Warning, 540 rpm speed range only, Always obey all safety warnings – Worksaver SDM40-60 User Manual

Page 17

23

16

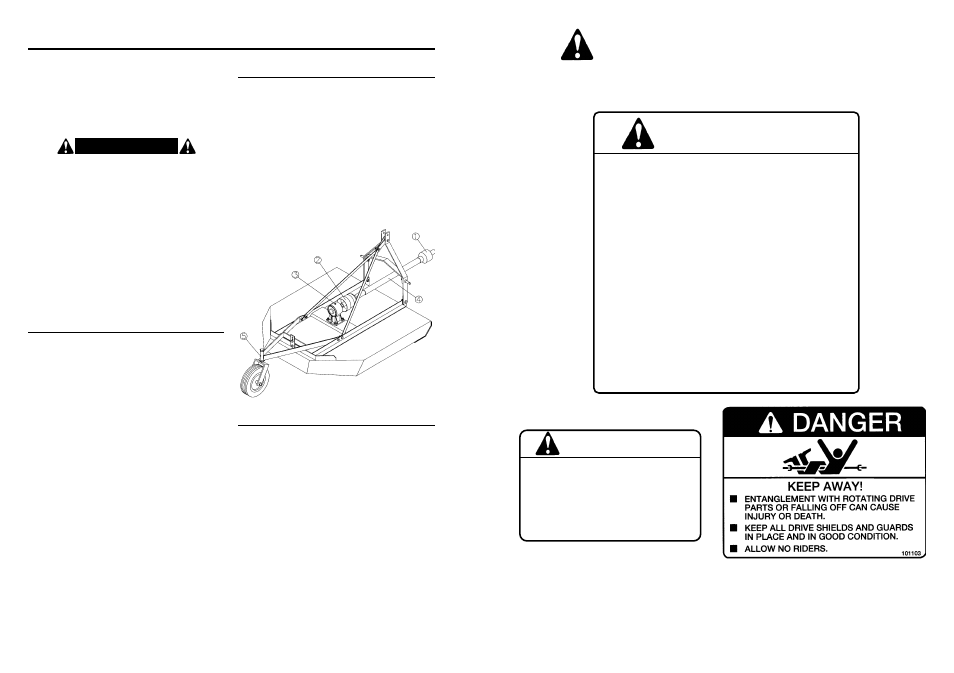

The types of Safety Sign and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular function

related to that area, that requires your SAFETY AWARENESS.

REMEMBER: If Safety Signs have been damaged, removed, become illegible or parts replaced without Signs, new

Safety Signs must be applied. New Safety Signs are available from your authorized distributor or factory.

S A F E T Y S I G N L O C ATIONS

(continued)

WARNING

540 RPM SPEED

RANGE ONLY

HIGHER PTO SPEEDS CAN CAUSE

PERSONAL INJURY AND

EQUIPMENT FAILURE

101101

WARNING

To prevent serious injury or death:

Si no lee ingles, pida ayuda a alguien que si lo lea para

que le traduzca las medidas de seguridad.

• Read and understand Operator’s Manual before using.

Review annually.

• Do not permit riders on the tractor or cutter. Never

carry children on tractor seat.

• Do not allow children to operate cutter.

• Operate only with guards installed and in good condition.

• Keep away from moving parts.

• Operate only with tractor equipped with ROPS and

seatbelts.

• Before mowing, clear debris from mowing area.

• Do not operate in the raised position.

• Stop engine, set brake and wait for all moving parts to

stop before dismounting.

• Support cutter securely before working beneath unit.

• Transport with clean reflectors, SMV and working lights

as required by federal, state, and local laws.

M100

O W N E R S E RV I C E

The information in this section is written for operators

who possess basic mechanical skills. Should you need

help, your dealer has trained service technicians

available. For your protection, read and follow all safety

information in this manual.

W A R N I N G !

▲

Lower cutter to ground or block securely, turn

tractor engine off, remove key and disconnect

cutter driveline from tractor PTO before perform-

ing any service or maintenance.

▲

Before working underneath, raise 3-pt. hitch to

highest position and block cutter securely.

Hydraulic system leakdown and failure of

mechanical or hydraulic system can cause equip-

ment to drop.

▲

Keep all persons away from operator control area

while performing adjustments, service or mainte-

nance.

L U B R I C AT I O N I N F O R M AT I O N

Figure 6 shows the lubrication points. The accompany-

ing chart gives the frequency of lubrication in operating

hours, based on normal conditions. Severe or unusual

conditions may require more frequent lubrication.

Do not let excess grease collect on or around parts,

particularly when operating in sandy areas.

Use an SAE 90W gear lube in gearbox.

Use a lithium grease of NO. 2 consistency with a MOLY

(molybdenum disulfide) additive for all locations. Be sure

to clean fittings thoroughly before attaching grease gun.

When applied according to the lubrication chart, one

good pump of most guns is sufficient. Do not over

grease.

Figure 6.

LUBRICATION CHART

REF NO.

DESCRIPTION

FREQUENCY

1

Front U-Joint

8 Hrs.

2

Rear U-Joint

8 Hrs.

3

Gearbox – Fill to proper level

Check Daily

4

Slip Joint

8 Hrs.

5

Tailwheel

8 Hrs.

Daily lubrication of the PTO slip joint is necessary.

Failure to maintain proper lubrication can result in

damage to U-joints, gearbox, tractor PTO and/or cutter

driveline.

ALWAYS OBEY ALL

SAFETY WARNINGS!!

R O U T I N E M A I N T E N A N C E

DAILY CHECKS:

1. Check that all bolts, nuts, and screws are tight.

Checking the bolts and nuts on the blade beam

assembly is particularly important.

2. Check daily the level of the gearbox oil and top up to

the correct level. Check for gearbox oil leaks. It should

be noted that no warranty claim can be submitted on

a gearbox that has run dry. It is essential that the

gearbox is kept correctly filled with gearbox oil.

3. Grease the PTO shaft daily.

4. Check the wear on the blades. Sharpen them

routinely with an angle grinder or replace when worn

down too far. You should keep at least two sets of

blades, bolts, and nuts as spares for your cutter.

AT THE END OF YOUR CUTTING SEASON:

1. Drain and change the oil in your gearbox.

2. Check and replace, where necessary, blades, bolts,

nuts, or bushings, on the machine.

3. Clean machine and touch up any rust spots that may

have appeared.

4. Replace any safety signs if damaged.

5. Store cutter in clean, dry location.