Troubleshooting – Raypak HI DELTA 302B User Manual

Page 51

51

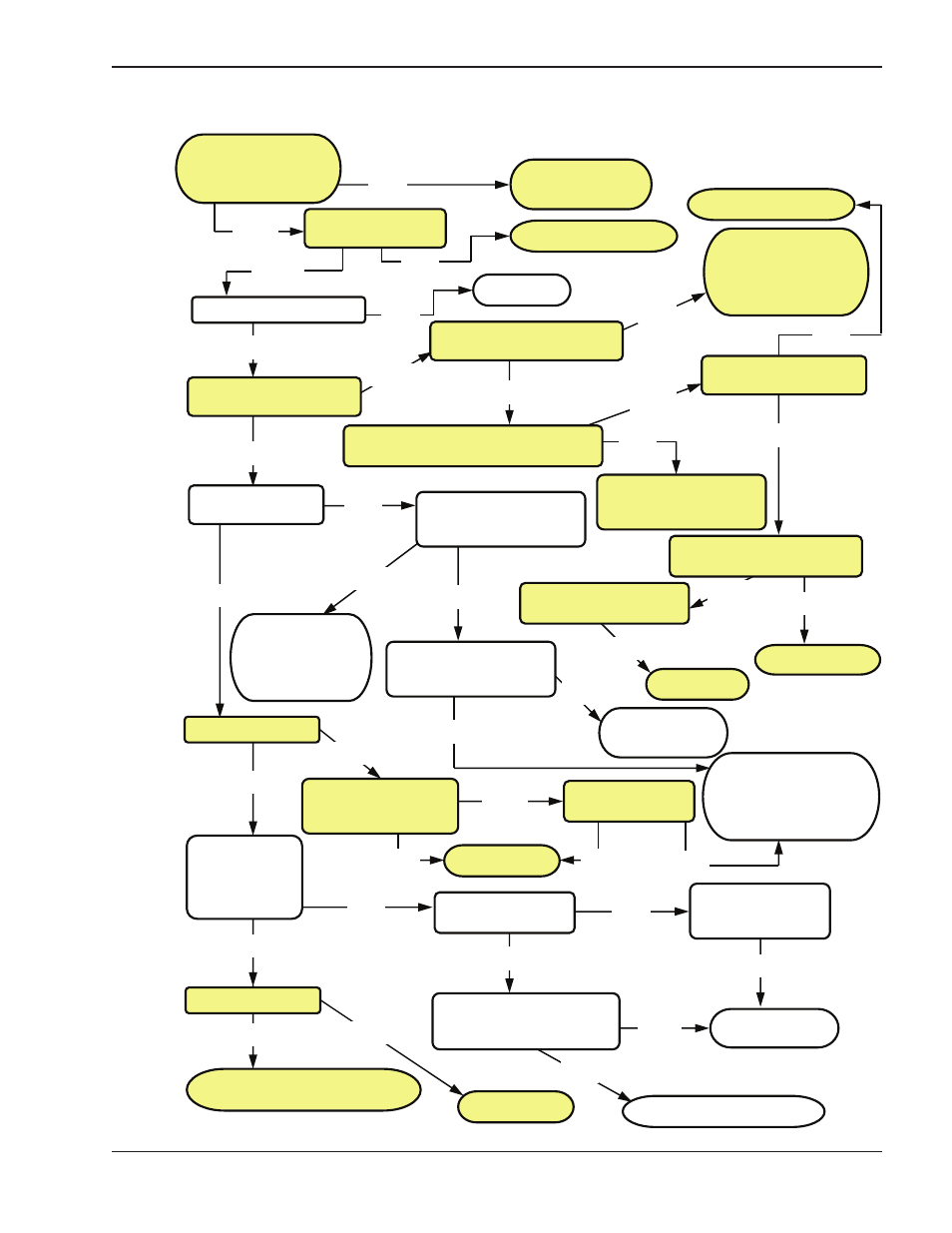

TROUBLESHOOTING

Ste p 7

Ste p 6

Ste p 5

Step 1

Step 2

Step 3

Step 4

Is there a Call For

Heat?

Is Disable j um p er intact? ( J1 )

Is there 120VAC at J8

Connecto r on the CPW board?

Do the combustion air

blowers come on?

Is 24VAC at present at TH (J3 & J12 on CPW

board and orange wire on ignition module)?

Check flow switch, all

connectors on CPW board

and controller.

Are the blower lights

illuminated?

Is air pressure switch(s) and

J2 of CPW board (N.O.)

p owered?

Does F2 on ignition module

have 120VAC?

Check the fan relay. Is there

120VAC at K3 relay?

Is there continuity from the

fan relay to fan(s)?

Does air pressure switch(s)

have correct pressure?

( 1.4” W.C. )

Does i g niter p rove?

Check Amp draw during

heat-up for greater than

3.1 Am p s.

Is air switch

bouncing?

Call our Technical Service Department

1-805-278-5300

Replace gas valve

Are the gas valve

settings correct?

Re p lace fan rela y

Re p lace fan

Replace air

p ressure switch

Correct the air settings or

you may have to clean

burners, heat exchanger

and/or air filter.

NO

Check the switch

and/or line voltage

YES

Does the power switch

provide power to the

control panel?

Unit is in standby mode.

Reattach.

YES

NO

NO

YES

YES

NO

Replace ignition module

Check all safety limit

devices and voltage from

the transformer to J10 on

CPW board.

NO

NO

YES

YES

NO

YES

NO

YES

Is 24VAC at PS on

ignition module? Is

connecting plug

secure?

NO

YES

YES

NO

NO

YES

NO

YES

YES

NO

NO

YES

Is the flame

sensor signal to

the ignition

module greater

than 1 uA DC?

YES

NO

NO

The unit is oka y

YES

YES

NO

Readjust to 3.5” W.C.

gas.

Is the unit running?

NO

YES

Replace HSI

Is the unit runnin g ?

NO

YES

Clean or replace flame senso r

Is static and dynamic inlet

manifold gas pressure correct?

Is downdraft present?