Raypak WH 0195A User Manual

Page 21

Normal Inspection Procedures

First and third month after initial start up and then on

an annual basis. If problems are found, refer to

Trouble Shooting Guide for additional directions.

1. Remove top of heater and inspect heat exchanger

for soot and examine venting system.

2. Remove rear header and inspect for scale

deposits.

*3. Inspect pilot and main burner flame and firing rate.

*4. Inspect and operate all controls and gas valve.

*5. Visually inspect system for water leaks.

*6. a.

Oil pump motor and bearing assembly, if oil

cups are provided.

b. Disconnect pump from header and check con-

dition of pump impeller. Check condition of

bearing by attempting to move impeller from

side to side. Replace any parts showing wear.

c. Check pump coupler for wear and vibration.

7. Check flow switch paddle (if provided).

8. Clean room air intake openings to assure ade-

quate flow of combustion and ventilation air.

9. Keep heater area clear and free from combustible

materials, gasoline, and other flammable vapors

and liquids.

*Should be checked monthly. (Takes approximately 15

minutes).

21

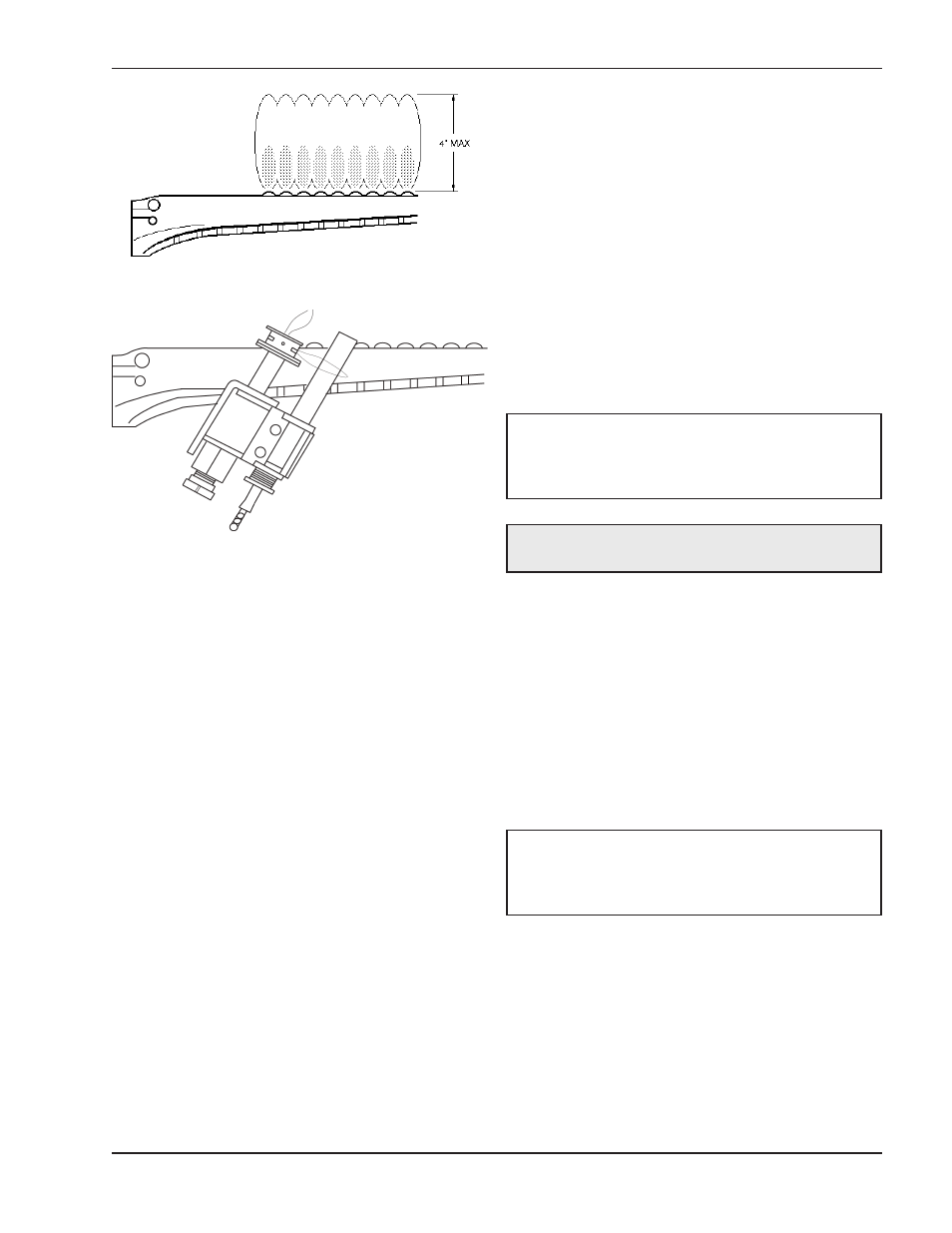

Fig. 16: Typical Main Burner Flame

Fig. 17: Pilot Burner Flame (STG Pilot Units)

Procedure for Cleaning Flue Gas

Passage Ways

Soot will clog areas behind fins and eventually cause

tube failure. Any sign of soot at base of burners or

around outer jacket indicates a need for cleaning.

1. Lift off draft hood and flue collector by removing

bolts and screws.

2. Remove "V" baffles from heat exchanger.

3. Remove burner tray, see Burner Drawer Removal.

4. Take garden hose and wash heat exchanger, mak-

ing sure soot is removed from between fins. (Avoid

excessive water against refractory).

5. Reassemble; when heater is fired, some steam

will form from wet refractory, which is normal.

Burner Drawer Removal

1. Shut off power and gas supply to the heater.

Disconnect union(s) and pilot tubing when present;

then loosen and remove burner hold down screws.

2. Disconnect wires at gas valve and slide burner

drawer out.

Main Burner and Orifice Removal

1. Remove screws and burner hold down bracket.

2. Lift burners from slotted spacer and slide from ori-

fices. Clean with a wire brush.

3. Orifices usually do not need to be replaced. To

clean, run either copper wire or wood through ori-

fice. Do not enlarge hole. To remove orifice, use a

socket wrench and remove the manifold. DO NOT

overtighten when reinstalling.

NOTE: In extreme cases it may be necessary to

remove the heat exchanger completely for cleaning.

The simplest method is steam cleaning at a local car

wash.

CAUTION: Soot is combustible. Exercise extreme

care. Do not wire brush.

NOTE: If the heat exchanger is sooted badly, the

burner hold down bracket and spacer can become

distorted from direct flame impingement and this

usually necessitates replacement of these parts.