System evacuation, Installer’s guide – Trane 2TTB3 User Manual

Page 3

18-AC56D1-1

3

Installer’s Guide

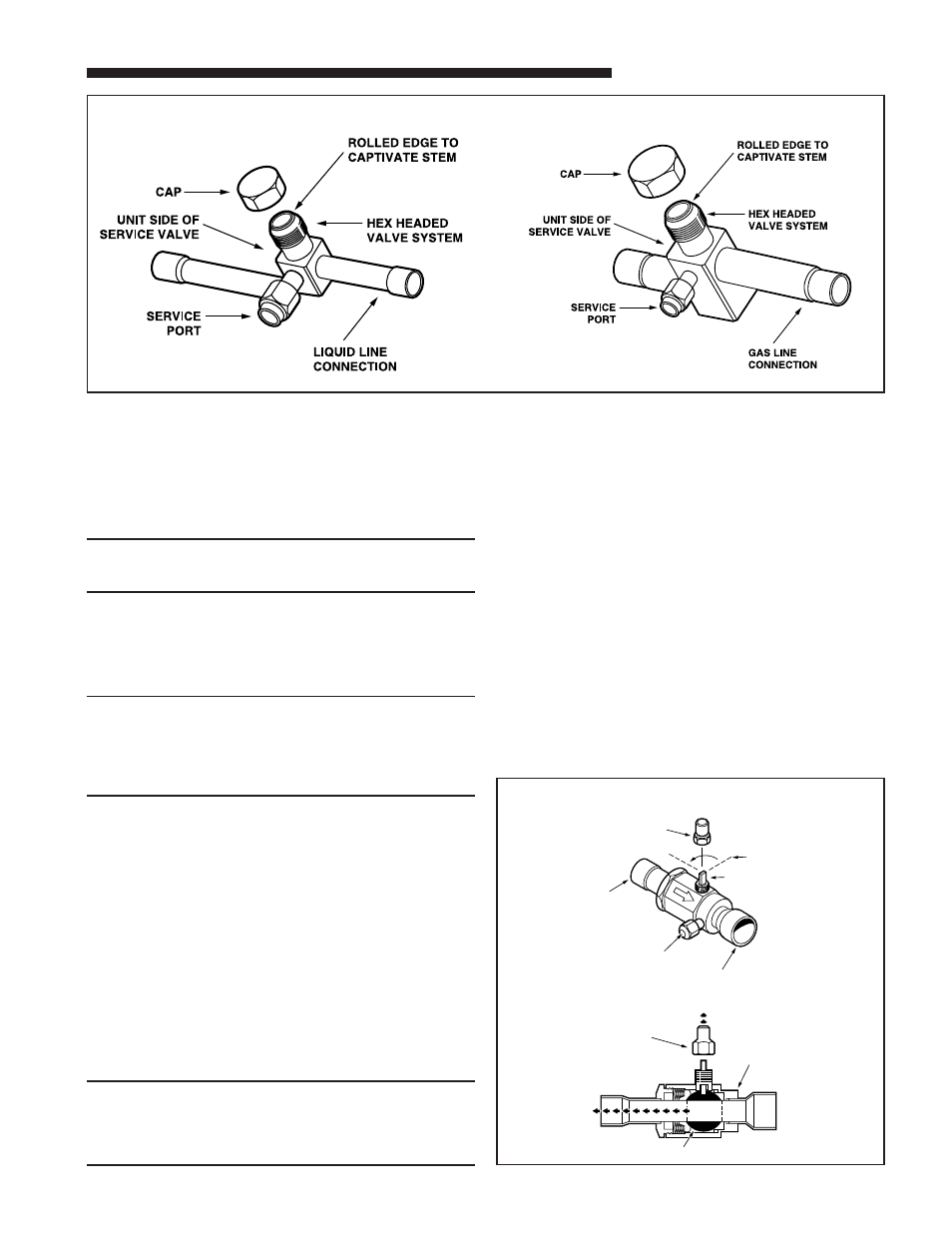

After the brazing operation of refrigerant lines to both the

outdoor and indoor unit is completed, the field brazed

connections must be checked for leaks. Pressurize through

the service valve ports, the indoor unit and field refrigerant

lines with dry nitrogen to 350-400 psi. Use soap bubbles or

other leak-checking methods to see that all field joints are

leak-free! If not, release pressure; then repair!

SYSTEM EVACUATION

NOTE:

Since the outdoor unit has a refrigerant charge, the gas and

liquid line valves must remain closed.

1. Upon completion of leak check, evacuate the refrigerant

lines and indoor coil before opening the gas and liquid

line valves.

2. Attach appropriate hoses from manifold gauge to gas

and liquid line pressure taps.

NOTE:

Unnecessary switching of hoses can be avoided and

complete evacuation of all lines leading to sealed system

can be accomplished with manifold center hose and

connecting branch hose to a cylinder of HCFC-22 and

vacuum pump.

3. Attach center hose of manifold gauges to vacuum pump.

4. Evacuate until the micron gauge reads no higher than

350 microns.

5. Close off valve to vacuum pump and observe the micron

gauge. If gauge pressure rises above 500 microns in one (1)

minute, then evacuation is incomplete or system has a leak.

6. If vacuum gauge does not rise above 500 microns in

one (1) minute, the evacuation should be complete.

7. With vacuum pump and micron gauge blanked off,

open valve on HCFC-22 cylinder and charge refriger-

ant lines and indoor coil with vapor to tank pressure

of HCFC-22 supply.

8. Close valve on HCFC-22 supply cylinder. Close valves

on manifold gauge set and remove refrigerant charging

hoses from liquid and gas pressure tap ports.

NOTE:

A 3/16" Allen wrench is required to open liquid line service

valve. A 1/4" Open End or Adjustable wrench is required to

open gas line valve. A 3/4" Open End wrench is required to

take off the valve stem cap.

9. The liquid line shut-off valve can now be opened. Remove

shut-off valve cap. Fully insert hex wrench into the stem

and backout counterclockwise until valve stem just touches

rolled edge (approximately five [5] turns) observing

WARNING statement on page 2. See Figure 3.

10. Replace liquid service pressure tap port cap and valve

stem cap. These caps MUST BE REPLACED to

prevent leaks. Replace valve stem cap and pressure tap

cap finger tight, then tighten an additional 1/6 turn.

11. The gas valve can now be opened. Open the gas valve by

removing the shut-off valve cap and turning the valve

stem 1/4 turn counterclockwise, using 1/4" Open End or

Adjustable wrench. See Figure 4.

12. The gas valve is now open for refrigerant flow. Replace

valve stem cap to prevent leaks. Again, these caps

MUST BE REPLACED to prevent leaks. Replace valve

stem cap and pressure tap cap finger tight, then tighten

an additional 1/6 turn. See Figure 4.

If refrigerant lines are longer than 15 feet and/or a

different size than recommended, it will be necessary to

adjust system refrigerant charge upon completion of

installation. See page 6 or in the unit Service Facts.

LIQUID LINE SERVICE VALVE

3

CAP

1/4 TURN ONLY

COUNTERCLOCKWISE

FOR FULL OPEN

POSITION

VALVE STEM

GAS LINE CONNECTION

UNIT SIDE

OF VALVE

CAP

BODY

COOLING

CORE

PRESSURE TAP PORT

GAS LINE BALL SERVICE VALVE

4

GAS LINE SERVICE VALVE