Omega PSW20 User Manual

Page 2

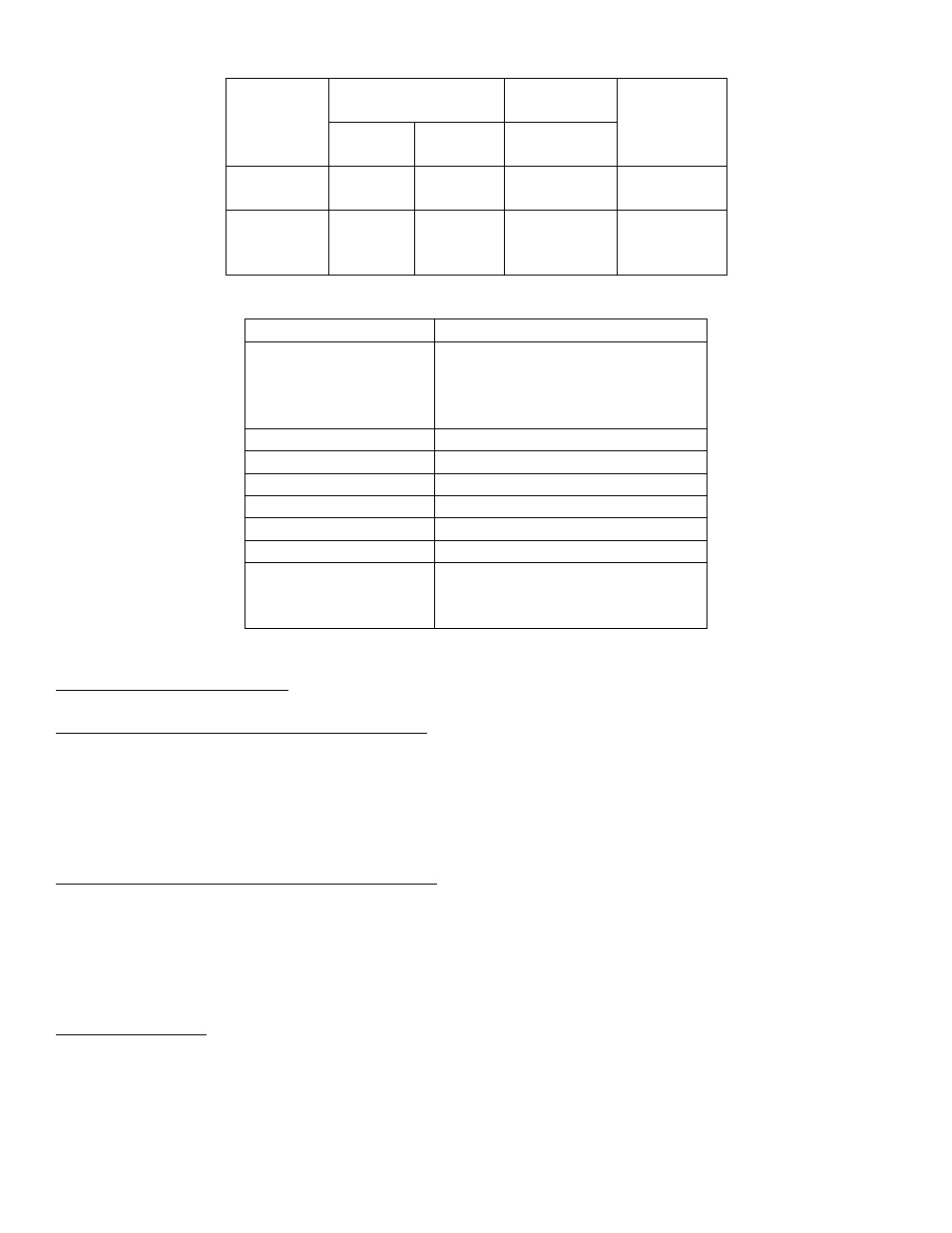

Standard

Electrical rating

Repeat

Accuracy

Part

Number

Max.

Resistive

Min

Resistive

Constant

Temperature

Contact

Resistance

(ohms)

PSW20A

750ma

250VAC

5 ma

3 VDC

+/- 4%

0.04

PSW20B

1 amp

250

VAC

5 ma

3 VDC

+/- 3%

0.02

Body

Acetal

Diaphragm

EPDM is standard; Nitrile

available. NOTE: EPDM should

not be used in petroleum

applications

Contacts

Gold plated silver

Springs

Plated phosphor bronze

Terminals

Plated copper or brass

Adjusting screw

Stainless steel or zinc plated SS

Weight

9 grams (0.3oz)

Operating temperature

-30 C to +65 C (-23F to 149F)

Listings

UL recognized for 100,000

operations

CSA certified

Connections and Adjustment

Pressure Switching – Normally Open Contacts

Connect the pressure source to inlet port B (see diagram) and set the adjusting screw to the desired pressure.

Turning the screw clockwise narrows the gap between contacts and decreases the pressure set point. Turning the

pressure adjusting screw counterclockwise increases the set point. Note: the media entering the

diaphragm through Port B is separated from the electrical contacts by the diaphragm.

Pressure Switching – Normally Closed Contacts

Connect the pressure source to Port A and monitor continuity across the terminals. Slowly turn the adjusting

screw clockwise, narrowing the gap between contacts until the contacts are closed. Apply the set point pressure

which will open the contacts. Continue to turn the adjusting screw clockwise until the contacts

make and break at the desired point.

Vacuum Switching

Repeat the above procedure using Port A for Normally Open Contacts and Port B for Normally Closed

Contacts.