Raypak 514-824 User Manual

Page 13

AUTOMATIC CHLORINATORS AND CHEMICAL FEED-

ERS

All chemicals must be introduced and completely

diluted into the pool or spa water before being circulated

through the heater. Do not place chlorine tablets or

bromine sticks in the skimmer. High chemical concen-

trations will result when the pump is not running (i.e.

overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical back-

up into the heater when the pump is shut off.

NOTE: High chemical concentrates from feeders and

chlorinators that are out of adjustment will cause very

rapid corrosion to the heat exchanger in the heaters.

Such damage is not covered under the warranty.

UNITHERM GOVERNOR OPERATION

The patented Unitherm Governor is a thermostatic

mixing valve specifically designed to maintain constant

heater internal temperature between 105°F to 115°F

despite continually changing flow rated from the filter and

changing pool temperatures. This narrow range is

needed to prevent damaging condensation on the burn-

ers which will occur if the heater runs for any length of

time below 100°F. It is also needed to inhibit scale

formation in the tubes by maintaining temperatures well

below accelerated scaling temperatures.

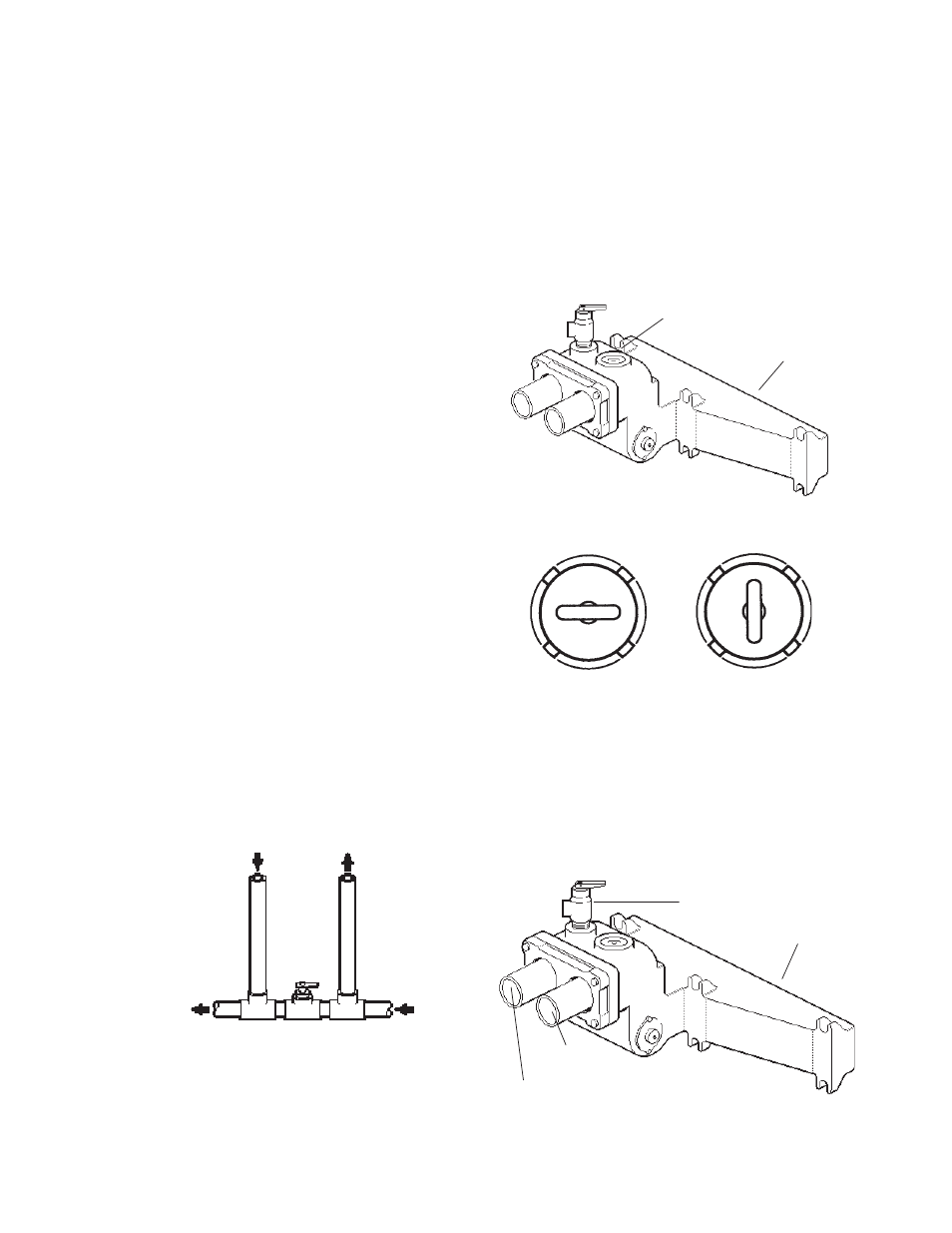

EXTERNAL AUXILIARY BYPASS VALVE

(Where Required)

An auxiliary bypass valve should be used when flow

rates exceed 115 GPM (usually a high performance

pump size larger than two HP will exceed this flow rate).

This valve is required to complement the function of the

automatic bypass valve, particularly when starting the

heater in winter or early spring when the spa or pool

temperature is down below 55°F. It also serves to

eliminate needless pressure drop through the heat and

accompanying reduction in the flow rate to the spa jets,

etcetera.

FROM

TO

HEATER

HEATER

TO POOL

FROM

POOL

Fig. # 8150.0

AUXILIARY BYPASS VALVE ADJUSTMENT

13

To set bypass: with clean filter, adjustment is made

by feeling the inlet and outlet pipes at the heater. Outlet

pipes should be slightly warmer than inlet and comfortable

to the touch. If pipe is hot, close bypass; if cold open

bypass.

The heater is also equipped with a manual bypass

built into the header. This is in addition to the automatic

bypass valve. This may be used with flow rates up to 120

GPM and adjusted as below.

NOTE: Sooting or liming caused by improper bypass

adjustment voids the warranty

BYPASS VALVE

INLET/OUTLET

HEADER

Fig. # 8223.0

MANUAL BYPASS ADJUSTMENT

OPEN POSITION

CLOSED POSITION

Fig. # 8222.0

PRESSURE RELIEF VALVE INSTALLATION

To conform to local building codes, it may be

necessary to install a pressure relief valve. A 3/4”

pressure relief valve having a capacity equal to BTU/HR

output of the model to be installed is recommended for this

appliance.

A 3/4” NPT connection is provided in the inlet/outlet

header for installation of a pressure relief valve. The valve

shall be installed in a vertical position.

PRESSURE RELIEF VALVE

INLET/OUTLET HEADER

INLET

OUTLET

Fig. # 8223.0