RIDGID BS1400 User Manual

Page 19

19

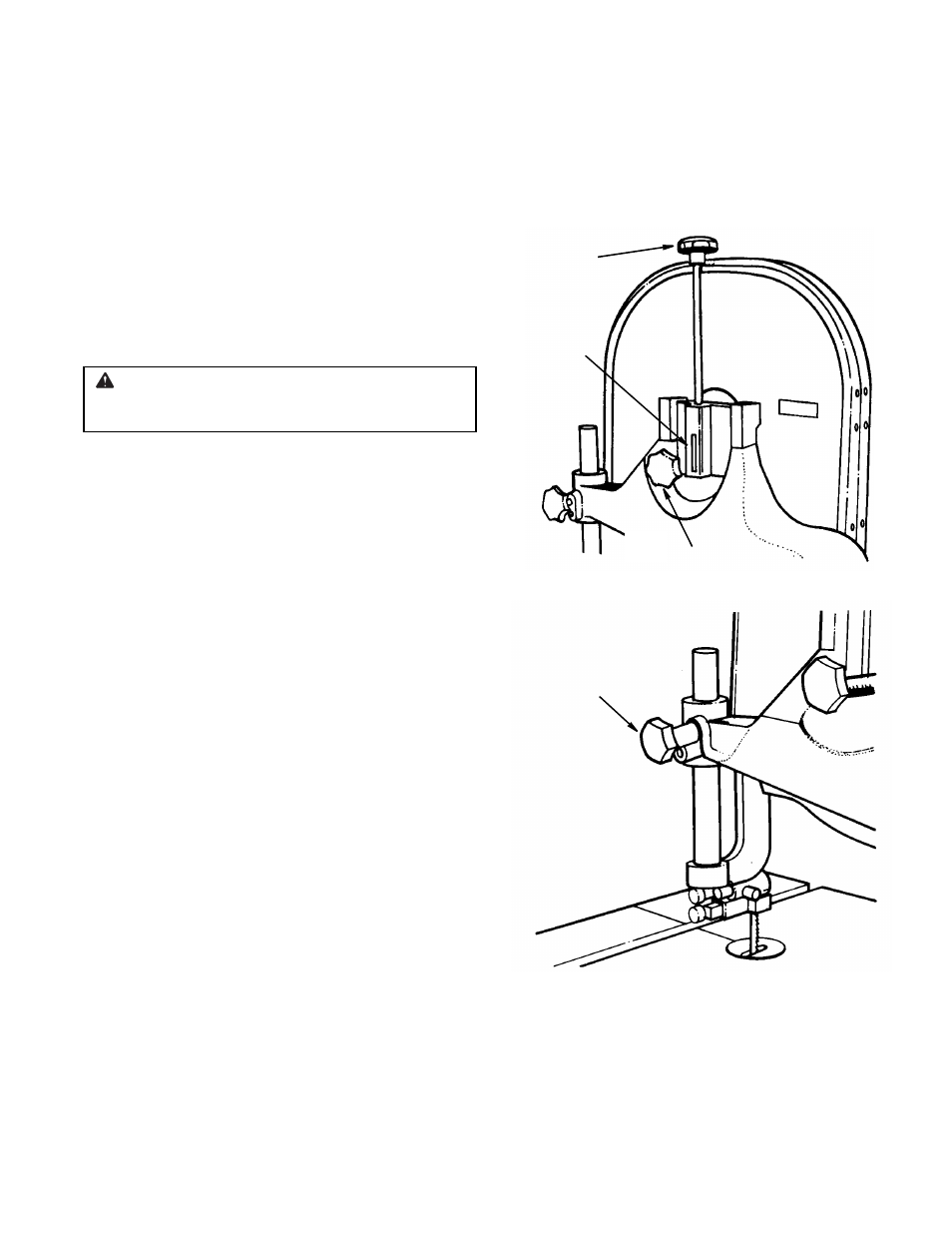

Adjusting Blade Tension

1. Disconnect machine from the power source.

2. Turn blade tension knob clockwise to tension blade. A

gauge on the upper wheel slide bracket indicates the

approximate tension according to the width of the

blade. Initially, set the blade tension gauge to corre-

spond with the blade width.

3. As you become familiar with the saw, you may find it

necessary to change the blade tension from the initial

setting. Changes in blade width and the type of mate-

rial being cut will have an effect on blade tension.

4. Keep in mind that too little or too much blade tension

can cause blade breakage.

Adjusting Blade Tracking

WARNING:

Disconnect machine from the power

source. Never adjust blade tracking with the machine

running.

1. Blade must be properly tensioned before adjusting

blade tracking. Make sure blade guides and blade

bearings do not interfere with the blade.

2. Open upper cover. Rotate the wheel forward by hand

and observe the position of the blade on the wheel. It

should be in the center.

3. If adjustment is necessary, loosen wing nut, tighten

knob slightly to move blade toward rear of machine.

Slightly loosening the knob will cause the blade to

track toward the front of the machine.

4. Tighten nut after blade is tracking in the center of the

wheel.

Adjusting Upper Blade Guide Assembly

1. Disconnect machine from the power source.

2. Loosen lock knob and raise or lower upper blade guide

assembly to just above the material being cut.

3. Tighten lock knob. Make sure blade guide blocks are

still flat to the blade. If adjustment is necessary, loosen

lock knob and rotate assembly until guide blocks are

flat to the blade.

4. The upper blade guide is spring loaded. To adjust the

tension on the spring, remove knob, tighten or loosen

set screw until desired tension is reached, and replace

knob. (See page 20)

Blade

Tension

Gauge

Blade

Tension

Knob

Blade Tracking Knob

Lock Knob