Operation – RIDGID R3202 User Manual

Page 16

16

56

0

56

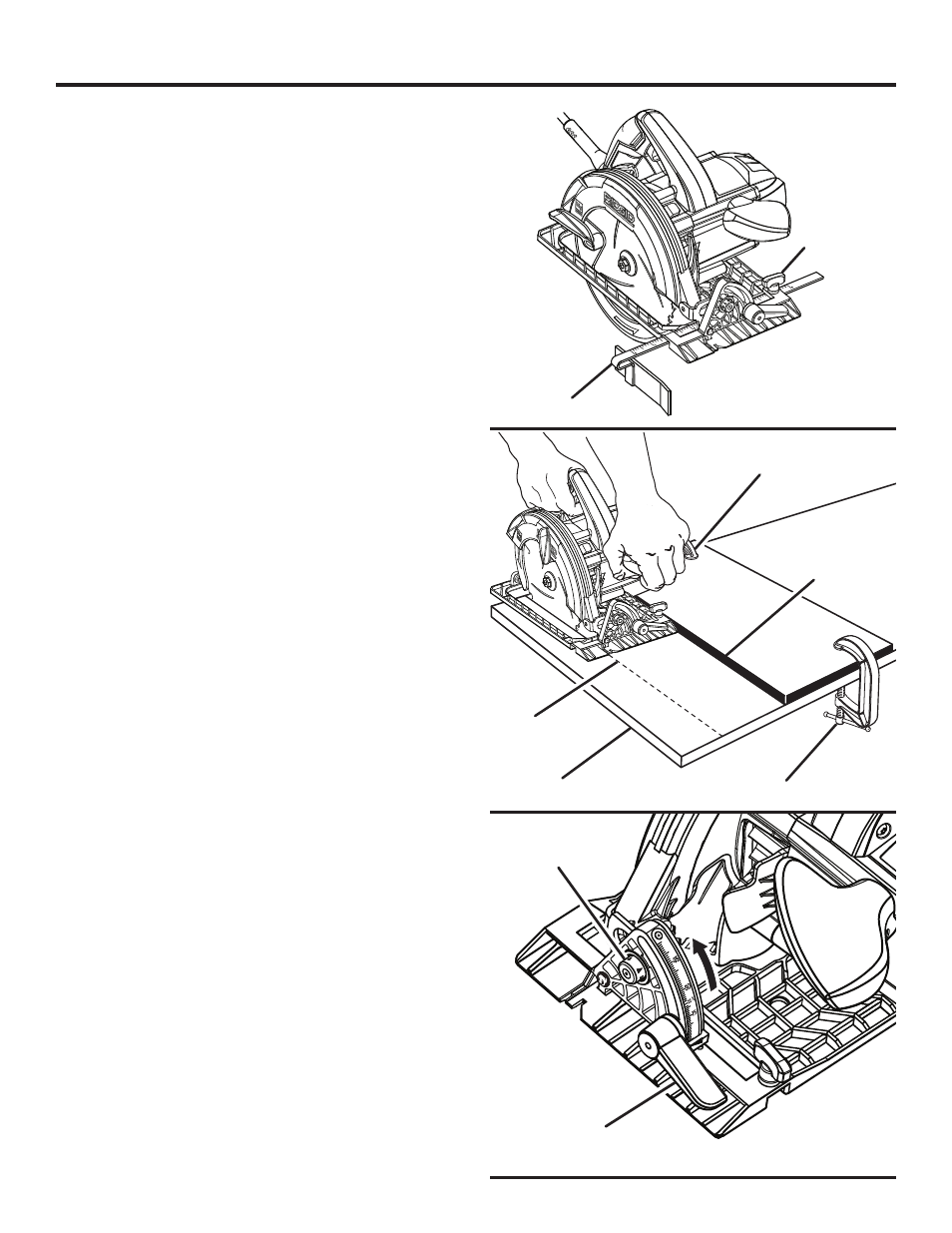

RIP CUTTING

See Figures 15 - 16.

Use a guide when making long or wide rip cuts with the

saw.

To rip cut using optional edge guide:

Slide the edge guide into the slot.

Adjust the guide so that the "0" on the guide is aligned

with the edge of your workpiece.

Secure the guide with the lock screw provided with the

saw.

Secure the workpiece.

Position the face of the edge guide firmly against the edge

of workpiece.

NOTE: The guiding edge of the workpiece must be

straight for your cut to be straight. Use caution to prevent

the blade from binding in the cut.

Saw along workpiece keeping guide firmly against edge

to achieve a straight rip cut.

To rip cut using a straight edge:

Secure the workpiece.

Clamp a straight edge to the workpiece using

C-clamps.

Saw along the straight edge to achieve a straight rip

cut.

NOTE: Do not bind the blade in the cut.

BEVEL CUTTING

See Figures 17 - 19.

To make the best possible cut, follow these helpful hints:

Align the line of cut with the inner blade guide notch on

the base when making 45° bevel cuts.

Make a trial cut in scrap material along a guideline to

determine how much you should offset the guideline on

the cutting material.

Adjust the angle of cut to any desired setting between

zero and 56°. Positive stops are located at 0°, 45° and 56°.

Refer to

Adjusting Bevel Setting later in this manual.

NOTE: Push the positive 56° stop button in while raising

the motor housing to set the bevel setting above 45° and

up to 56°.

Adjusting Bevel Setting:

Unplug the saw.

Pull the bevel adjustment lever upward until the motor

housing moves freely.

Rotate motor housing end of saw until you reach the

desired angle setting on bevel scale.

NOTE: Positive stops are located at 0°, 45° and 56°.

Push the positive 56° stop button in while raising the

motor housing to set the bevel setting above 45° and up

to 56°.

Push downward on the bevel adjustment lever until the

motor housing is securely locked in place.

OPERATION

Fig. 16

Fig. 15

EDGE GUIDE

STRAIGHT

EDGE

C-CLAMP

wORKPIECE

GUIDELINE

BEvEL

ADJUSTMENT

LEvER

56° BEvEL

BUTTON

Fig. 17

C-CLAMP

LOCK SCREw