Configuration – Omega LDP-124 User Manual

Page 11

Page : 10

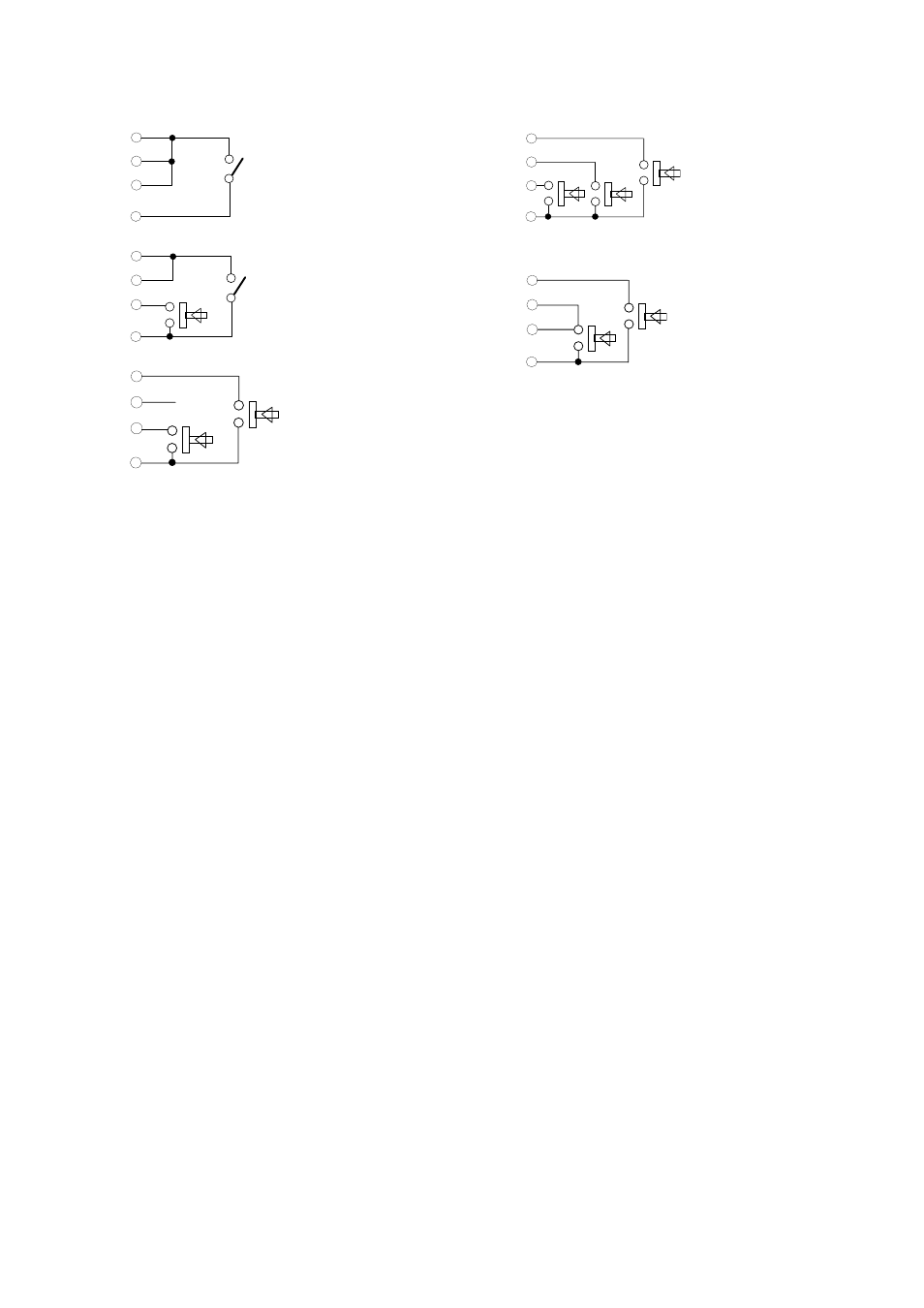

9.2.2.- CONNECTION EXAMPLES

Different interlinking of the three control lines will produce different operating modes:

Close contact A = reset and run

Open contact A = stop

Stop

Start

Reset

GND

Stop

Start

Reset

GND

Stop

Start

Reset

GND

With contact B opened

close contact A = run

open contact A = stop

push contact B = reset

A

A

A

B

B

Push A = start

Push A = stop

Push B = reset

Stop

Start

Reset

GND

A

B

C

Stop

Start

Reset

GND

A

B

Push A = reset and start

Push B = stop

(push B again = start)

Push B = start

Push A = stop

Push C = reset

note A may close while B

is shut

B may open while A is shut

9.3.- RUN TIME ALARM SETTING

The alarm is a 4 decade alarm only. On the 6 decade clock, the alarm setting is for hours and minutes only and

on the 4 decade clock the alarm point can be for either hours and minutes or minutes and seconds.

Displaying or setting of the alarm point can only be done when the unit is displaying the run time and is not

running.

The same three contact inputs are used for setting the alarm point and for adjusting the real time clock, but their

functions are different.

To display the alarm set point, hold the SECONDS input (pin 13) to GND. Once the alarm point is displayed, the

value can be changed by contact closure between GND and the following terminals :

Seconds ........................... view/adjust alarm point ( hold to GND).

Minutes ............................ increment seconds ( or minutes).

Hours ............................... increment minutes ( or hours).

Hours and Minutes .......... together reset alarm to zero

9.4.- SERIAL DATA OUTPUT

The unit incorporates and RS422 level serial ASCII output to allow master/slave clock setups in conjunction with

serial ASCII remote displays.

Details of the serial output to be found in paragraph 5.

Note the line should be terminated to prevent noise pickup if the clock is not transmitting data.

10.- CONFIGURATION

10.1.- POWER SELECTION

See the rear label for power requirements. Power supply selection must be done by suitable qualified

personnel or by the local distributor. Contact factory or your local distributor for instructions.

10.2.- INSTRUMENT CONFIGURATION

To change the instrument configuration, the rear panel of the instrument needs only to be removed to gain

access to the internal DIP switches and jumpers located on the control board.

Be sure that the instrument is disconnected from any power supply before removing the rear panel.