Installation, Gas pipe pressure testing, Door installation (packaged separately) – Regency U37-NG NATURAL GAS User Manual

Page 19

U37 Regency ULTIMATE Rear Vent Direct Vent Freestanding Gas Heater

19

INSTALLATION

GAS PIPE PRESSURE TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa). Disconnect piping from valve at pres-

sures over 1/2 psig.

The manifold pressure is controlled by a reg-

ulator built into the gas control, and should be

checked at the pressure test point.

Note: To properly check gas pressure,

both inlet and manifold pressures

should be checked using the valve

pressure ports on the valve.

1) Make sure the valve is in the "OFF" position.

2) Loosen the "IN" and/or "OUT" pressure

tap(s), turning counterclockwise with a 1/

8" wide flat screwdriver.

3) Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" ID hose.

4) Light the pilot and turn the valve to "ON"

position. Read manometer.

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specified on the safety

label.

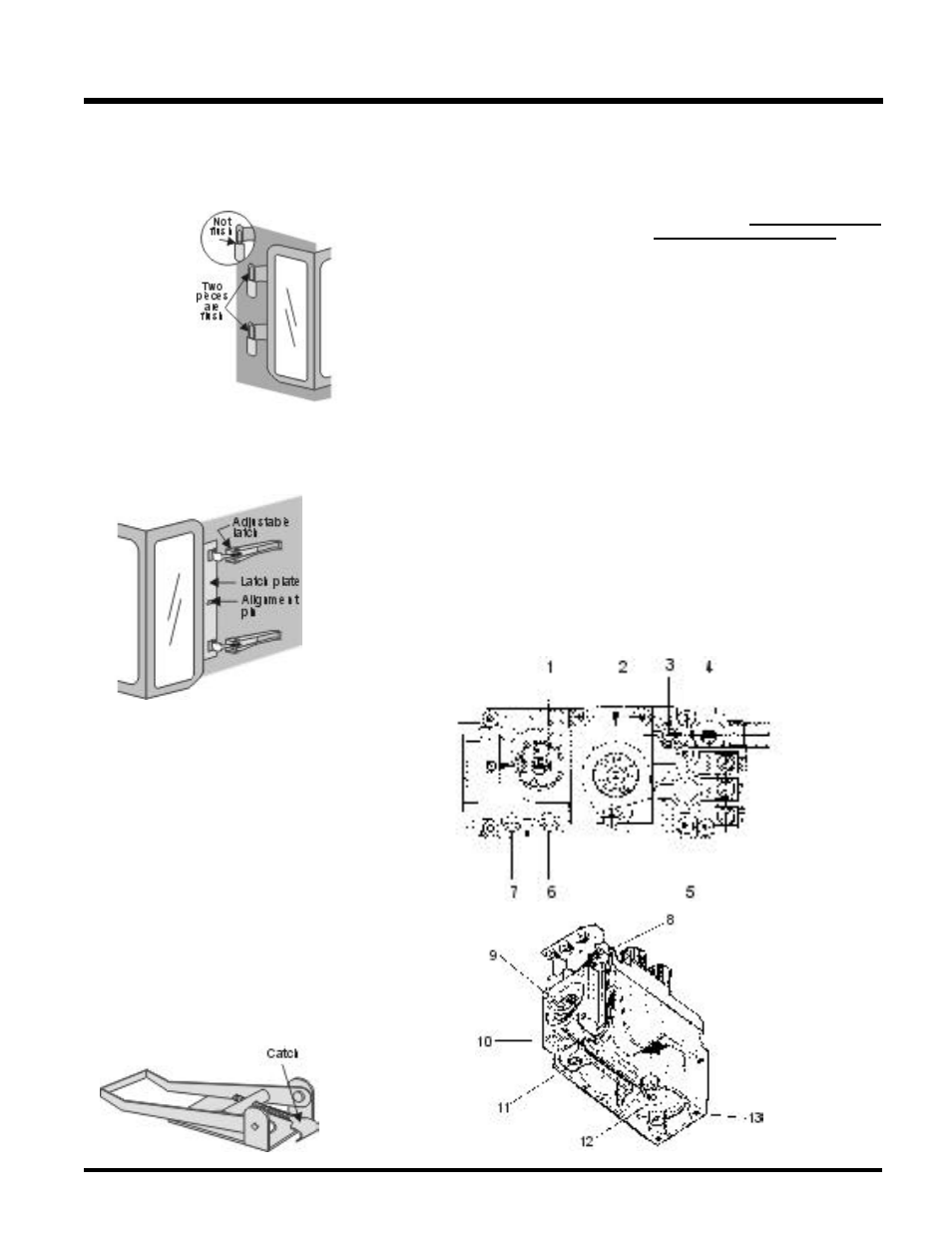

Diagram 2

4) The latches should already be at the

proper setting. If they are too hard or too

easy to close, you may want to adjust

them by loosening the locking nut and

turning the latch catch. See diagram 3.

5) Remove the blue plastic protective coat-

ing from the glass.

6) Test the seal around the door by placing

a piece of paper between the unit and the

door, close the door and try to pull the

paper out. If it slips out easily, then the

door is not properly sealed. Tighten or

loosen the latch by turning the latch catch

inward or outward. See diagram 3.

Note: The door latch may require ad-

justment as the door gasket ma-

terial compresses after a few

fires and after glass replace-

ment. Turn the latch catch in-

ward or outward.

Diagram 1

DOOR INSTALLATION

(Packaged Separately)

1) Open the two side panels.

2) Slide the door

o n t o t h e t w o

hinge pins mak-

ing sure the

two pieces are

flush together.

See diagram

1.

3) Close the door. The

latch plate must be

centered around the

alignment pin. See dia-

gram 2. If the latch plate

interferes with the cor-

ner of the stove you may

want to angle the plate

slightly so the door clos-

es easier.

6) When finished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8"

flat screwdriver. Note: Screw should be

snug, but do not over tighten

Valve Description

1) Gas cock knob

2) Manual high/low adjustment

3) Pilot Adjustment

4) Thermocouple Connection

5) Main Operator

6) Outlet Pressure Tap (Manifold Pressure)

7) Inlet Pressure Tap (Supply Pressure)

8) Pilot Outlet

9) Main Gas Outlet

10) Flange Securing Screw Holes

11) Alternative TC Connection Point

12) Thermoelectric Unit

13) Additional Valve Mounting Hole

Diagram 3