Burner specification and data sheet – Weil-McLain WJB1 User Manual

Page 3

Burner Specification and Data Sheet

Light Oil Control Systems:

8.

LF (FALFS): On-off operation, fixed air, reduced fuel low fire start, high fire run. Single-position air, two-position oil.

L (LHO):

On-off operation, low fire start, high fire run. Two-position air, two-position oil.

H (LHL):

Low-high-low-off firing conditions. Two-position air, two-position oil.

M (MOD): On-off operation, with proven low fire start and full modulating firing conditions. Proportional motor drives fuel metering valve and combus-

tion air damper according to the firing conditions. Fixed damper pre-purge on 488-1088R, open damper pre-purge on 1088-1888.

Gas/Light Oil Control Systems:

9.

A/LF (OO/FALFS): Combines gas and light oil characteristics listed above.

L/L (LHO/LHO):

Combines gas and light oil characteristics listed above.

H/H (LHL/LHL):

Combines gas and light oil characteristics listed above.

M/M (MOD/MOD): Combines gas and light oil characteristics listed above.

120/60/1 control circuit is used for all burners.

10.

Control circuit transformer is available as an option.

11.

Motor starter contact will be furnished for all units.

12.

Combustion Controls:

13.

a) R8184G combustion control uses cadmium cell for flame detector to monitor oil burner flame, also furnishes intermittent ignition.

b) RM7897 flame safeguard control uses ultraviolet electronic flame detector to monitor gas or oil burner flame and provides pre-purge programming. “A”

models provide intermittent pilot; “C” models provide interrupted pilot and RUN/TEST switch.

c) RM7840M, E110/EPD390 flame safeguard control monitors the oil or gas burner flame, provides pre-purge and post-purge programming. Timed low fire

start is provided by means of timing built into control. Control is used with UL on-off (low fire start) systems. Ultraviolet sensitive electronic flame detector

is standard with infrared detector available.

d)

RM7840L, E110/EPD170 flame safeguard control monitors the oil or gas burner flame, provides pre-purge and post-purge programming, provides switch-

ing necessary to allow firing rate motor to be driven to both low fire and high fire positions, prevents start-up if pre-ignition interlocks are open and has low

fire start proving circuit. In the event pre-ignition interlock circuit or running interlock circuit does not “prove”, system will lock out on safety. Ultraviolet

sensitive electronic flame detector is standard with infrared detector available.

Gas Control Systems:

7.

A (OO):

On-off operation, low fire start, high fire run. Single-position air, adjustable opening gas valve.

L (LFS):

On-off operation, low fire start, high fire run. Two-position air controlled by damper arm on motorized gas valve.

H (LHL):

Low-high-low-off firing conditions. Two-position air controlled by damper arm on motorized gas valve.

M (MOD):

On-off operation, with proven low fire start and full modulating firing conditions with combustion air control.

Proportional motor drives fuel metering valve and combustion air damper according to the firing conditions.

Fixed damper pre-purge on 488-988R, open damper pre-purge on 988-1888.

Part Number 550-142-022/0509

3

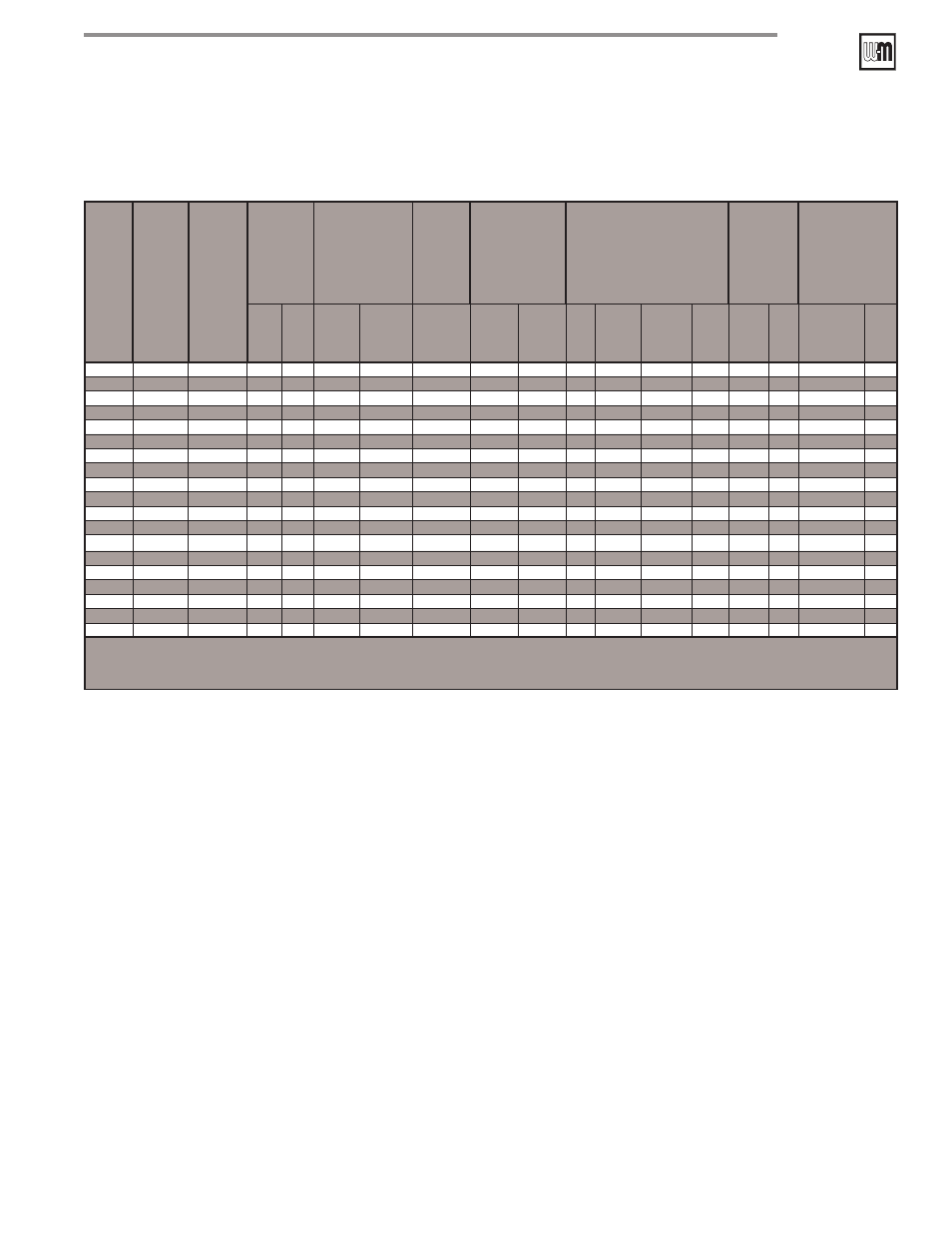

Boiler

Model

Number

Pressure

drop thru

gas train

Inches

W.C.

Gas

orifice

pressure

Inches

W.C.

Gas

Pressure

required at

Gas Control

Inlet

Inches

W.C.

Initial Damper

Setting Inches

(Oil)

Initial

Damper

Setting

Inches

(Gas)

Initial Damper

Setting Inches

(Gas/Light Oil)

Oil Nozzle(s)

Oil

Pressure

PSIG

Fuel Unit

Burner-Motor

Driven

3450 RPM

Min. Max. Low

Fire High Fire High Fire

High

Fire

(Gas)

High

Fire

(Oil)

Qty.

GPH @

100

PSIG

Brand Spray

Angle

High

Fire

Low

Fire

Type

Gear

GPH

488R

2.3

2.4

5.5

14

1/4

1

1-1/4

1-5/16

1

1

4.00

Hago P

45º

300

100

22R220D

45

488

2.3

2.5

5.7

14

1/4

1-13/16

1-7/16

1-9/16

1-3/16

1

4.00

Hago P

45º

305

100

22R220D

45

588

3.7

2.8

7.0

28

1/2

13/16

1-7/8

1-7/8

1-3/16

1

5.50

Hago P

45º

290

100

22R220D

45

688

2.7

3.2

6.2

28

7/16

7/8

1-3/16

1-5/16

1

1

7.00

Hago P

45º

290

100

22R220D

45

788

2.9

2.8

5.1

28

1/2

1-3/8

1-13/16

1-7/8

1-1/2

2

4.25

Hago P

60º

280

100

22R221D

70

888

2.55

1.8

4.5

28

5/8

1-1/2

1

1-3/4

1-1/2

1

10.00

Hago P

45º

280

100

22R221D

70

988R

3.15

1.7

4.9

28

5/8

1-3/4

1-1/8

1-7/8

1-3/4

1

10.00

Hago P

45º

300

100

22R221D

70

988

3.8

1.8

5.8

28

1-3/16

1-5/16

1-1/4

1-1/2

1-3/16

1

11.00

Hago P

45º

290

100

22R221D

70

1088R

4.4

2.2

6.6

28

5/8

1-1/8

1-3/8

1-1/4

1-1/8

2

6.00

Hago P

45º

280

100

22R221D

70

1088

3.2

2.4

6.0

28

3/4

1-5/16

1-7/16

1-7/16

1-5/16

2

6.50

Hago P

45º

280

100

22R221D

70

1188

4.0

2.0

6.4

28

3/4

1-3/4

1-13/16

1-7/8

1-3/4

2

7.00

Hago P

45º

280

100

22R221D

70

1288

3.0

2.4

6.0

28

13/16

2-1/16

2-5/16

2-5/8

2-1/8

2

7.50

Hago P

45º

300

100

22R221D

70

1388

3.8

2.0

6.3

28

3/4

1-1/2

2-1/2

2-1/2

1 7/8

2

8.50

Hago P

60º

290

100

22R322D

105

1488

4.6

2.6

7.7

28

15/16

2-3/16

2-1/8

2-1/4

2

2

9.00

Hago P

60º

300

100

22R322D

105

1588

5.1

2.8

8.7

28

1

2-1/8

3-3/8

3-1/4

2-1/4

2

10.00

Hago P

60º

280

100

22R322D

105

1688R

4.6

2.9

9.2

28

1 1/16

2-1/2

1-7/8

2-1/4

1-1/2

2

10.00

Hago P

60º

300

100

22R623D

135

1688

6.1

3.1

9.8

28

1

2-5/8

2-1/4

2-1/2

2-1/8

2

10.50

Hago P

60º

295

100

22R623D

135

1788

5.25

4.5

9.1

28

9/16

2-1/4

3-1/4

3-1/4

3

2

11.00

Hago P

60º

300

100

22R623D

135

1888

5.7

6.0

10.4

28

1

3

1-3/4

1-7/8

1-7/8

3

8.0

Delevan

60º

300

65

SG0550

108

Standard Oil Pump Location:

488R through 1488 Gas / Oil – Integral to Burner, 1588 through 1888 Remote Pump

488R through 1688 Oil – Integral to Burner, 1788 and 1888 Remote Pump