True food international equipment, inc, Ar2-28 instructions for use, Description indications installation – True Manufacturing Company TGU-2 User Manual

Page 22: Operation, Wiring diagrams technical data, Display, Info menu, Stand-by, Keypad lock, Selection of second parameter group

............ www.truemfg.com ............

True Food International Equipment, Inc.

20

20

Thank you for having chosen an LAE electronic product. Before installing the instrument, please read this instruction booklet carefully in order to ensure safe

installation and optimum performance.

AR2-28 INSTRUCTIONS FOR USE

Fig.1 - Front panel

DESCRIPTION

INDICATIONS

INSTALLATION

The AR2-28 controller, size 107x95x47 mm (WxHxD), is to be secured to a DIN rail in such a position as to ensure that no liquid infiltrates causing serious

■

damage and compromising safety.

Make sure that electrical connections comply with the paragraph “wiring diagrams”. To reduce the effects of electromagnetic disturbance, keep the sensor

■

and signal cables well separate from the power wires.

Place the probe T1 inside the room in a point that truly represents the temperature of the stored product.

■

Place the probe T2 on the evaporator where there is the maximum formation of frost.

■

The function of probe T3 is determined by the parameter T3. With

■

T3=DSP the probe measures the temperature to be displayed. With T3=CND the probe

measures the condenser temperature, it must therefore be placed between the fins of the condensing unit. With

T3=2EU the probe measures the temperature

of the second evaporator and it must therefore be placed where there is the maximum formation of frost. With

T3=NON, the third probe is disabled.

OPERATION

DISPLAY

During normal operation, the display shows either the temperature measured or one of the following indications:

Defrost in progress

Condenser high pressure alarm

Controller in stand-by

Room high temperature alarm

Condenser clean warning

Room low temperature alarm

Door open alarm

Probe T1 failure

Condenser high temperature alarm

Probe T2 failure

Probe T3 failure

INFO MENU

The information available in this menu is:

Instant probe 1 temperature

End time for timed actions

*

Instant probe 2 temperature

Maximum probe 1 temperature recorded

*

Instant probe 3 temperature

Minimum probe 1 temperature recorded

Minutes of the Real Time Clock

** Compressor working weeks

Hours of the Real Time Clock

Keypad state lock

Start time for timed actions

*: displayed only if enabled (see §Configuration Parameters) **: displayed only if

ACC > 0

Access to menu and information displayed.

Press and immediately release button

■

.

With button

■

or select the data to be displayed.

Press button

■

to display value.

To exit from the menu, press button

■

or wait for 10 seconds.

Reset of THI, TLO, CND recordings.

With button

■

or select the data to be reset.

Display the value with button

■

.

While keeping button

■

pressed, use button

.

SETPOINT : display and modification

Press button

■

for at least half second, to display the setpoint value.

By keeping button

■

pressed, use button or to set the desired value

(adjustment is within the minimum

SPL and the maximum SPH limit).

When button

■

is released, the new value is stored.

STAND-BY

Button , when pressed for 3 seconds, allows the controller to be put on a standby or output control to be resumed (with

SB=YES only).

KEYPAD LOCK

The keypad lock avoids undesired, potentially dangerous operations, which might be attempted when the controller is operating in a public place. In the INFO

menu, set parameter

LOC=YES to inhibit all functions of the buttons. To resume normal operation of keypad, adjust setting so that LOC=NO.

SELECTION OF SECOND PARAMETER GROUP

It’s possible to select control parameters between two different pre-programmed groups, in order for the fundamental control parameters to be adapted quickly

to changing needs. Changeover from Group

I to Group II (and vice versa) may take place MANUALLY by pressing button for 2 seconds (with IISM=MAN),

or AUTOMATICALLY when heavy duty conditions are detected (with

IISM=HDD), or when IISM=DI2 and the AUXILIARY INPUT DI2 is activated (the activation

of DI2 selects Group

II), or finally at the time specified by STT and EDT parameters (with IISM=RTC). If IISM=NON, switchover to Group II is inhibited. The

activation of Group

II is signalled by the lighting up of the relevant LED on the controller display.

REAL TIME CLOCK SETTING

The Real Time Clock (RTC) can be adjusted directly from the Info Menu (see Setpoint modification procedure). Tens of minutes MIN range from 0 to 59 and

Hours HRS range from 0 to 23. If RTC is adjusted just before an upcoming change of hour, verify the correctness of the setting again. The RTC does not

automatically change upon Daylight Saving Time.

DEFROST

Automatic defrost. Defrost starts automatically at fixed time-intervals or at programmed scheduled (up to six per 24 hours).

Timed defrost

■

. With

DFM=TIM defrosts take place at regular intervals when the timer reaches the value of DFT. For example, with DFM=TIM and DFT=06,

a defrost will take place every 6 hours.

Scheduled defrost

■

. With

DFM=RTC defrost takes place at time specified by DH1...DH6. The format of time is “HH.M”, where HH are hours and M are tens

STT

HH.M

Start time for timed actions.

Time at which the second parameter group or the light output is switched. Accepted values go from 00.0 to 23.5. Example:

STT=8.3 and IISM=RTC means that at 8.30 AM the second group will be activated.

EDT

HH.M

End time for timed actions. See STT.

LSM

NON;

MAN;

RT0;

RT1;

DOR

Light control mode

NON : light output not controlled.

MAN : light ouput controlled through button (if OAx=LGT).

RT0 : light output switched on at EDT time, off at STT time.

RT1 : light output switched on at STT time, off at EDT time.

DOR : light ouput switched on when door is opened (if OAx=LGT).

OA1

NON;

0-1;

LGT;

2CU;

2EU;

AL0;

AL1

AUX 1 output operation

NON : output disabled (always off).

0-1 : the relay contacts follow the on/standby state of controller.

LGT : output enabled for light control.

2CU : output programmed for the control of an auxiliary compressor.

2EU : output enabled for the control of the electrical defrost of a second evaporator.

AL0 : contacts open when an alarm condition occurs.

AL1 : contacts make when an alarm condition occurs.

OA2

See OA1

AUX2 output operation. See OA1.

2CD

0...120 sec Auxiliary compressor start delay. If OAx=2CU the auxiliary output is switched on with a delay of 2CD seconds after the main

compressor has cut-in. Both compressors are turned off at the same time.

INP

SN4; ST1

Temperature sensor selection. With INP=SN4, the probes must be the LAE models SN4..; with INP = ST1, the probes must

be the LAE models ST1...

OS1 -12.5..12.5°C Probe T1 offset.

T2

NO/YES

Probe T2 enabling (evaporator).

OS2 -12.5..12.5°C Probe T2 offset.

T3

NON;

DSP;

CND;

2EU

Auxiliary probe T3 operation

NON : probe T3 not fitted.

DSP : temperature T3 to be displayed.

CND : condenser temperature measurement.

2EU : second evaporator temperature measurement.

OS3 -12.5..12.5°C Probe 3 offset.

TLD

1...30 min

Delay for minimum temperature (TLO) and maximum temperature (THI) logging.

SIM

0...100

Display slowdown.

ADR

1...255

AR2-28 address for PC communication.

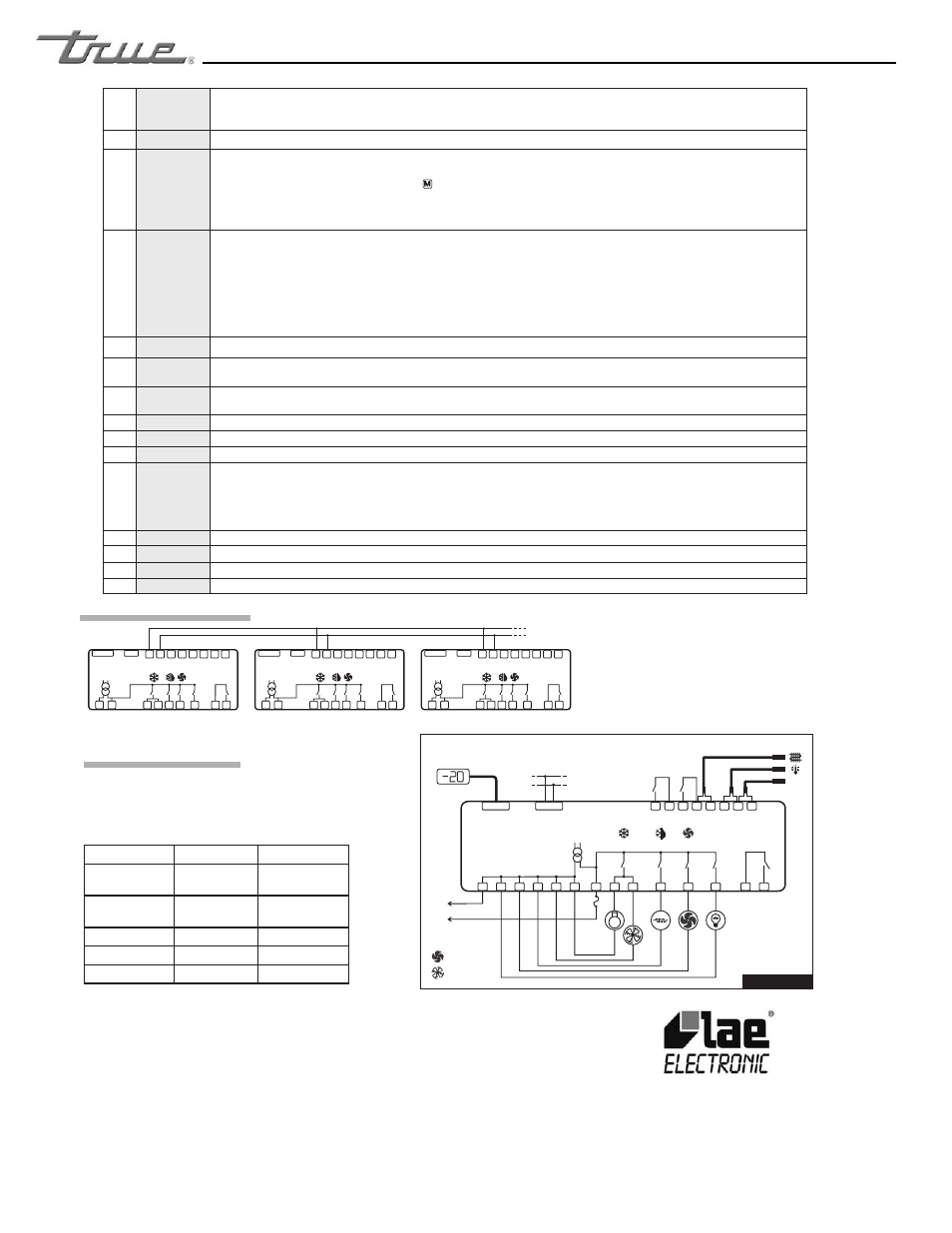

WIRING DIAGRAMS

TECHNICAL DATA

Power supply

AR2-28.…D 12Vac/dc ±10%, 3W

AR2-28....E 230Vac±10%, 50/60Hz, 3W

AR2-28....U 115Vac±10%, 50/60Hz, 3W

Relay output max loads (240Vac)

AR2-28..S/T..-. AR2-28..Q/R..-.

Compressor

16A resistive

8 FLA 48 RLA

12A resistive

8 FLA 48 RLA

Evap. Fan

8A resistive

2 FLA 12 RLA

8A resistive

2 FLA 12 RLA

Defrost

16A resistive

12A resistive

Auxiliary loads 1 7A resistive

7A resistive

Auxiliary loads 2 7A resistive

7A resistive

Input

NTC 10KΩ@25°C LAE Part No. SN4...

PTC 1000Ω@25°C LAE Part No. ST1…

Measurement Range

-50…120°C, -55…240°F

-50 / -9.9 … 19.9 / 80°C (NTC10K only)

Measurement accuracy

<0.5°C within the measurement range

Real Time Clock battery

>150 hours; self-rechargeable

VIA PADOVA, 25

31046 ODERZO /TV /ITALY

TEL. +39 - 0422 815320

FAX +39 - 0422 814073

www.lae-electronic.com

E-mail: [email protected]

Thermostat output

Fan output

Alarm

Defrost output

Activation of 2nd parameter set

Manual activation / Increase button.

Exit / Stand-by button.

Info / Setpoint button.

Manual defrost / Decrease button.

Operating conditions

-10 … +50°C; 15%...80% r.H.

CE - UL (Approvals and Reference norms)

EN60730-1; EN60730-2-9; EN55022 (Class B);

EN50082-1

SA32385, UL 60730-1A

AR2-28C1S5E-B

DI2

Maximum total current 17.5A

Power

Supply

L

N

data I/O

RS485

PC comm.

LCD-5S

or

RU33

16(4)A

16(8)A

A

B

8(2)A

7A

Evaporator fan

Condenser fan

T3

T2

T1

remote

Door

7A

AUX 2

AUX 1

Aux

14

15

16

17

18

19

9

10

11

7

8

6

1

2

26

29

31

32

33

28

30

27

FUSE

-

-

-

+

+

+

31

29

30

27

28

9

14

33

32

DI2

26

T3

8

6

7

10

AR2-28C1S5E-B

11

1

2

AUX2

AUX1

T2

T1

Door

data

remote

31

29

30

27

28

9

14

33

32

DI2

26

T3

8

6

7

10

AR2-28C1S5E-B

11

1

2

AUX2

AUX1

T2

T1

Door

data

remote

31

29

30

27

28

9

14

32

33

DI2

26

T3

8

6

7

10

AR2-28C1S5E-B

11

1

2

AUX2

AUX1

T2

T1

Door

data

remote

Fig.3 Connection for synchronising defrost start and termination