Electrical power connections – Raypak HI DELTA 302B User Manual

Page 22

22

6. Reinstall the pipe cap on the left-hand end of the

main gas line.

7. Remove plastic cap from the right-hand side panel

and reinstall into the standard main gas opening

located on the left-hand side of the heater.

8. Remove the rubber grommet from the left-hand-

side panel and reinstall into the standard main gas

opening, located on the right-hand side of the

heater.

9. Install a coupling, nipple, union and sediment trap

onto the right-hand end of the main gas line and

then install the gas line, making sure that a manu-

al shut-off valve has been installed within 10 ft of

the heater.

10. Replace the left and right front panels on the

heater.

Gas Supply Pressure

A minimum of 5.0 in. WC and a maximum of 10.5 in.

WC upstream gas pressure is required under load and

no-load conditions for natural gas. A minimum of 11.0

in. WC and a maximum of 13.0 in. WC is required for

propane gas. The gas pressure regulator(s) supplied

on the heater is for low-pressure service. If upstream

pressure exceeds 14.0 in. WC, an intermediate gas

pressure regulator, of the lockup type, must be

installed.

When connecting additional gas utilization equipment

to the gas piping system, the existing piping must be

checked to determine if it has adequate capacity for

the combined load.

The gas valve pressure regulator(s) on the heater are

nominally preset at 3.5 in. WC for natural gas, and

10.5 in. WC for propane gas. The pressure at the gas

valve outlet tap, measured with a manometer, while in

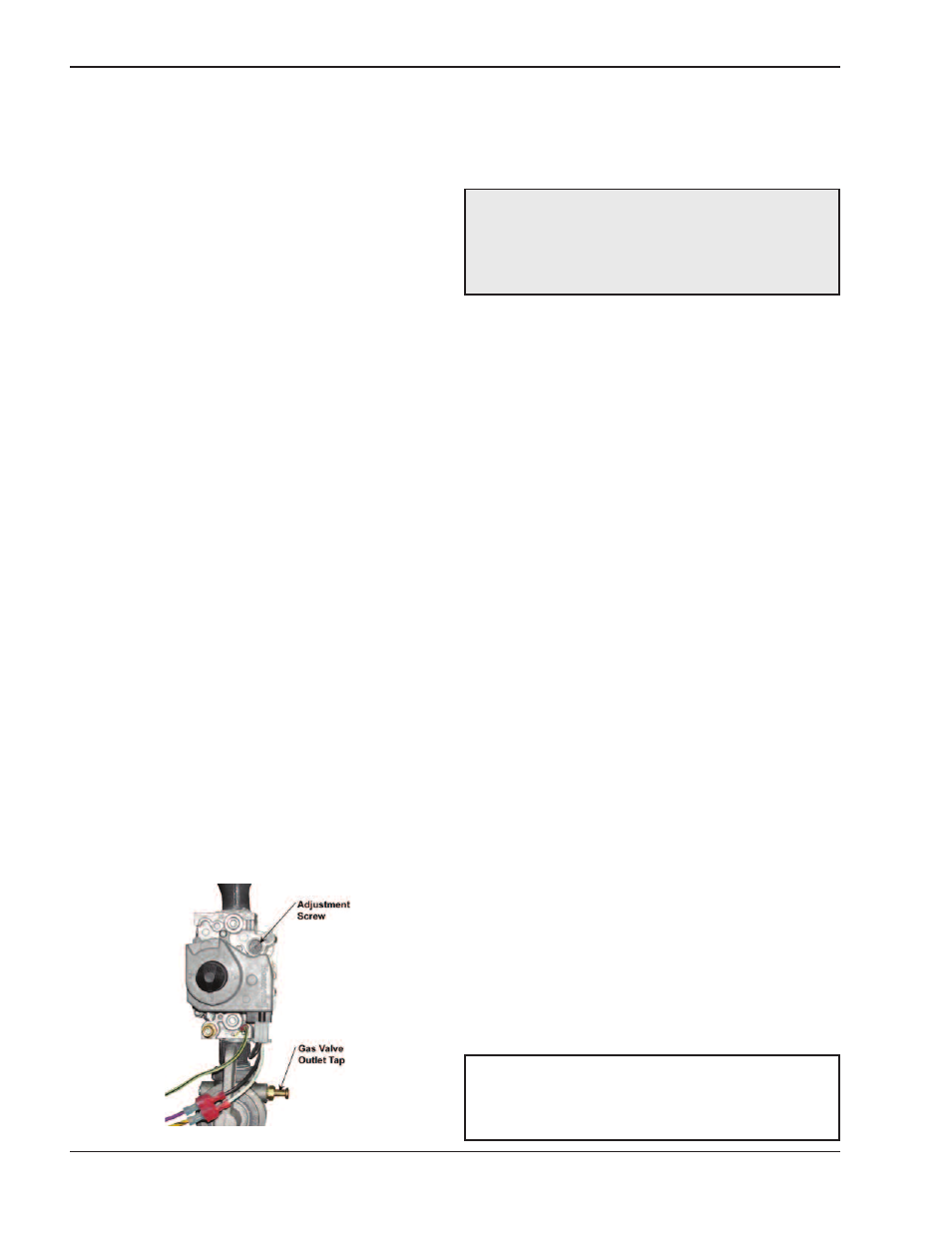

Fig. 17: Gas Valve

operation should be 3.5 ± 0.1 in. WC for natural gas

and 10.5 in. ± 0.1 in. WC for propane gas. If an adjust-

ment is needed, remove the adjustment screw cover

and turn the adjustment screw clockwise to increase

pressure or counter-clockwise to lower pressure.

Electrical Power Connections

Installations must follow these codes:

•

National Electrical Code and any other national,

state, provincial or local codes or regulations hav-

ing jurisdiction.

•

Safety wiring must be NEC Class 1.

•

Heater must be electrically grounded as required

by the NEC.

•

In Canada, CSA C22. 1 C.E.C. Part 1.

The heater is wired for 120 VAC, 8 amps in its basic

configuration. Additional options may increase the

amp draw of the unit. The voltage is indicated on the

tie-in leads. Consult the wiring dia-gram shipped with

the heater in the instruction packet. The remote tank

control stat, thermostat, or electronic heater control (as

applicable) may be connected to the stage selector

terminal (See wiring diagram). 24 VAC is supplied to

this connection through the heater trans-former. DO

NOT attach any voltage to the stage selector termi-

nals. Before starting the heater check to ensure

proper voltage to the heater and pump.

Install a separate disconnect means for each load.

Use appropriately sized wire as defined by NEC, CSA

and/or local code. All primary wiring should be at least

125% of minimum rating.

If any of the original wire as supplied with the heater

must be replaced, it must be replaced with 105°C wire

or its equivalent.

Field-Connected Controllers

It is strongly recommended that all individually-pow-

ered control modules and the heater should be

supplied from the same power source.

NOTE: Field-supplied isolation relays should be

installed when field-connected controllers are

mounted more than 50 equivalent feet (18 Ga) from

heater.

CAUTION: For proper operation, no more than a

30% drop in gas supply pressure from no-load to full-

load conditions is acceptable. Under no

circumstances should the pressure be outside the

listed operational range.