Connect steam boiler piping – Weil-McLain 78 User Manual

Page 15

• Installation • Start-Up • Maintenance • Parts

Connect Steam Boiler Piping

6a

General steam piping information:

•

Hartford Loop piping arrangement and wet

return are required for steam boilers.

• Maintain 24-inch minimum from waterline to

bottom of header (56-1/4" from bottom of

section).

• When using condensate receiver, feed pump

must be energized by boiler-mounted pump

controller.

Install piping:

Install piping as shown on page 16 for single

boilers, page 18 for multiple boilers.

Improperly piped systems or

undersized piping can contribute

to erratic boiler operation and

possible boiler or system

damage. Piping system must be

installed as shown, using pipe

sizes shown. Consult local Weil-

McLain distributor or sales office

before installing alternate piping.

1. Connect supply and return piping:

a. See table below and:

1) Size forced condensate return piping by

pump.

2) Size gravity condensate return same as

equalizer “J” pipe size.

b. Install system drain valve in lowest part of

return piping close to boiler. ASME size

requirements are shown in Table, page 13.

c. Connect cold water fill piping as shown in

Figure 14. Also shown are recommended

valves and water meter, if used. Water meter

will detect added makeup water, indicating

leaks in system.

Part No. 550-141-705

15

* Based on ASHRAE Handbook recommendations, allowing 1/2 oz. pressure drop per 100 feet of pipe for dry return.

**Based on ASHRAE Handbook recommendations, allowing 2 oz. pressure drop per 100 feet of pipe at 3.5 PSIG.

Maintain minimum 24" height from waterline to header.

Steam Boiler Pipe Size Table

Based on 2-Pipe Steam System

*Riser

* *

Pipe Size - In.

H

J

Fig.

Boiler

Header

Equalizer

No.

Model

A

B

C

In.

In.

15

378

3

3

2

15 478

4

4

2

15 578

4

4

2-1/2

16 678

3

3

4

2-1/2

16 778

4

4

4

2-1/2

16 878

4

4

4

3

16 978

4

4

6

3

17 1078-1278

4

4

4

6

3

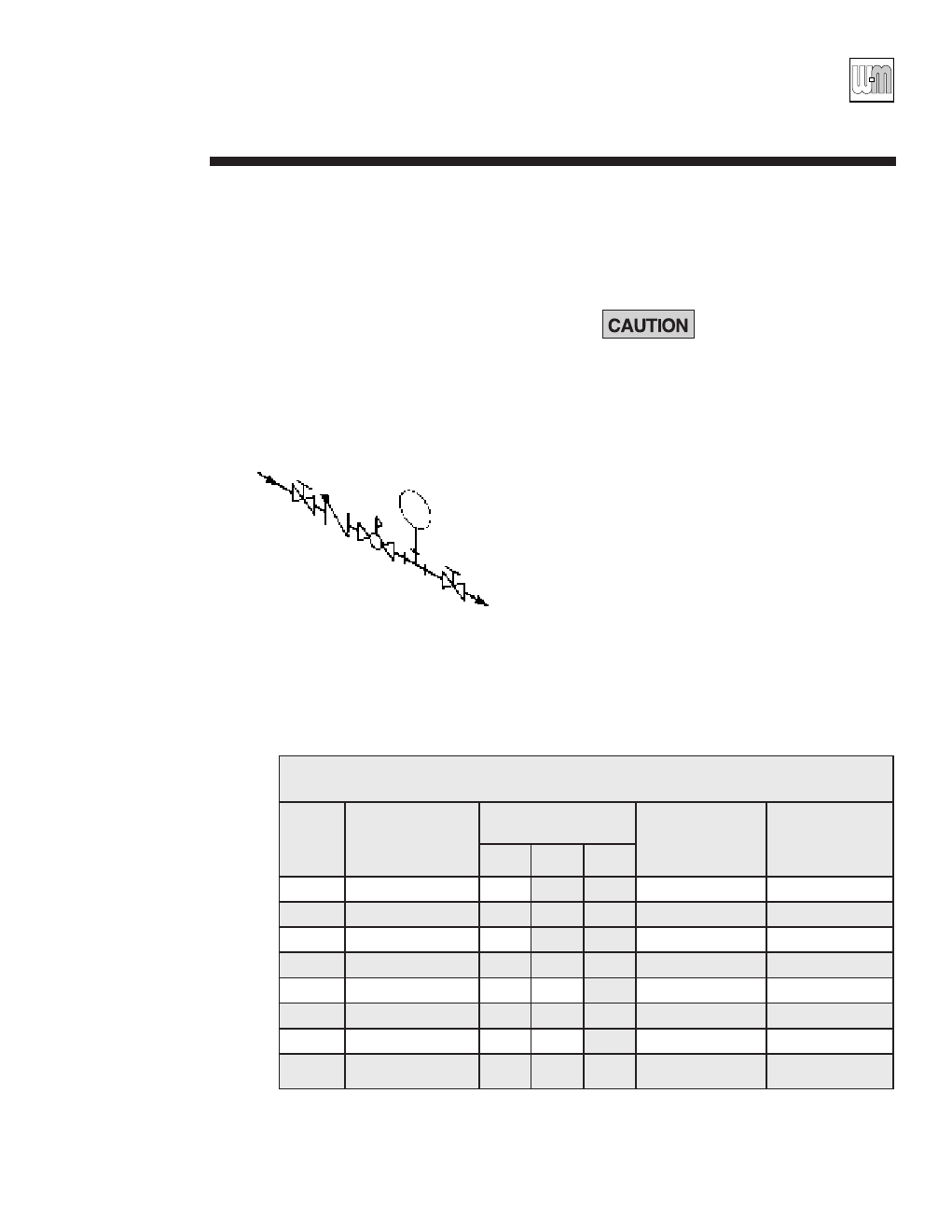

Cold

water fill

Manual

isolation

valve

Pressure

reducing valve

(when used)

Manual

isolation

valve

Water meter

Check

valve

To condensate

return piping or

condensate

receiver

(see fig. 18,

page 17)

Figure 14 Cold Water Fill Piping