Taylor 390 User Manual

Page 18

14

Model 390

Operating Procedures

Section 8

Troubleshooting Guide

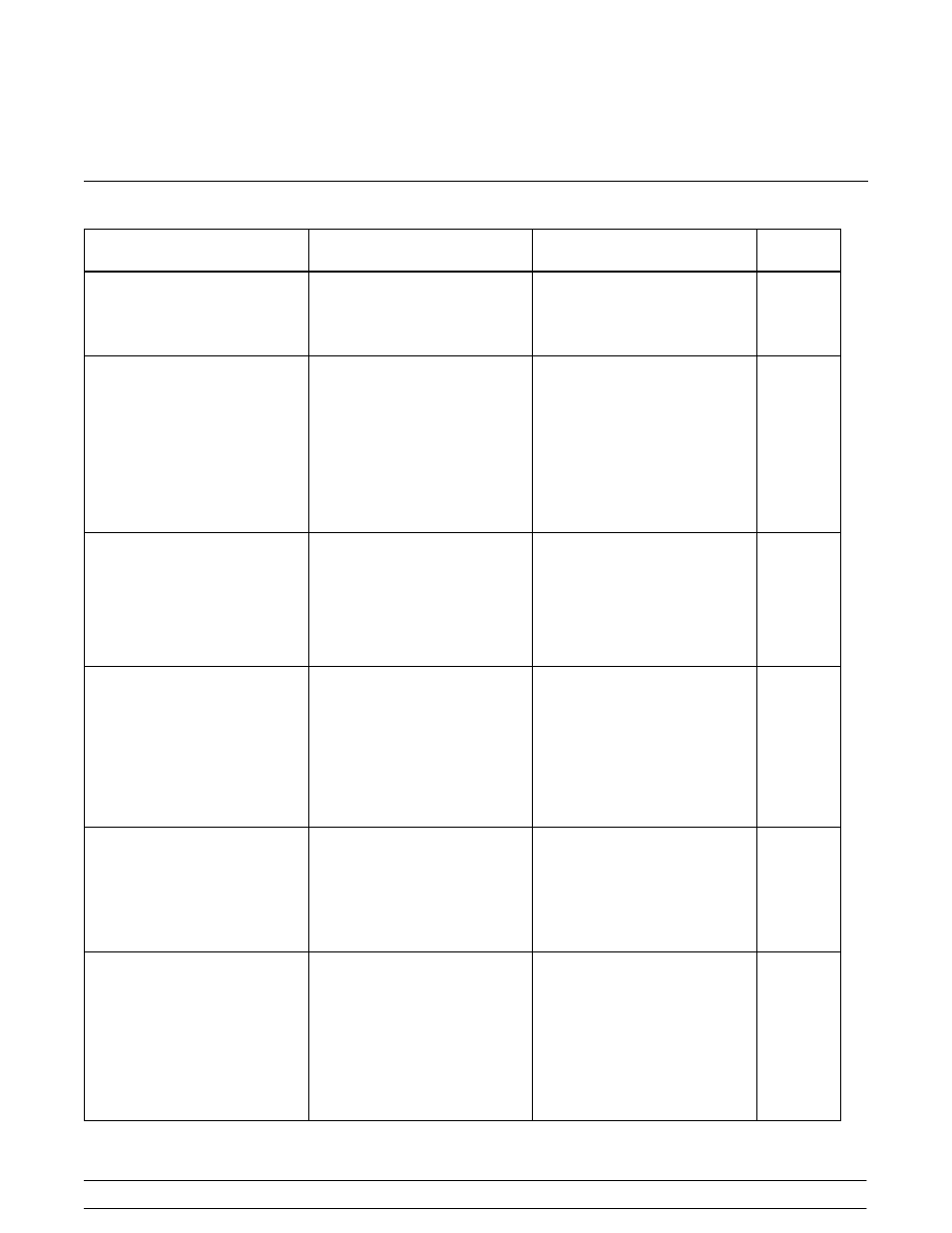

PROBLEM

PROBABLE CAUSE

REMEDY

PAGE

REF.

1. No product being

dispensed with draw valve

opened.

a. Improper mixing of

product.

a. Carefully follow directions

for mixing product.

----

b. Mix low condition.

b. Add mix to mix hopper.

6

2. Product too thin.

a. Improper mixing of

product.

a. Carefully follow directions

for mixing product.

----

b. Missing, incorrectly

installed or bad scraper

blades.

b. Replace or install correctly.

7

c. Consistency control needs

adjusting.

c. Contact a service

technician.

----

3. Product too stiff.

a. Consistency control knob

needs adjusting.

a. Contact a service

technician.

----

b. Improper mixing of

product.

b. Carefully follow directions

for mixing product.

----

c. Insufficient product in the

freezing cylinder.

c. Keep hopper full of mix.

6

4. Scored walls of freezing

cylinder.

a. Broken beater pins.

a. Repair or replace beater

assembly.

----

b. Gear unit out of alignment.

b. Contact a service

technician.

----

c. Bent beater assembly.

c. Repair or replace.

----

d. Missing front bearing.

d. Replace or install front

bearing.

7

5. Unable to remove drive

shaft.

a. Lubrication on hex end of

drive shaft.

a. Do not lubricate the hex

end. Contact service

technician for removal.

7

b. Rounded corners of the

drive shaft, drive coupling

or both.

b. Replace drive shaft, drive

coupling or both.

----

6. Excessive mix leakage in

rear drip pan.

a. Improper or inadequate

lubrication on drive shaft

o-ring or seal on drive

shaft.

a. Use an approved food

grade lubricant (example:

Taylor Lube) and follow

lubrication procedures.

7

b. Bad or missing o-ring or

seal on drive shaft.

b. Replace rubber parts every

3 months.

16

c. Worn rear shell bearing.

c. Contact a service

technician for replacement.

----