Installing the gas cooker – Westinghouse GEK1385W User Manual

Page 24

24

INSTALLING

SAFETY WARNINGS ABOUT INSTALLATION

WARNING

• The cooker MUST be installed and serviced by

a qualified technician.

• A Certificate of Compliance MUST be supplied

to be kept by the customer.

• The packing materials MUST be removed before

you install the cooker.

• You MUST follow the installation instructions in this booklet.

• The surrounding kitchen cabinets MUST be able to

withstand 85°C. Electrolux Products WILL NOT accept

responsibility for damage caused by installation into

kitchen cabinets which cannot withstand 85°C.

• The appliance MUST be installed using the flexible

hose supplied.

• The vents, openings and air spaces MUST NOT

be blocked.

• You MUST NOT pull the cooker by the door handles

or the splashback.

• The cooker MUST be checked every five years.

• The cooker MUST NOT be used as a space heater.

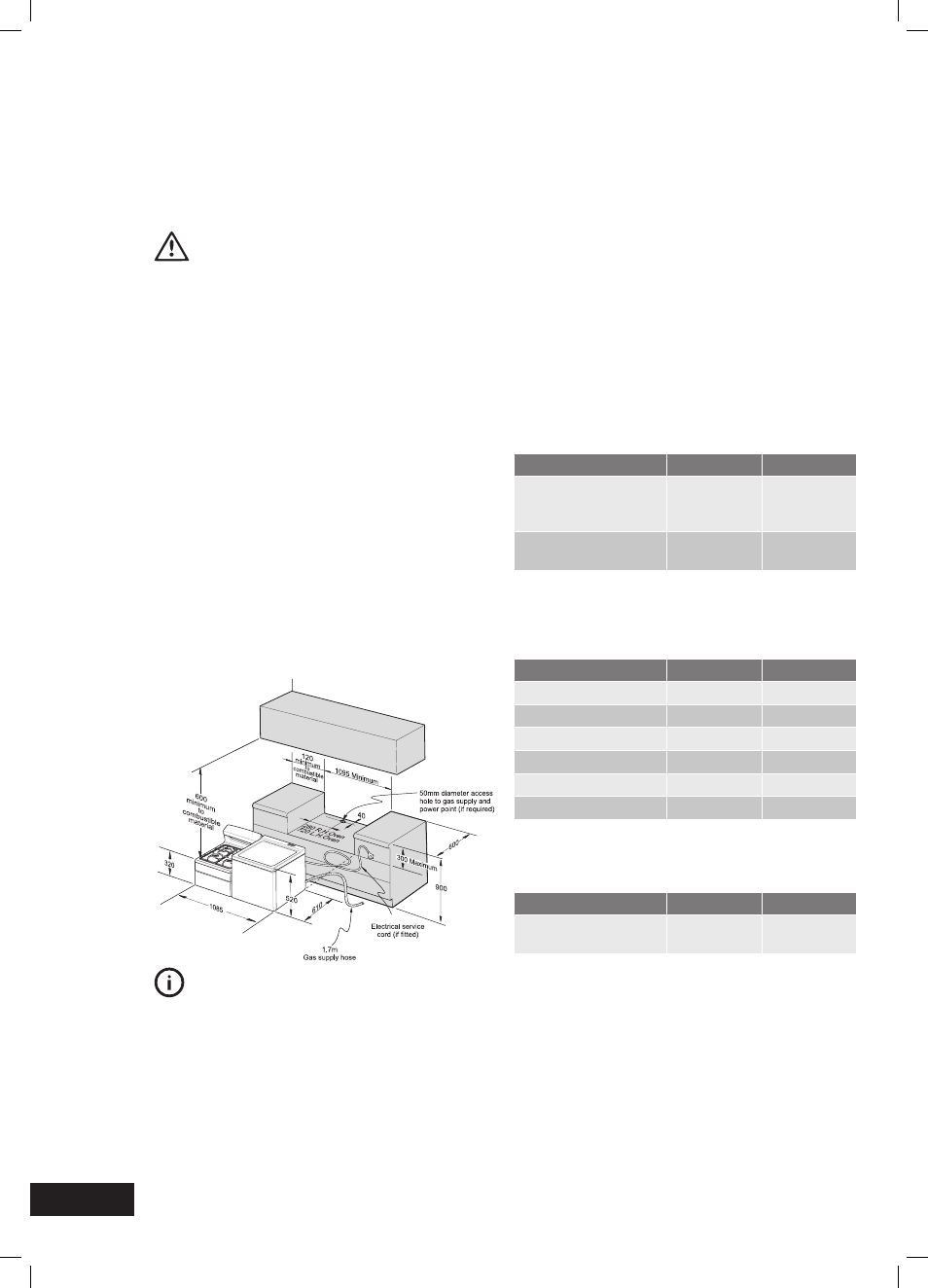

Locating the cooker

Study the diagrams below to be sure of the dimensions

required to locate the cooker safely.

Note: Make sure that the top of the hotplate surface is

at least 10 mm higher than the level of the benchtops.

P

TIPS & INFORMATION

Before you cook in your new oven it is important that

the protective oils used in the manufacture of the product

be removed.

• Make sure that the room is well ventilated (to allow

smoke to escape).

• Run the grill on high for 15 minutes with 10mm

of water in the bottom of the grill dish.

• Then run the oven on 180°C for 2 hours.

Checking gas pressures

The cooker MUST be installed in compliance with:

• The Installation Code for Gas Burning Appliances

and Equipment – AS 5601/AG 601 – issued by

Standards Australia (Particular reference to sections

4.8 & 5.12.1).

• Local gas fitting regulations, municipal building codes

and other statutory regulations.

The cookers come in two gas types: Natural gas and Propane.

Before installation check that the cooker is suitable for the

gas supply. To do this check the gas type on the carton sticker

or on the data plate behind the bottom of the oven door.

The following table shows the supply and operating

pressures for various gas supplies.

GAS TYPE

NATURAL GAS

PROPANE

Supply Pressure

at inlet to appliance

regulator (if fitted)

1.13 (kPa)

Minimum

2.75* (kPa)

Operating Pressure

at appliance test point

1.00 (kPa)

2.75 (kPa)

* If the regulator is placed upstream of the cooker inlet, as is

normal for cookers operating on Propane, then the supply

pressure and operating pressure are the same.

The following table shows the injector sizes for each burner.

INJECTOR ORIFICE

NATURAL GAS

PROPANE

Low Heat Burner

1.00 mm

0.62 mm

Medium Heat Burner

1.35 mm

0.82 mm

High Heat Burner

1.60 mm

0.95 mm

Grill – main injector

1.50 mm

0.82 mm

Oven – main injector

1.60 mm

0.95 mm

Oven – bypass screw

0.73 mm

0.45 mm

Checking pipe size

To work out a suitable pipe size for connection use the

information in the table below.

GAS TYPE

NATURAL GAS

PROPANE

Hourly gas consumption

for this cooker

57.2 MJ/h

56.5 MJ/h

• Information about the length of the run, number of

elbows, tees and bends, the available service pressure

and the supply requirements.

NOTE: The Code AS 5601/AG 601 will help you with

this matter.

INSTALLING THE GAS COOKER

WMAN_540 Upright_Jun11.indd 24

28/06/11 12:07 PM