20 owner service, Troubleshooting – Woods Equipment 1050 User Manual

Page 20

20 Owner Service

51861 (Rev. 6/16/2006)

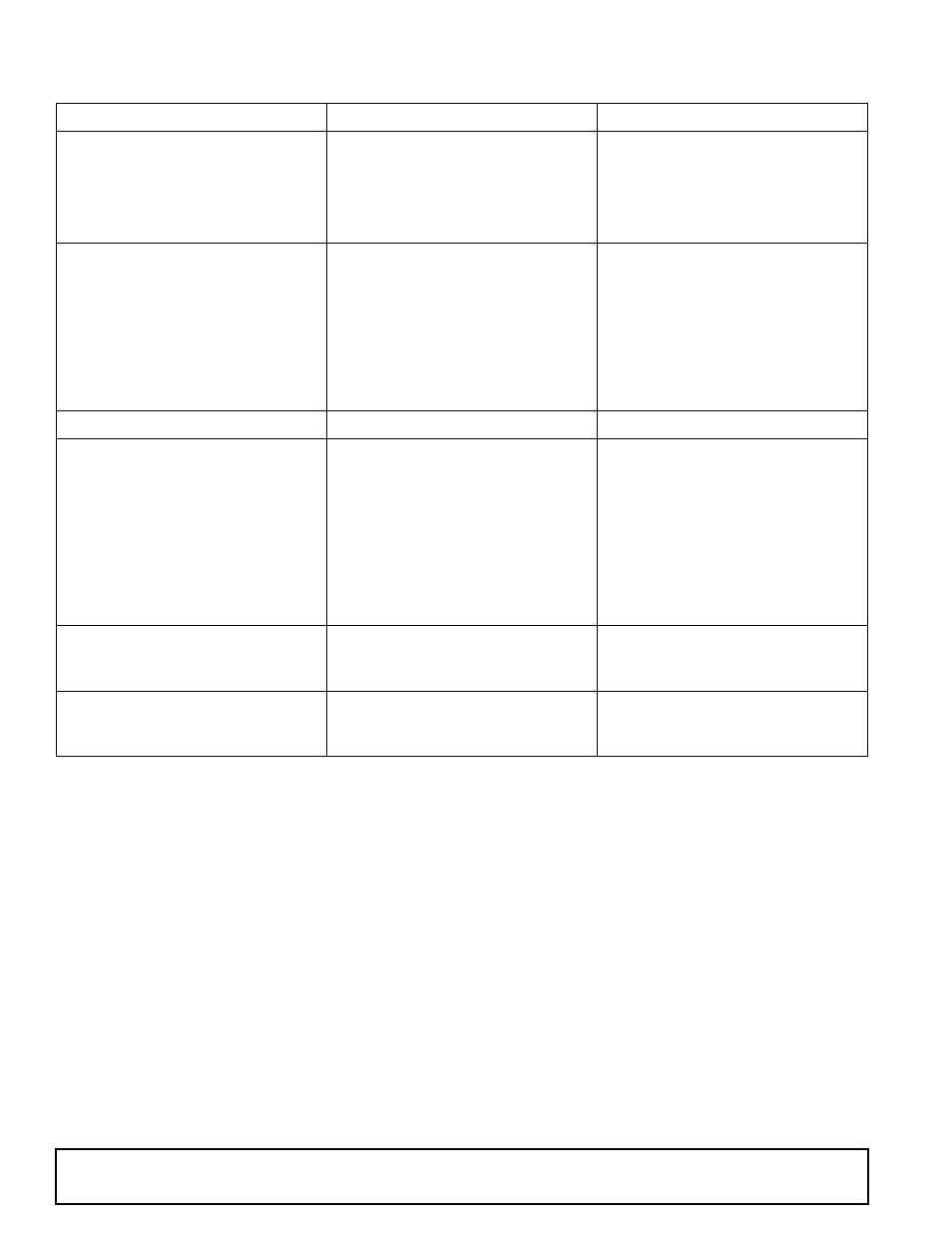

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Noisy pump caused by cavitation

Oil too heavy

Change to proper viscosity.

Oil filter plugged

Replace filter.

Suction line plugged or too small

Clean line and check for size.

Suction line kinked

Replace line.

Oil heating

Oil supply low

Fill reservoir.

Contaminated oil

Drain reservoir, change filter, and

refill with clean oil.

Setting of relief valve too high or

too low

Set to correct pressure.

Pump operating too fast

Do not exceed recommended

rpm PTO speed.

Shaft seal leakage

Worn shaft seal

Replace shaft seal.

Foaming oil

Low oil level

Fill reservoir.

Air leaking into suction line

Tighten fittings.

Wrong kind of oil

Drain and refill reservoir with non-

foaming oil.

Moisture in oil

Keep oil temperature below 180°

and continue to operate as oil

dries out, or replace oil and purge

system if foaming is excessive.

Boom drops as dipper or bucket

cylinder lever is activated while

boom control is in raised position

Load check valve leaking

Clean or replace check valve

assembly.

Jerky operation

Hydraulic hoses plumbed

incorrectly

Check hydraulic plumbing

schematic and correct hose

routing as required.