Gas piping – Weil-McLain LGB-5 User Manual

Page 3

LGB

LGB

LGB

LGB

LGB-4

-4

-4

-4

-4 & 5

5

5

5

5

•

Control Supplement

•

UCS

•

Propane

3

Part Number 550-141-919/0304

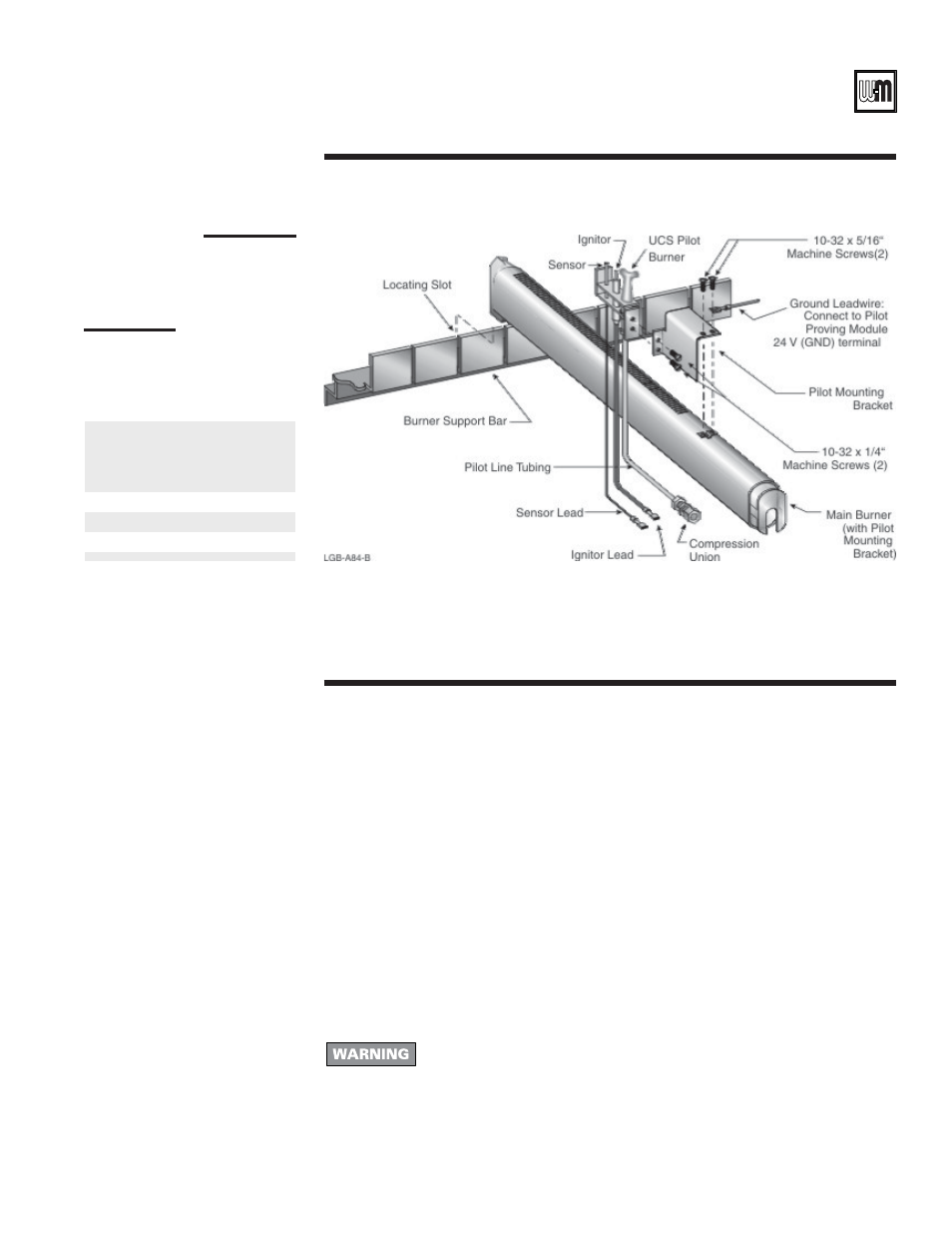

Figure 1

Pilot burner

assembly

Table 1

Pilot and

flame sensor

locations

1. Contact gas supplier to size pipes, tanks and regulator.

a. Inlet gas pressure to manual main shut-off gas valve minimum 11" W.C., maximum

13" W.C.

b. If pressure to gas valve exceeds 13" W.C., install 100% lock-up gas pressure regulator

upstream of hand valve.

2. Remove knockout disc from jacket panel side to which gas supply will be piped.

3. Follow good piping practices.

4. Pipe joint compound (pipe dope) must be resistant to corrosive action of liquefied petroleum

gases. Apply sparingly only to male threads of pipe joints.

5. Install drip leg at inlet of gas connection to boiler. Where local code/utility requires, extend

drip leg to floor.

6. Install ground joint union when required for servicing.

7. Support piping by hangers, not by boiler or its accessories.

8. Purge all air from supply piping.

9. Before operating boiler, check boiler and its gas connections for leaks.

Boiler

model

Electronic

pilot

burner *

Standing

pilot

burner *

Propane

carton

LGB-4

4

2

4 and 5

LGB-5

5

2

4 and 5

* Burner position, counting from left to right

III

Gas piping

Do not check for gas leaks with an open flame - use bubble test. Failure to

use bubble test or check for leaks can cause severe personal injury, death or

substantial property damage.

a. Close manual main shut-off valve during any pressure testing greater than 13" W.C.

b. Disconnect boiler and gas valve from gas supply piping during any pressure test

greater than 13" W.C.

10. In Canada - manual main shut-off valve must be identified by installer.