Principle of operation, Installation, Duct layout – White Rodgers DAMPER MOTOR 2061 User Manual

Page 2: Installing damper motor

2

Point “X”

(locate exactly

opposite

1

⁄

2

” hole)

Centerlines

of Duct

1

⁄

2

” Dia. Hole

#10 Sheet

Metal Screws

Bearing

Plate

15

⁄

16

”

1

3

2

2

4

110-280 or

120-280

Thermostat

2061 Two-Wire

Damper Motor

INTERNAL WIRING

EXTERNAL WIRING

Side “A” of

Motor Switch

Side “B” of

Motor Switch

Warp Switch

Heater

Warp Switch

Contacts

(Normally Closed)

Motor

Contact

“C”

Transformer

Line

To auxiliary circuit

for operating oil

burner or gas valve

NOTE: If same

transformer powers both

the auxiliary circuit and the

damper motor, connect

the auxiliary circuit to

terminals 1 and 3 instead

of 2 and 3.

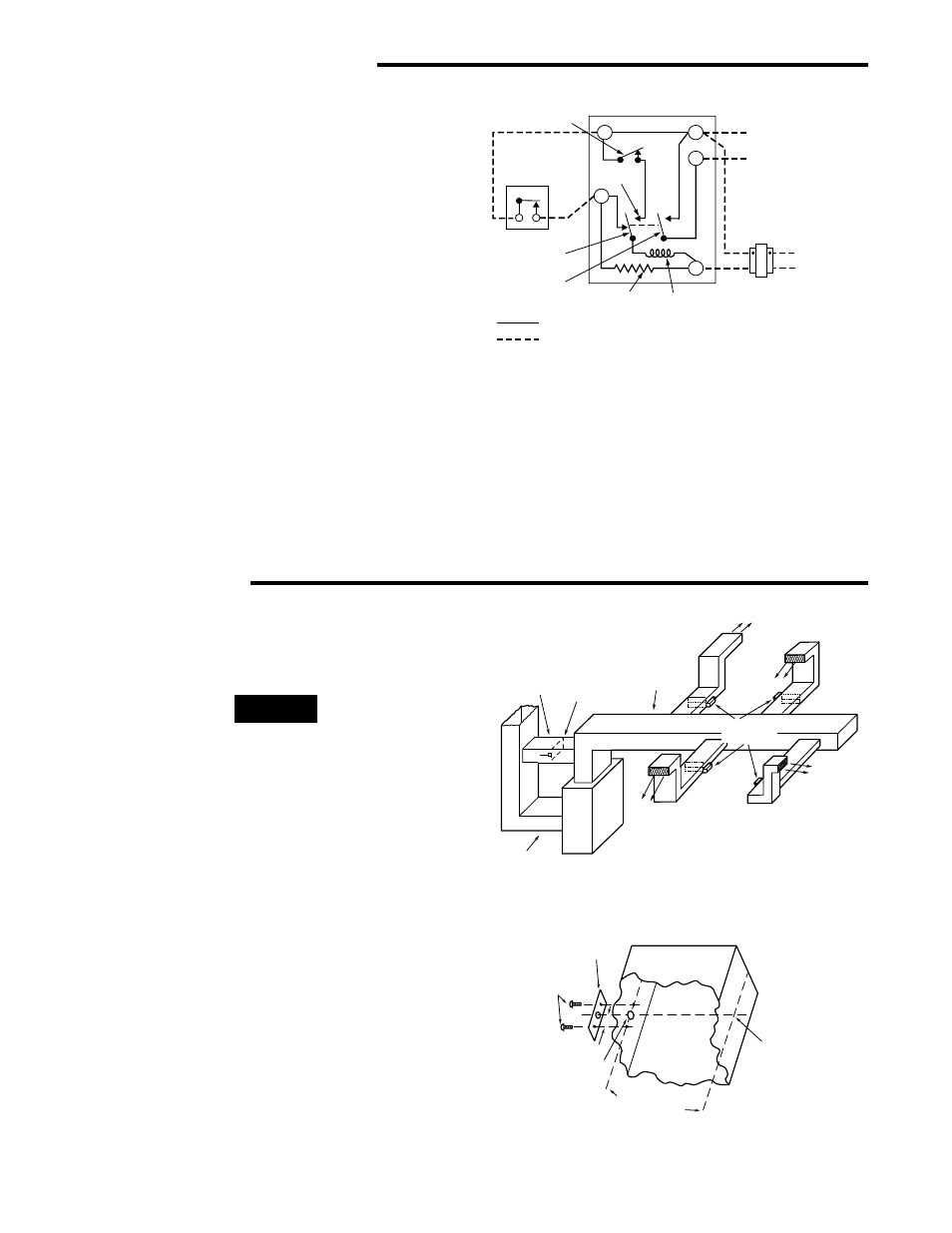

PRINCIPLE OF OPERATION

This schematic shows the damper motor in the closed

position. As the thermostat calls for heat, the damper

motor is energized as a circuit is made through side “A” of

motor switch. (At the same, time a circuit is made through

the warp switch heater.) The damper motor begins to

open.

Before the damper motor reaches the full open position,

side “B” of motor switch closes (providing a low voltage

auxiliary circuit for starting oil burner or opening gas

valve), side “A” of motor switch makes with contact “C”,

and the warp switch heater opens the warp switch con-

tacts. The warp switch heater remains energized and

keeps the warp switch contacts open as long as the

thermostat calls for heat.

When the thermostat is satisfied, the circuit through the

warp switch is broken. After this heater cools for a short

time, the warp switch contacts close, energizing the

damper motor through side “A” of motor switch. Just after

the damper motor begins closing, side “B” of motor switch

opens (breaking the auxiliary circuit), while side “A” of

motor switch makes with contact 4 just before the damper

motor fully closes.

The damper motor draws no current while in the closed

position.

The system is so wired so that if any one zone still calls for

heat, the burner stays on. When all thermostats are

satisfied, all dampers will have closed, and the circuit

broken to the gas valve or oil burner control.

The blower in the furnace operates as in any conven-

tional, unzoned hot air system. When the air in the plenum

is warmed to a set temperature, the fan control turns the

blower on. When the air temperature drops, the fan

control turns the blower off. The addition of zoning has not

affected normal fan operation.

INSTALLATION

DUCT LAYOUT

This illustration shows a typical layout for a zoned warm

air system using Zone-Air Controls.

The use of a bypass damper is recommended. See

page 6 for details.

INSTALLING DAMPER MOTOR

The following instructions apply for 6, 8, and 10” ducts.

(For round ducts and rectangular ducts under 6” a special

bracket is available which replaces the access-mounting

plate.)

1. Select a convenient position for damper motor instal-

lation on duct work to each zone. Carefully locate and

mark center line on each side of duct.

2. Mark location for

1

⁄

2

” hole. Also mark locations for holes

to attach bearing plate by measuring

15

⁄

16

” from center

of

1

⁄

2

” hole. Drill all three holes and attach bearing plate

with two #10 sheet metal screws provided.

3. Locate point “X” on center line exactly opposite

1

⁄

2

”

hole.

NOTE

Bypass Duct

Return Duct

Outlet

Zone 3

Outlet Zone 1

Outlet

Zone 2

Outlet

Zone 4

Supply Duct

DAMPER

MOTORS

Zone 1

Zone 2

Zone 3

Zone 4

BypassDamper

Parts Group

133-0010

Duct Layout For

4 Zone Warm Air System