Service information, Cleaning and maintenance, Energy saving tips – Viking VRBD/VUBD 24" W User Manual

Page 8: Common draft problems

15

SERVICE INFORMATION

It is assumed that your beverage dispenser has been properly installed in accordance with all specifications and local

codes. If your beverage dispenser should fail to operate, review the common draft problems before calling for service.

If service is required:

1. Call your dealer or authorized service agency. The name of the authorized service agency can be obtained from the

dealer or distributor in your area.

2. Have the following information readily available:

•Model Number

•Serial Number

•Date of purchase

•Name of dealer from whom purchased.

3. Clearly describe the problem that you are having.

If you are unable to obtain the name of an authorized service agency, or if you continue to have service problems,

contact Viking at (888) 845-4641 or write to:

VIKING PREFERRED SERVICE

111 Front Street

Greenwood, Mississippi 38930 USA

Record the information indicated below. You will need it if service is ever required. The model and serial number for

your beverage dispenser is located on the front of the unit at the base of the door frame.

Model Number

Serial Number

Date of Purchase

Date Installed

Dealer’s Name

Address

If service is requires installation of parts, use only authorized parts to ensure protection under the warranty.

This manual should remain with the beverage dispenser for future reference.

CLEANING AND MAINTENANCE

Condenser

The condenser tubing under the cabinet for forced air units does not require frequent cleaning. However, satisfactory

cooling depends on adequate ventilation over the condenser. Be sure that nothing obstructs the air flow openings in the

lower front of the cabinet. At least once or twice a year brush or vacuum lint and dirt from the condenser for efficient

performance by unscrewing the grill on the bottom front of the cabinet.

Cabinet

The painted cabinet can be washed with mild soap and water and thoroughly rinsed with clear water. Never use abrasive

scouring powders.

Interior and Door Gasket

Wash interior compartment with mild soap and water. Mix 2 tablespoons of baking soda with one quart of warm water.

Do not use an abrasive powder, solvent, polish cleaner or undiluted detergent.

14

ENERGY SAVING TIPS

Ways to save power, save money, and still enjoy your beverage dispenser.

•Reduce door openings.

•Close the door as soon as you can.

•Keep the coils on bottom of the refrigerator clean.

•Adjust the temperature control to a warmer setting when practical.

•Keep unit away from the stove or other heat sources.

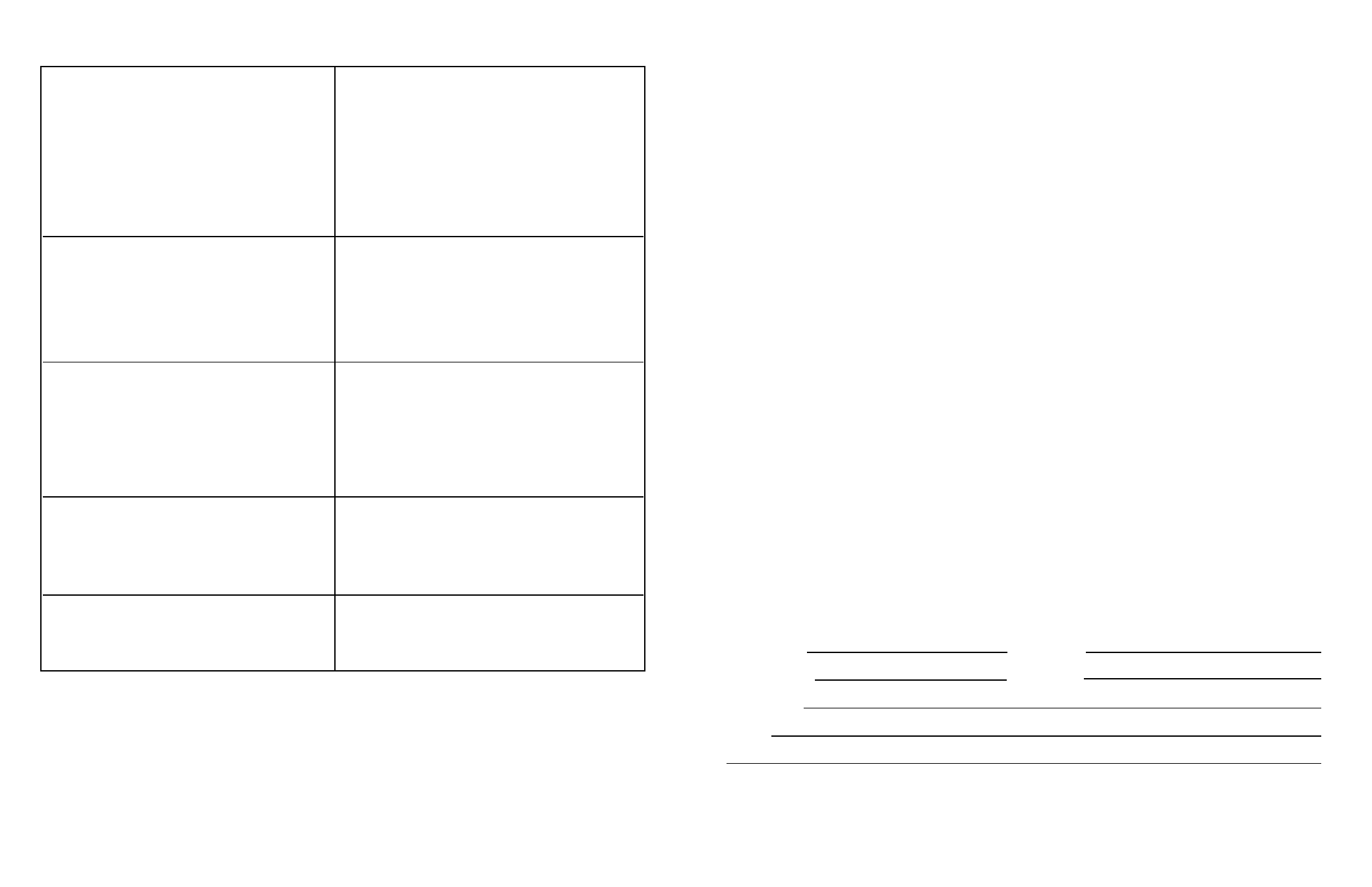

COMMON DRAFT PROBLEMS

DESCRIPTION

CAUSES

Wild Beer

Beer, when drawn, is all foam, or too much foam and

Beer drawn improperly

not enough liquid beer.

Creeping regulator

Applied pressure is set too high

Hot spots in line

Use of non-insulated beer line

Beer runs are too long for proper cooling

Tapped into a warm keg

Cooler malfunctioning

Kinks, dents, twists, or other obstructions in line

Faucets in bad, dirty or worn condition

Cloudy Beer

When beer in glass appears hazy, not clear

Frozen or nearly frozen beer

Old beer

Beer that has been unrefrigerated for long periods of

time

Dirty glass

Dirty faucet

Unrefrigerated foods placed on top of cold keg

Contaminated air source

Flat Beer

Foamy head disappears quickly;

Dirty glasses

beer lacks usual zestful brewery fresh flavor

Sluggish regulator

Applied pressure is set too low

CO2 is turned off at night

Contaminated air source (associated with compressed

air)

Moisture in air system

Beer too cold

Loose tap or vent connections

False Head

Large soap-like bubbles, head dissolves very quickly

Applied pressure required does not correspond to

beer temperature

Small beer line into a large faucet shank

Beer lines warmer than beer in keg

Dry glasses

Improper pour

Unpalatable Beer

Off-Taste

Dirty or old beer lines

Dirty faucet

Contaminated air source, or unfiltered

Unsanitary bar conditions