Changing engine oil, Spark plug – Troy-Bilt 2100 User Manual

Page 17

Changing Engine Oil

NOTE: Check the oil level before each use and after every five

hours of operation to be sure the correct oil level is maintained.

Refer to Checking Oil Level in the Operation Section

Drain fuel from the tank by running the engine until the

1.

fuel tank is empty. Be sure the fuel fill cap is secure.

Place a suitable oil collection container under the oil drain

2.

plug.

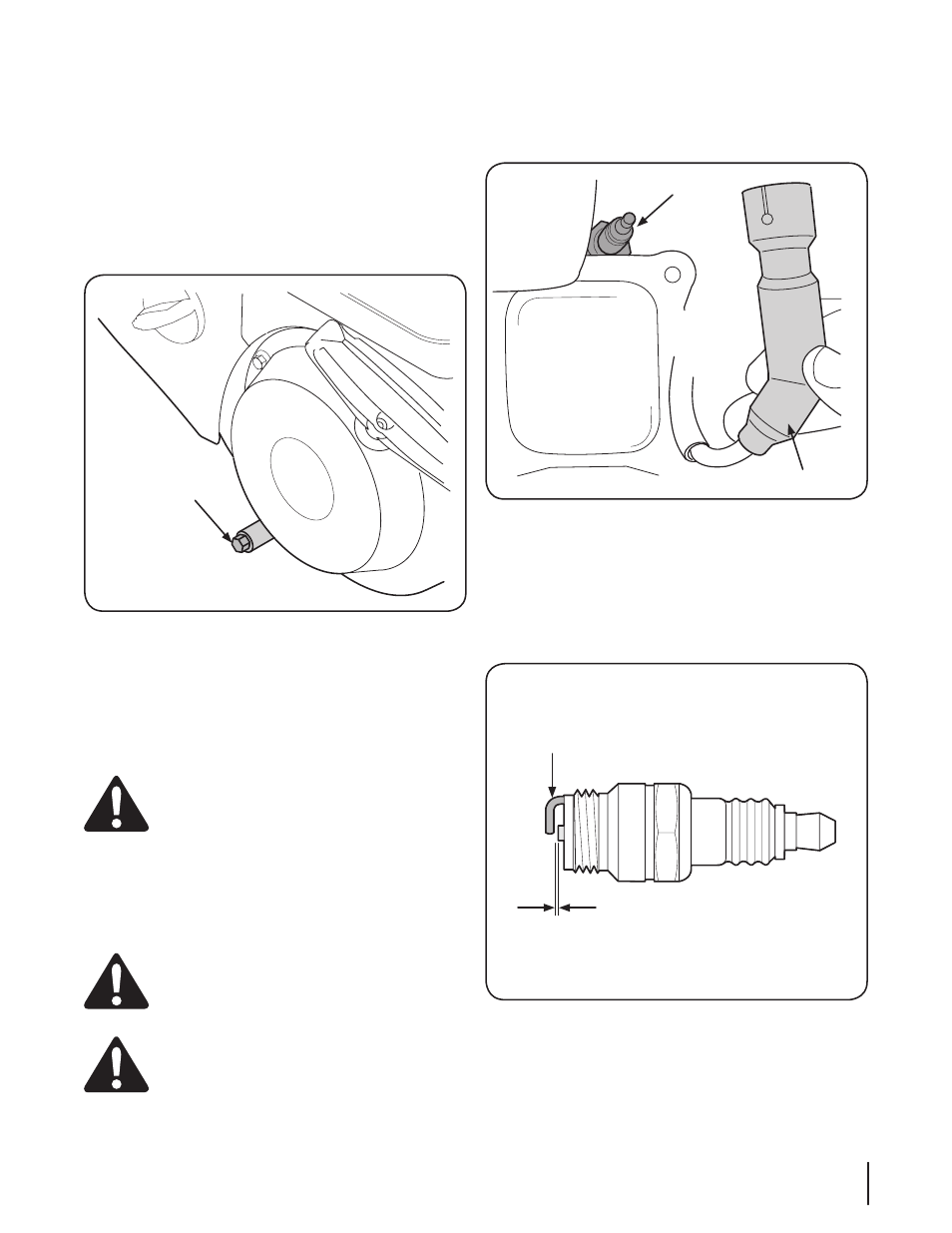

Remove the oil drain plug, Figure 7-3.

3.

Tip the engine to drain oil into the container. Used oil must

4.

be disposed of at a proper collection center.

Reinstall the drain plug and tighten it securely.

5.

Refill with the recommended oil and check the oil level,

6.

refer to Assembly & Set-Up Section for instructions.

Reinstall the oil filler cap/dipstick securely.

7.

CAUTION:

Thoroughly wash your hands with soap

and water as soon as possible after handling

used oil.

NOTE:

Please dispose of used motor oil in a manner that is

friendly to the environment. Take it to a recycling center or other

collection center.

Spark Plug

WARNING!

DO NOT check for a spark with the

spark plug removed. DO NOT crank the engine with

the spark plug removed.

WARNING!

If the engine has been running, the

muffler will be very hot. Be careful not to touch the

muffler.

To ensure proper engine operation, the spark plug must be

properly gapped and free of deposits.

Remove the spark plug boot and use a spark plug wrench

1.

to remove the plug, Fig. 7-4.

Visually inspect the spark plug. Discard the spark plug if

2.

there is any apparent wear, or if the insulator is cracked or

chipped. Clean the spark plug with a wire brush if it is to be

reused.

Measure the plug gap with a feeler gauge. Correct as

3.

necessary by bending the side electrode, Fig. 7-5. The gap

should be set to .02-.03 inches (0.60-0.80 mm).

Check that the spark plug washer is in good condition

4.

and thread the spark plug in by hand to prevent cross-

threading.

Figure 7-4

Spark Plug

Spark Plug Boot

Oil Plug

Figure 7-1

.02-.03 in.

(0.60-0.80 mm)

Electrode

Figure 7-5

17

s

ectiOn

7 — e

ngine

M

aintenance