Important, Step 3 – Wayne-Dalton DS-350 User Manual

Page 5

5

STEP 3

INSTALLING MOUNTING ANGLES AND

GUIDES

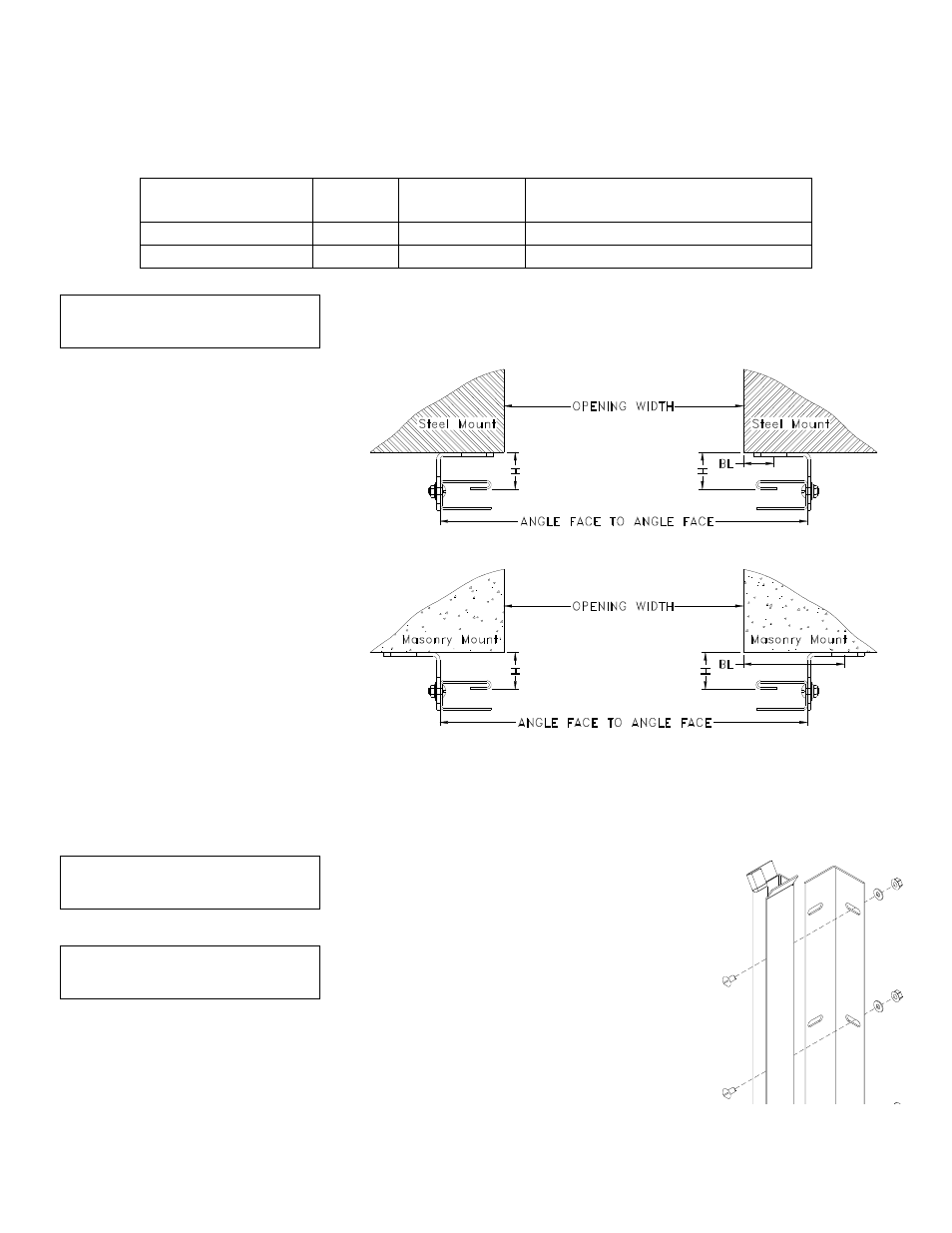

Obtain the appropriate Bolt Line (BL) measurement from the chart below.

Use Opening Width listed on packing

slip. Any variation between the actual opening width and the width listed on the packing slip is to be ignored.

Use BL measurement to locate wall mounting angle for one

jamb only. Second angle will be located using Angle Face to

Angle Face measurement.

Using the BL measurement, loosely

clamp the right hand wall angle to the

right hand jamb. Position the wall angle

such that the BL measurement falls near

the center of the slots. Adjust the wall

angle so that it is level and tighten the

clamp. Install wall angle fasteners in the

centers of the top and bottom slots only

and tighten.

Select the appropriate Angle Face to

Angle Face equation from the chart

above. Add the

opening width listed on

the packing slip to obtain the Angle

Face to Angle Face measurement. Use

this measurement to locate the left hand

wall angle on the left hand jamb and clamp in place. Install the top and bottom bolts in the wall angle. Verify that

both wall angles are level and double check the angle to angle measurement at the top, middle, and bottom to ensure

that the wall angles are properly located. Using a string and a level, ensure that the mounting angles are parallel to

each other, shimming if necessary, to achieve both vertical and horizontal leveling. Now install the remaining bolts

in both wall angles.

Angle Face to Angle Face measurement

must be held to ensure proper door

operation and resistance to windload.

Use of any other fasteners than those

provided must be approved by

manufacturer or building authority and

cannot be of lesser diameter or grade.

Align the guide slots with the slots in the wall angles and fasten guides with the interior

windlock return towards the door jamb using the 5/16-18 x 5/8” truss head bolts,

washers, and flange nuts. Slide guides to set the “H” dimension as shown above at 1-3/4”

prior to tightening the guide fasteners.

OPENING WIDTH

BL

(STEEL)

BL

(MASONRY)

ANGLE FACE TO ANGLE FACE

UP TO 10’ WIDE

1-9/16”

4-15/16”

OPENING WIDTH + 6-11/16”

OVER 10’ WIDE

1-7/16”

4-7/8”

OPENING WIDTH + 6-7/16”

IMPORTANT!

IMPORTANT!

IMPORTANT!