Raypak 514-824 User Manual

Page 12

PIPE SIZING FOR GAS CONNECTIONS

MAXIMUM EQUIVALENT PIPE LENGTH

Natural gas 1000 BTU/Ft .60 Specific Gravity @ 0.5” W.C. Pressure Drop

Propane Gas 2500 BTU/Ft 1.53 Specific Gravity @ 0.6” W.C. Pressure Drop

1/2”

1”

1-1/4” 1-1/2” 2” 2-1/2”

N P N P N P N P N P N P

514 - 10 15 35 65 150 130

360 500 - -

-

624 - - 10 25 45 100 95

250 340 - -

-

724 - - - 20 35 80 75

180 260 600 -

-

824 - - - 15 25 60 55

130 185 480 500 -

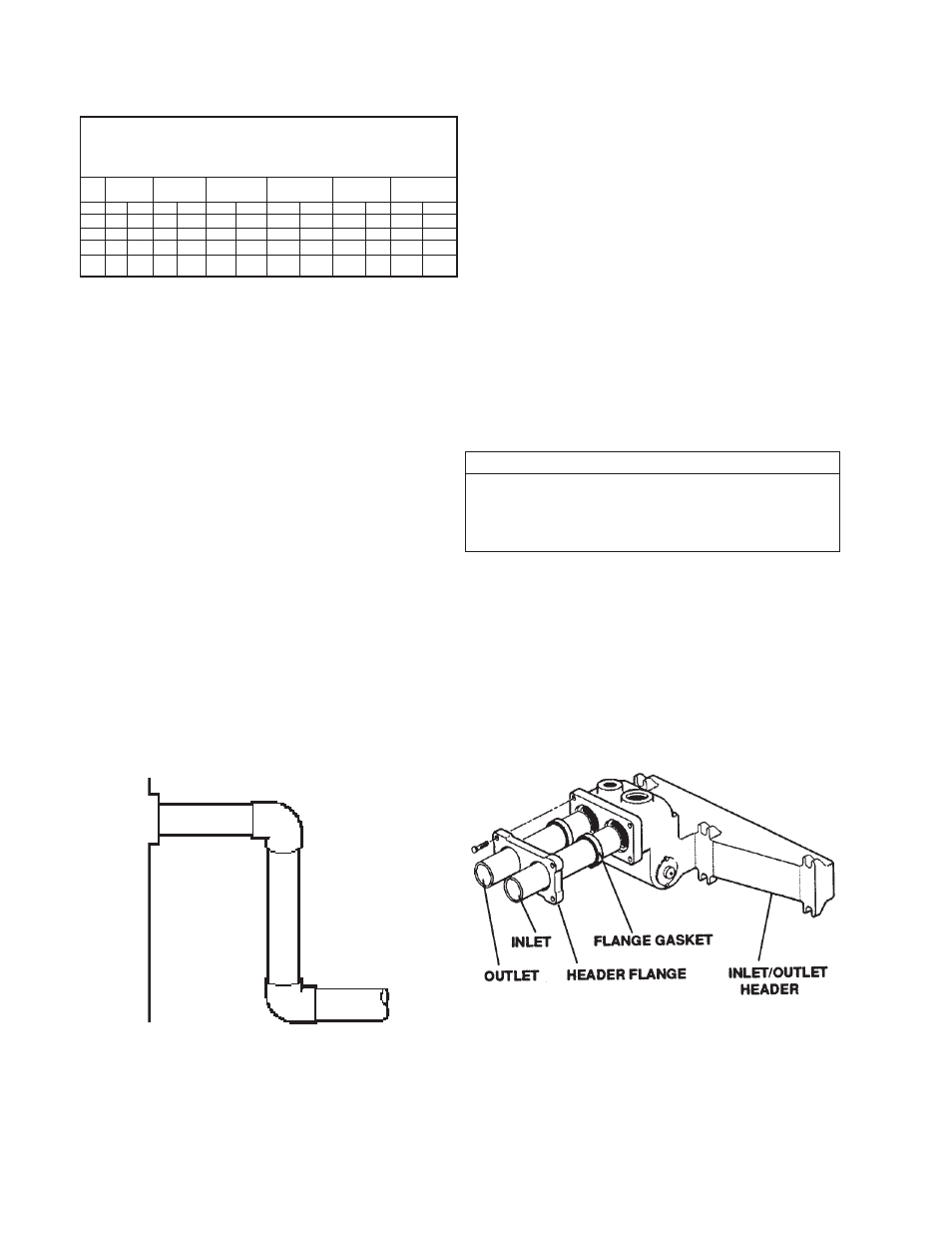

PLUMBING FOR WATER CONNECTIONS

LOCATION

The heater requires water flow and positive pressure

to fire and operate properly. It must therefore be installed

downstream of the discharge side of the filter pump. A

typical installation is plumbed as follows:

1. The inlet side of the filter is plumbed directly to

the discharge side of the filter pump;

2. The outlet side of the filter is then plumbed to

the inlet of the heater; and

3. The outlet of the heater is plumbed to the return

line to the pool or spa. The pump, filter and

heater are thus plumbed in series.

Heater must be located so that any water leaks will not

damage the structure of adjacent area. High temperature

plastic pipe (CPVC) may be connected directly into the

heater if local codes permit and if controls operate the

pump for at least fifteen minutes after the heater is turned

off.

CAUTION: NEVER install PVC directly into heater.

Four feet of copper or high temperature pipe and two

elbows are required between the heater and the PVC

connections

Fig. #8129.0

12

When local codes permit the use of less than four feet

high temperature piping or two elbows, provisions should

be made to always shut the heater off a minimum of 15

minutes prior to pump shut down in order to carry away

residual heat and prevent damage to the low temperature

piping. A fireman switch included in the time clock may

be used for this purpose with instruction not to override

this sequence manually. See wiring diagram section for

electrical hookup location of the fireman switch in the

electrical circuit.

NOTE: 1. When 2” piping is used into the heater, this

piping must be anchored (copper) or screwed into the

flange (metal) if operating pressures above 30 PSI are

encountered.

2. Any restrictions between heater outlet and

pool will void the warranty.

FLOW RATES

MODEL

PIPE SIZE MIN. GPM

MAX. GPM

514

2”

60

120

624

2”

60

120

724

2”

60

120

824

2”

60

120

COMPANION FLANGE CONNECTIONS

DO NOT use petroleum base assembly fluids (such as

Petroleum Jelly or lubricating oil). If assembly tube is

required use a silicone base such as Armoral etc.

The inlet/outlet header flange accepts a 2” copper

tube as a slip connection directly into the header. The

flange is also thread for a 2” copper male threaded

adapter.

Fig. # 8221.0

3

3