Adjustments – RIDGID R4516 User Manual

Page 35

35

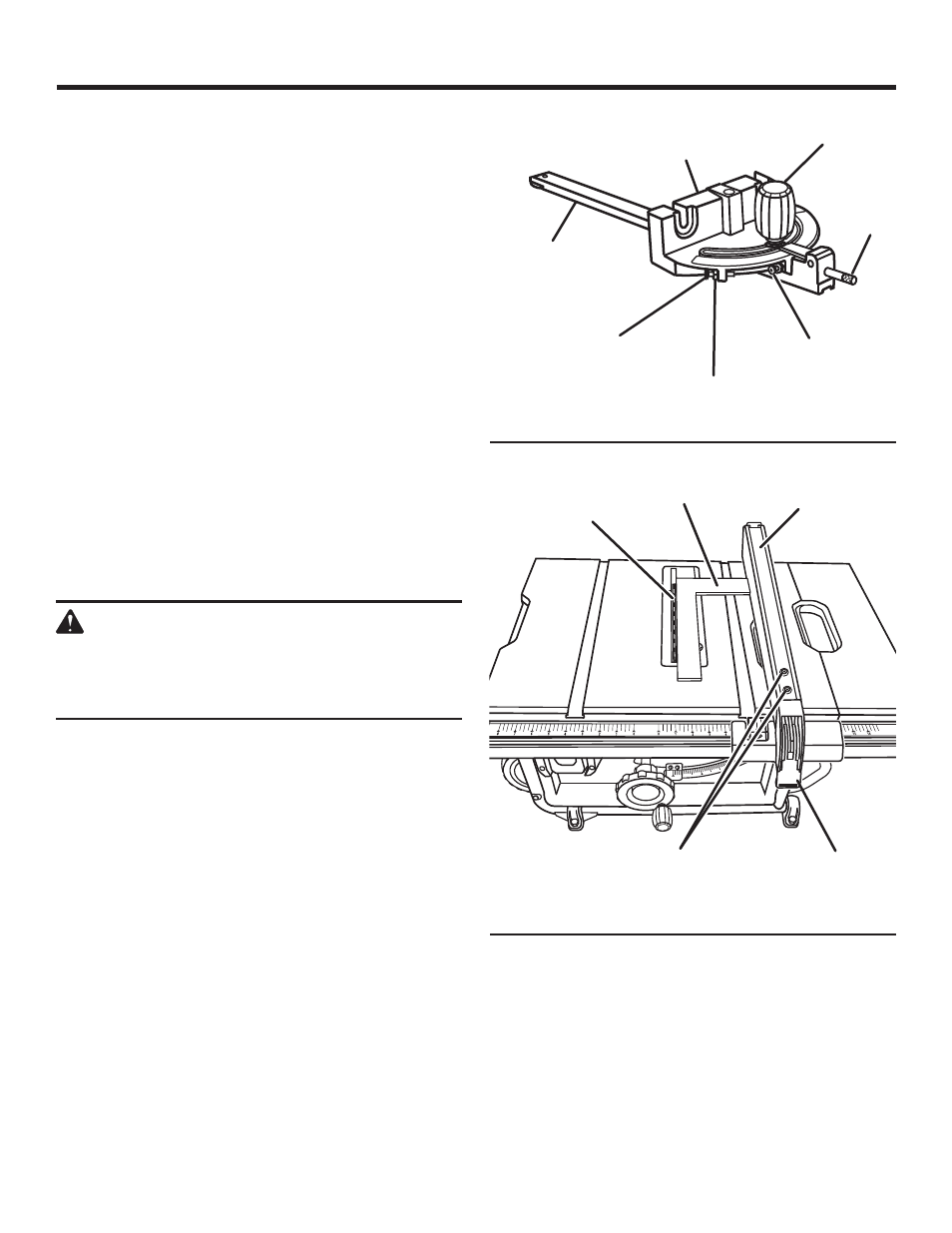

adjustments

bLAdE

RIp FENCE

LOCKING

LEVER

SCREWS

LOCK

Nut

KNOb

MItER

GAuGE bASE

45° AdJuStAbLE

StOp SCREW

0° AdJuStAbLE

StOp SCREW

MItER

GAuGE ROd

tO adjust the mIteR GauGe

See Figure 47.

You can set the miter gauge at 0° and plus or minus 45° with

the miter gauge stop pin and adjustable stop screws.

nOte:

The miter gauge provides close accuracy in

angled cuts. For very close tolerances, test cuts are

recommended.

Loosen knob and pull out on stop pin to rotate miter

gauge base past stop screws.

Loosen the lock nut of the 0° stop screw at the stop pin

with a 8 mm wrench.

Place a 90° square against the miter gauge rod and the

miter gauge base.

If the rod is not square, loosen the knob, adjust the rod,

and tighten the knob.

Adjust the 0° stop screw until it rests against the stop

pin.

Adjust the plus and minus 45° stop screws using a 45°

triangle and the steps above.

tO checK the alIGnment OF the RIp

Fence tO the blade

See Figure 48.

WaRnInG:

To reduce the risk of injury, always make sure the

rip fence is parallel to the blade before beginning

any operation.

Unplug the saw.

Raise the locking lever to permit the rip fence to be

moved.

Place a framing square beside the blade and move the

rip fence up to the square. Take the dimension on the rip

scale.

Move the fence back and turn the framing square 180°

to check the other side.

If the two dimensions are not the same, loosen the two

screws on the fence and align it.

Retighten the two screws.

Make two or three test cuts on scrap wood. If the cuts

are not true, repeat the process.

FRAMING

SQuARE

Fig. 47

Fig. 48

StOp

pIN