclopentane), HCFC

and CFC free refrigerant gas

(R404a).

�

Developed and produced in ISO

9001 and ISO 14001 certified

factory.

�

Inner cell with rounded corners.

�

Door equipped with removable

magnetic gasket with hygienic

design.

�

Evaporator with antirust

protection.

�

Ventilator swinging panel foreasy

access to the evaporator.

�

Automatic heated door frame.

�

Thermostatic expansion valve to

optimize the cooling unit efficiency.

�

Adjustable feet 150 mm high

(except for code 110780).

�

Stand alone printer as accessory.

�

PC connection as accessory, gate

RS 485.

�

No water connections required:

Waste water can be plumbed into

drain, but can also be collected in an

optional waste container.

*NF HYGIENE ALIMENTAIRE

certifying authority: AFAQ AFNOR

CERTIFICATION. Adress:11, Avenue Francis de

Pressense - 93571 Saint-Denis La Plaine Cedex

- France. Conformity with regulation NF031.

Certified guarantees: fitness for cleaning, thermal

performance