Sharpening or replacing chipper blades, Changing the friction wheel rubber – White Outdoor Yard Boss 950 User Manual

Page 12

12

NOTE: Be certain to reassemble the flail screen with

the curved side down.

•

Reattach the discharge chute assembly with the

hardware previously removed and connect the bag

to unit.

Sharpening Or Replacing Chipper Blades

NOTE: When tipping the unit, empty the fuel tank and

keep spark plug side up.

•

Disconnect the spark plug wire and ground it

against the engine.

•

Remove the flail screen as instructed in the

previous section.

•

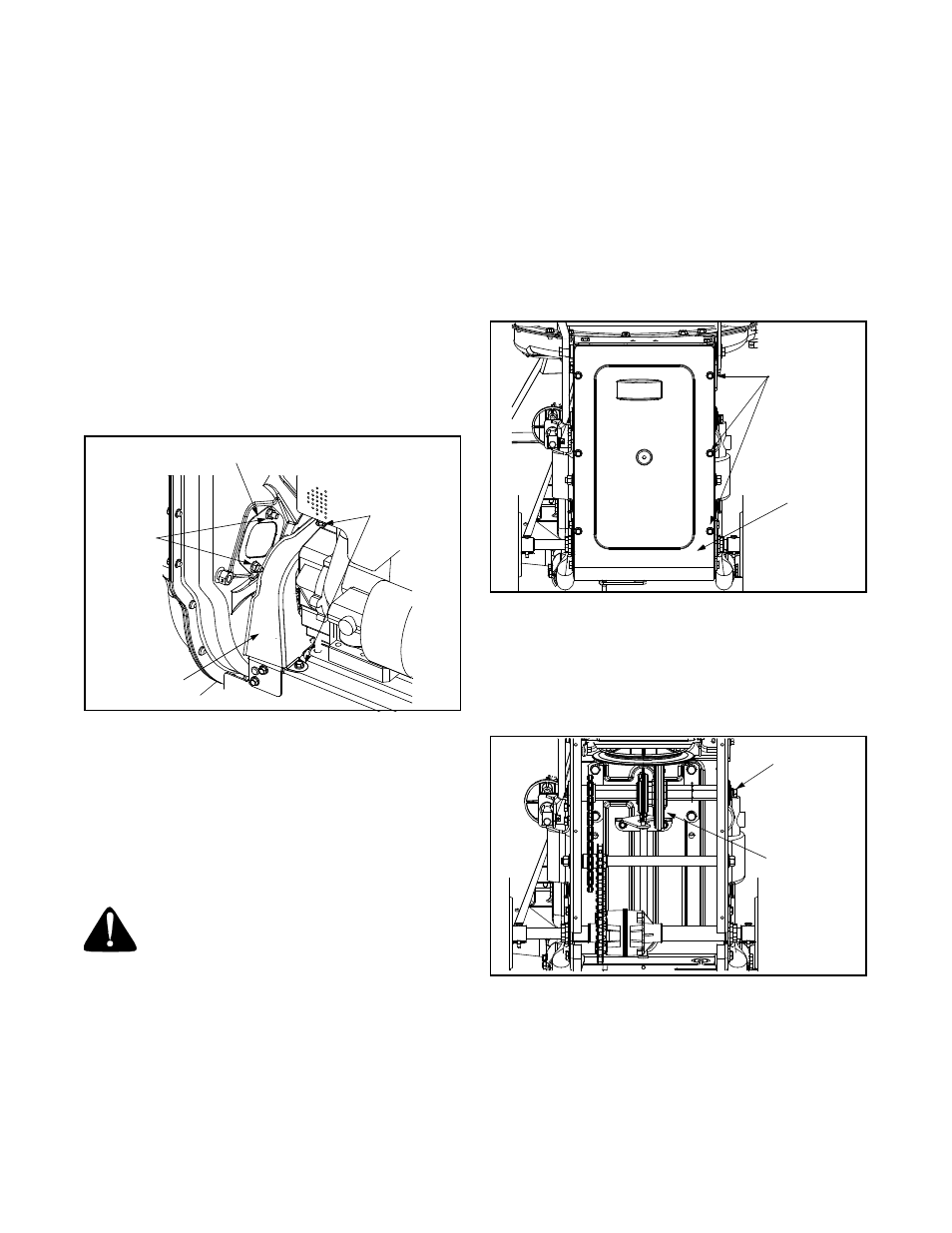

Remove the plastic belt cover on the front of the

engine by removing the two self-tapping screws.

See Figure 14.

Figure 14

•

Remove the access plate by removing two hex lock

nuts. See Figure 14.

•

Locate one of the chipper blades in the access

opening by rotating the impeller assembly by hand.

Remove the chipper blade using a 3/16” allen

wrench and a 1/2” wrench.

•

Remove other blade in the same manner to replace

or sharpen.

WARNING: Use caution when replacing

the blade, wear heavy gloves to avoid a

contact injury with the weld bolts or the

housing while loosening or tightening the

blade.

•

When sharpening blade, follow the original angle of

grind. Also, make sure to remove an equal amount

from each blade and torque hardware 250 - 300 in.

lbs.

NOTE: Make certain blades are reassembled with the

sharp edge facing upward.

Changing The Friction Wheel Rubber

The rubber on the friction wheel is subject to wear and it

should be checked or replaced after 50 hours of

operation. Replace friction wheel rubber if any signs of

wear or cracking are found.

•

Drain the gasoline and oil from the chipper

shredder vacuum.

•

Tip the unit backward so it rests on the handles.

•

Remove the frame cover by removing eight self-

tapping screws from underneath the chipper

shredder vacuum. See Figure 15.

Figure 15

•

Remove the hex shaft from the unit by removing the

hex bolts, lock washers, and flat washers from each

side of the frame. See Figure 16.

•

Hold the friction wheel assembly and slide the hex

shaft out of the unit toward the right side.

Figure 16

•

Remove the six screws, three from each side, from

the friction wheel assembly and remove the friction

wheel rubber from between the friction wheel

plates.

•

Attach the new friction wheel rubber to the friction

wheel assembly and tighten the six screws in

rotation and with equal force.

Belt

Cover

Self-Tapping

Screws

Access Plate

Hex

Lock Nuts

Self-Tapping

Screws

Frame

Cover

Hex Bolt

Lock Washer

Flat Washer

Friction

Wheel