Connect steam piping, Optional reservoir piping – Weil-McLain 550-141-829/1201 User Manual

Page 17

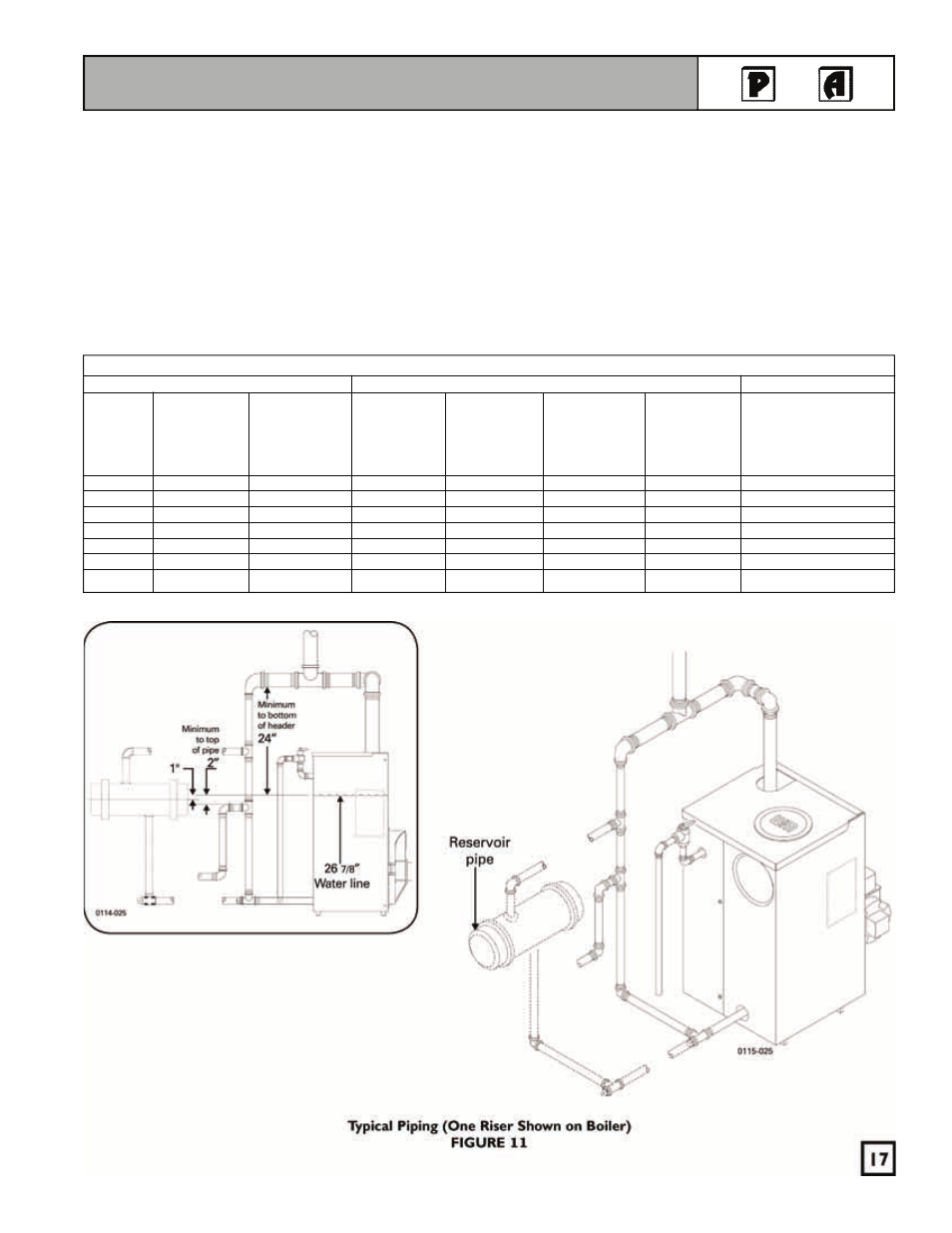

Optional reservoir piping:

Modern steam boilers are designed to steam for

less time than older, larger boilers. When replacing

an older steam boiler, the system condensate

return time may be longer than the steaming time.

This can cause the following problems:

•

Boilers fitted with an automatic water feed

could overfill.

•

Units fitted with only a low water cutoff would

shut down and cycle while waiting for

condensate to return.

To size and install reservoir piping, see FIGURE 11

and Bulletin AE-8403 (available through your

Weil-McLain distributor or sales office):

1. Pipe boiler as shown on pages 14 through 16.

2. Use 8" diameter reservoir pipe.

3. Locate centerline of reservoir pipe 1" below

26

7

/

8

" boiler waterline.

Connect Steam Piping

CONTINUED

CONDENSATE RECEIVER CAPACITY TABLE

MINIMUM CONDENSATE RECEIVER CAPACITY – GAL.

RECOMMENDED

I=B=R GROSS

CONDENSATE

OUTPUT

GALLONS

15 MIN.*

30 MIN.*

45 MIN.*

60 MIN.*

FEED PUMPING RATE

BOILER

LBS STEAM

CONDENSATE

BOILER

BOILER

BOILER

BOILER

GPM

MODEL

PER HOUR

PER HOUR

OPERATION

OPERATION

OPERATION

OPERATION

AT 15 PSI

SGO-3

114

14

4

8

12

16

0.5

SGO-4

150

18

5

11

16

22

0.6

SGO-5

180

22

6

13

19

26

0.7

SGO-6

216

26

8

16

23

31

0.9

SGO-7

246

30

9

18

27

35

1.0

SGO-8

274

33

10

20

30

39

1.1

SGO-9

303

36

11

22

33

44

1.2

* Maximum time to when condensate returns to boiler.