Maintenance – RIDGID MS1250LZ1 User Manual

Page 31

31

Some areas will require infrequent lubrications. You will

need to apply:

Automotive oil directly to the slide bars.

Light oil or a pressurized light spray oil to the arm pivot

shaft.

Light oil or a pressurized light spray oil to the torsion

spring.

EXTENSION CORDS

The use of any extension cord will cause some loss of power.

To keep the loss to a minimum and to prevent tool overheat-

ing, use an extension cord that is heavy enough to carry the

current the tool will draw.

A wire gauge size (A.W.G.) of at least

14 is recommended for

an extension cord 25 feet or less in length. When working

outdoors, use an extension cord that is suitable for outdoor

use. The cord's jacket will be marked WA.

WARNING:

Keep extension cords away from the cutting area

and position the cord so that it will not get caught

on lumber, tools, etc., during cutting operation.

Failure to heed this warning may result in serious

personal injury.

CAUTION:

Check extension cords before each use. If dam-

aged, replace immediately. Never use tool with a

damaged cord since touching the damaged area

could cause electrical shock resulting in serious

injury.

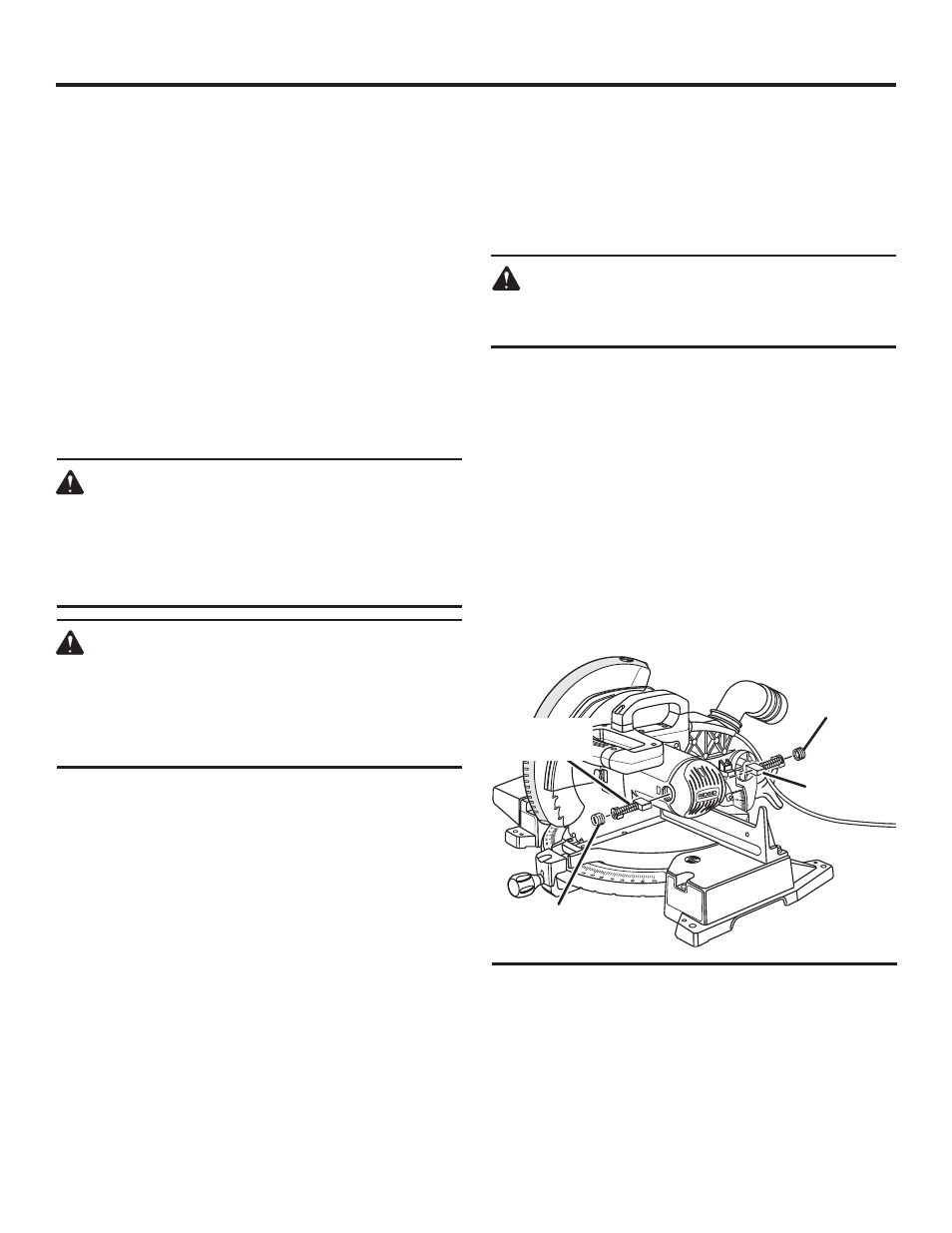

BRUSH REPLACEMENT

See Figure 37.

The saw has externally accessible brush assemblies that

should be periodically checked for wear.

Proceed as follows when replacement is required:

Unplug the saw.

WARNING:

Failure to unplug the saw could result in accidental

starting causing serious injury.

Remove brush cap with a screwdriver. Brush assembly is

spring loaded and will pop out when you remove brush

cap.

Remove brush assembly.

Check for wear. Replace both brushes when either has

less than 1/4 in. length of carbon remaining.

Do not re-

place one side without replacing the other.

Reassemble using new brush assemblies. Make sure

curvature of brush matches curvature of motor and that

brush moves freely in brush tube.

Make sure brush cap is oriented correctly (straight) and

replace.

Tighten brush cap securely.

Do not overtighten.

MAINTENANCE

®

BRUSH

CAP

Fig. 37

BRUSH

CAP

BRUSH

ASSEMBLY

BRUSH

ASSEMBLY