Safety instructions – Ryobi 227RJ User Manual

Page 7

English –

7

3. Cutting

attachment guard

• Ensure that the spray

guard is undamaged and

is not cracked.

• Replace the guard if it

has been exposed to

impact or is cracked.

• Always use the prescribed

blade an guard

combination, see chapter

"Technical data".

SAFETY INSTRUCTIONS

Control, maintenance and service of

the machine‘s safety equipment

IMPORTANT INFORMATION

•

All service and repairs to the machine require

special training.

•

This applies especially to the machine‘s safety

equipment. If the machine does not meet any of

the controls listed below you should contact your

service workshop.

•

The purchase of one of our products

guarantees that professional repair and servicing

will be carried out on it. If the point of purchase is

not one of our servicing dealers, please ask for

details of the closest service workshop.

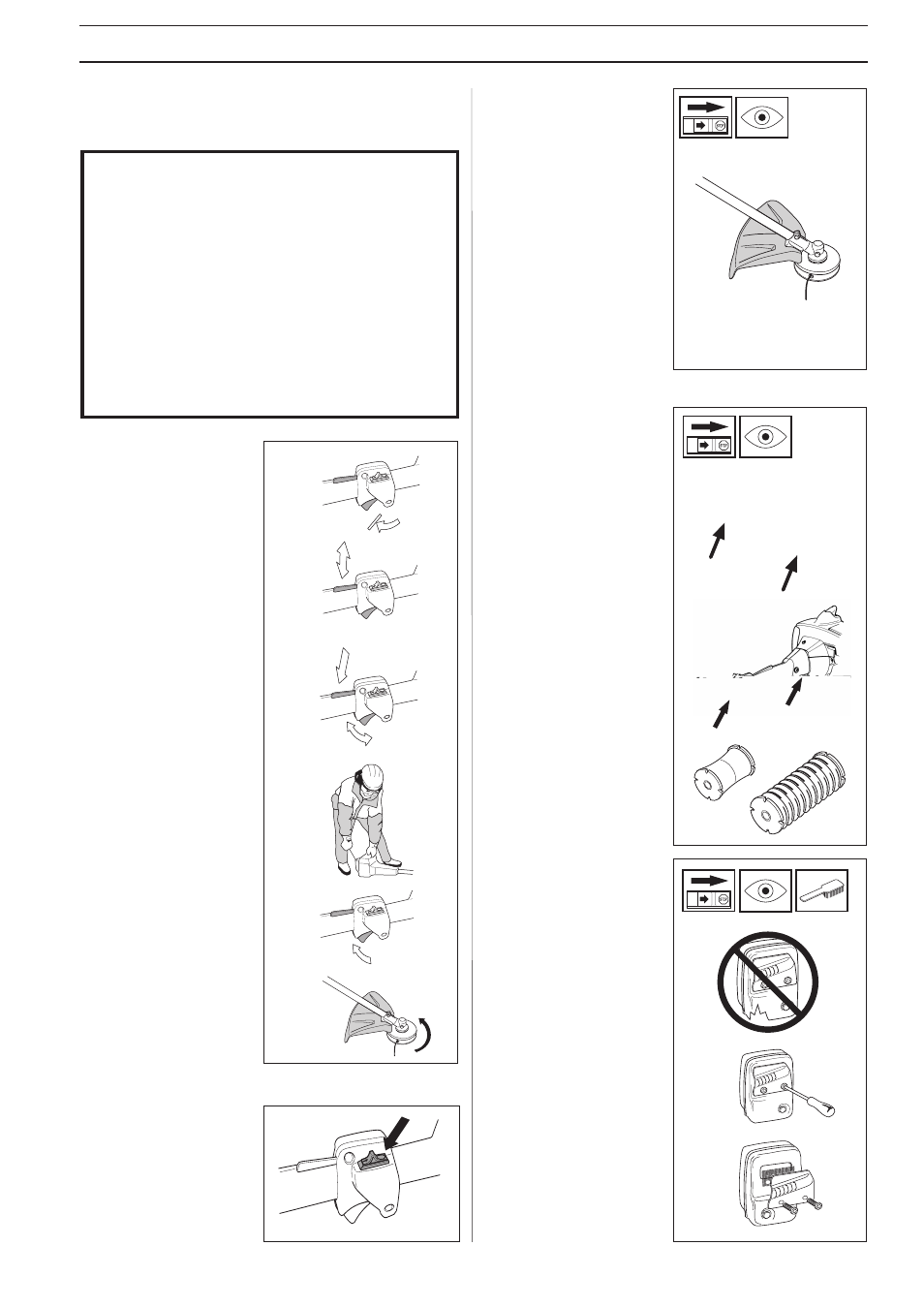

1. Throttle trigger

lock

• Check that the throttle is

locked in the “idling

position“ when the

throttle trigger lock is in

its original position.

• Press in the throttle

trigger lock and make sure

it returns to its original

position when released.

• Ensure that the throttle

and throttle trigger lock

move easily and that their

return spring systems

function.

• See section "Start". Start

the machine and apply

full throttle. Release the

throttle and check that the

cutting equipment stops

and remains at a standstill.

If the cutting equipment

rotates with the throttle in

the idling position then

the carburettor‘s idling

setting must be checked.

See chapter

“Maintenance“.

2. Stop switch

• Start the engine and make

sure that the engine stops

when the stop switch is

moved to the stop

position.

4. Vibration

damping system

• Check the vibration

damping element

regularly for material

cracks and distortion.

• Check that the vibration

damping element is

undamaged and securely

attached.

#

5. Muffler

1.Never use a machine that

has a defective muffler.

2.Check regularly that the

muffler is secure.

3.If your muffler is fitted

with a spark arrest screen

then it should be cleaned

regularly. A blocked

screen leads to the engine

overheating with serious

damage as a result. Never

use a muffler with a

defective spark arrest

screen.