Chute clean-out tool, Drift cutters (on models so equipped), Section 3: maintaining your snow thrower – Troy-Bilt 1030 User Manual

Page 12: General recommendations, Lubrication (see figure 10), Drift cutters, Lubrication

12

Chute Clean-Out Tool

The clean-out tool is conveniently fastened to the rear

of the auger housing with a mounting clip. Never use

your hand to clean a clogged chute.

1.

Release both the auger control and the

drive/auger

control lock.

2.

Stop the engine by moving the throttle to the stop

position.

3.

Remove the clean-out tool from the mounting clip.

4.

Use the shovel-shaped end of the clean-out tool to

remove any snow and ice in the chute assembly.

5.

Re-fasten the clean-out tool to the mounting clip on

the rear of the auger housing and restart engine.

6.

While standing in the operator’s position (behind

the snow thrower), engage the auger control for a

few seconds to clear any remaining snow or ice

from the chute assembly before continuing to clear

snow.

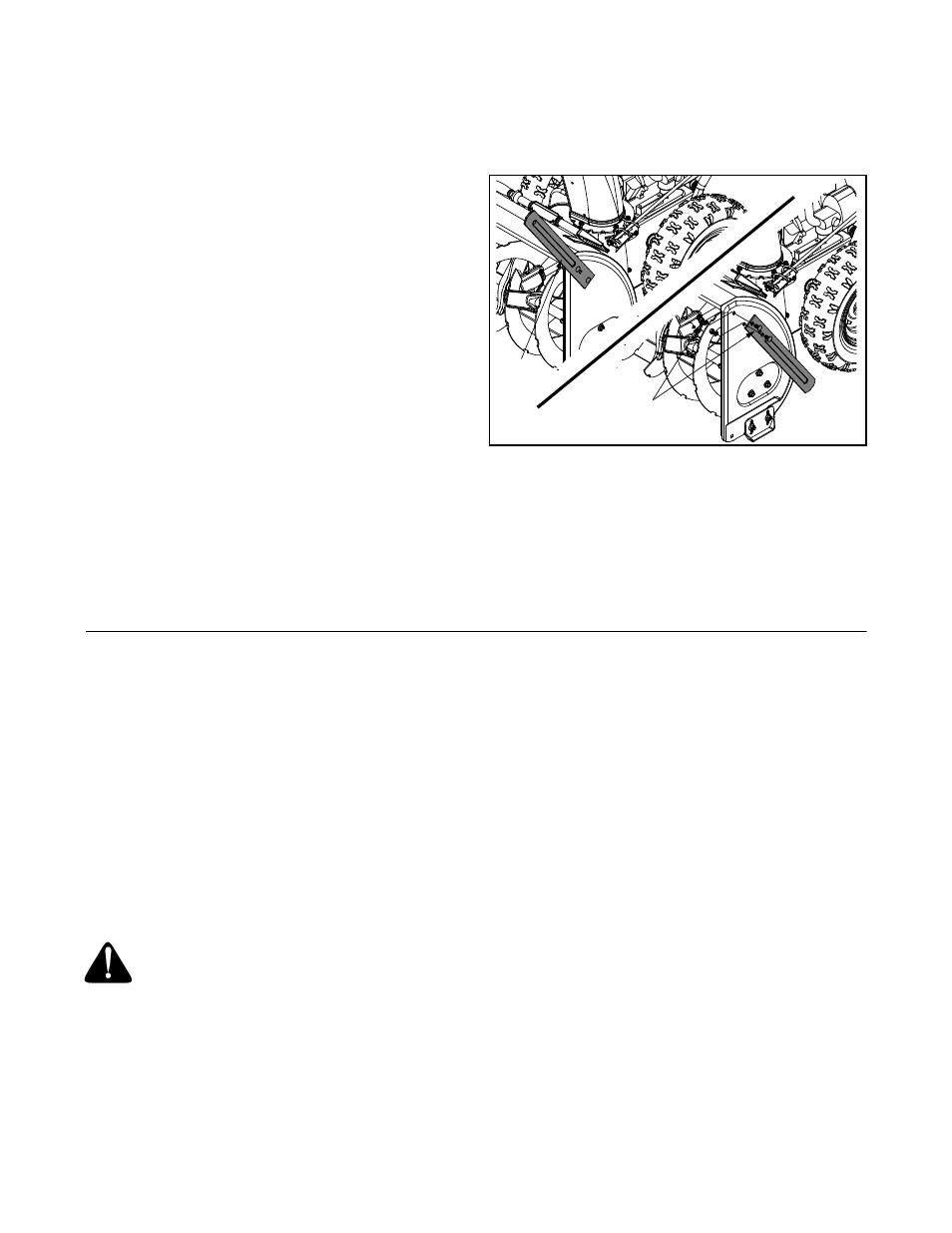

Drift Cutters

(on models so equipped)

Drift cutters should be used when operating the snow

thrower in heavy drift conditions.

On models so equipped, drift cutters are assembled to

the auger housing inverted. Remove the carriage bolts

by unthreading the hex nuts which secure them, and

reinstall the drift cutters in their proper position before

operating the snow thrower. See Figure 9 .

Figure 9

If your unit is not equipped with drift cutters, contact

Customer Support as instructed on page 2 for

information regarding price and availability.

Snow Thrower ModelDrift Cutter Kit:

All models-OEM-390-679

SECTION 3: MAINTAINING YOUR SNOW THROWER

General Recommendations

•

Always observe safety rules when performing any

maintenance.

•

The warranty on this snow thrower does not cover

items that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, operator must maintain the snow thrower

as instructed in this manual.

•

Some adjustments will have to be made

periodically to maintain your unit properly.

•

Periodically check all fasteners and make sure

these are tight.

Lubrication

•

Drive Mechanism: Once a season or after every

25 hours of operation, remove rear frame cover and

lubricate any chains, sprockets, gears, bearings,

and shafts with engine oil or lubricant spray.

IMPORTANT:

Avoid oil spillage on rubber friction wheel

and aluminum drive plate.

•

Gear Shaft: Once a season, lubricate the gear

shaft with a penetrating oil, but not grease. Refer to

Figure 22 on page 17.

•

Gear Case: The gear case is lubricated with

grease at the factory and does not require regular

lubrication. However, if disassembled for any

reason, lubricate with 2 ounces of Shell Alvania™

grease (part # 737-0168). Before reassembling,

remove old sealant and apply new sealant.

To check the level of grease in the gear case, remove

the vent plug on top of the gear case. You may, if

necessary, add grease using a grease gun and the

grease fitting on the side of the gear case.

IMPORTANT:

Do not overfill the gear case, since

damage to the seals could result. Be sure the vent plug

is free of grease in order to relieve pressure.

Carriage Screws /

Hex Nuts

Drift

Cutter

WARNING:

Always stop engine and

disconnect spark plug wire before

performing any maintenance or adjustments.

Always wear safety glasses during operation

or while performing any adjustments or

repairs.