Operating principle, Lvr300 series sensor overview programming overview, Terminal assignment – Omega Vehicle Security LVR300 User Manual

Page 3

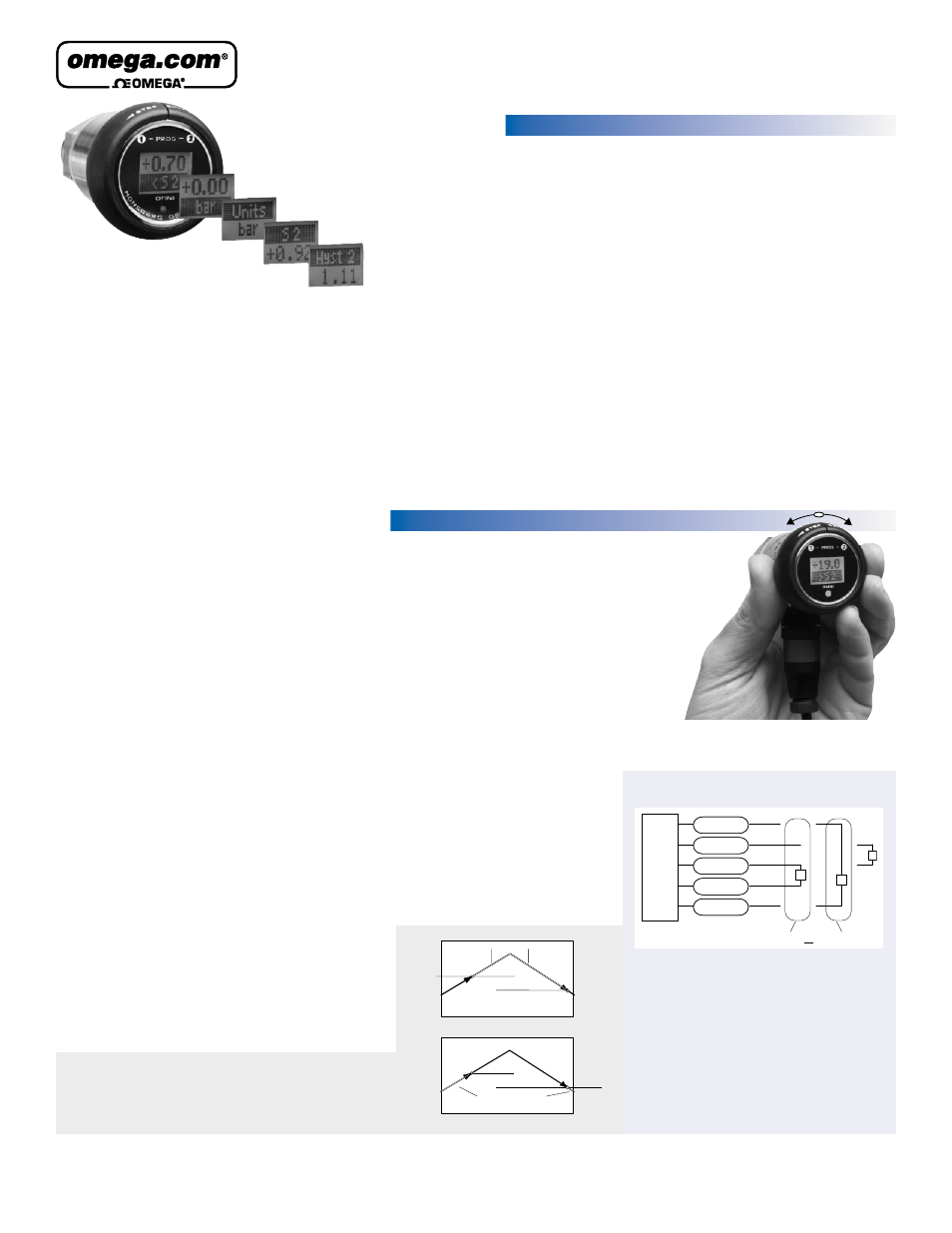

The LVR300 Series’ programming ring can be rotated from the Neutral center position to

Position 1 and Position 2. The following actions are possible:

A – Display of parameters with Position 1

(simultaneous display of the set parameters) –

Turn the programming ring left to Position 1 to begin cycling through these programming

parameters: Switching points S1 and S2, Hysteresis direction of S1 and S2,

Hysteresis Hyst 1 and Hyst 2, Code (allows editing of additional parameters),

Filter, Units, Output, 4 mA Value and 20 mA value. See following pages for

detailed programming instructions.

B – Editing with Position 2

Turn the programming ring to the right to Position 2 and a flashing cursor

appears showing the position to be changed. With repeated turning to

Position 2, the values are increased. By turning to Position 1, you obtain

the next position. Each position can be edited in this way. If there is no

action within 5 seconds, the device returns to the normal display sec-

tion without the change being accepted, and you will have to cycle

through the program again.

C – Saving the change with Position 1

Turning one time toward Position 1 after quitting the last value signifies

acceptance of the change.

Programming protection:

The programming ring can be pulled off,

inverted and replaced. This will prevent further

programming resulting from turning the ring in

either direction.

The complete LVR300 Series Sensor is designed to be a self-contained continuous level sen-

sor and control, requiring only a power source. A 16-bit microcontroller with a 14-bit A/D

converter and a 12-bit D/A converter provides the necessary processing speed and

measurement accuracy. The signal is displayed with units using a back-lit LCD

graphical display and converted to a 4-20 mA signal. Two switch points

with either a positive or negative output can be programmed over the com-

plete range.

The switching point hysteresis can be set separately in value and direction

(minimum/maximum switching value). Upward and downward crossings of switching points and error messages are

shown in the display with a flashing red LED that is easily visible from a distance.

Other parameters can be changed using codes, including: signal filter; selectable unit (inch, cm) includes automatic con-

version of the values; selectable 0-20 mA or 4-20 mA output; value assignment of 4-20 mA (setting of zero point and

span). The complete housing can be rotated around the mechanical connection so that the correct reading position can be

set after mounting (installation).

This LVR300 Series is very easy to use, as dialog messages are displayed for the user. It can even be set when wearing

protective gloves, if necessary.

Operating Principle

© Copyright Omega Engineering Inc. – 4/05

All specifications are subject to change without notice.

LVR300 Series Sensor Overview

Programming Overview

Value

S1 max.

Alarm range

Hyst 1

Time

Value

S1 min.

Time

Hyst 1

Alarm range

Terminal Assignment

The switch points are automatically chang-

ing to positive or negative, depending on

your interface.

Mating Connector

M12 x 1, 5-position female, shielded, straight

or

M12 x 1, 5-position female, shielded, right angle

Sources: Hirschmann, Binder,

rde Connectors & Cables or

comparable connector

S2

S1

24 to 30 VDC

0 V

4-20 mA

LVR

Sensor

white

brown

gray

black

blue

z

z

Z = load

1

2

3

4

5

z

or

NPN

Exam ple: PNP

Programming Ring turns from

Position 1 to Position 2

Example of hysteresis setting:

Examples with S1 as maximum switching point

and as minimum switching point: