National Products BW3 User Manual

Page 6

Equipment located in buildings of unusually tight construction shall be provided with air for combustion, ventilation, and dilution of flue gases

using the methods described in example 2B or shall be specially engineered. The authority having jurisdiction must approve specially engineered

installations.

PROCEDURE 2—BOILER LOCATED IN CONFINED SPACE

EXAMPLE 2A: ALL AIR FROM INSIDE THE BUILDING

The confined space shall be provided with two permanent openings communicating directly with an additional room(s) of sufficient volume so

that the combined volume of all spaces meets the criteria for an unconfined space. The total input of all gas utilization equipment installed in the

combined space shall be considered in making this determination. Each opening shall have a minimum free area of one square inch per 1,000 Btu

per hour of the total input rating of all gas utilization equipment in the confined space, but not less than 100 square inches. One opening shall be

within 12 inches of the top and one within 12 inches of the bottom of the enclosure. The minimum dimension of air openings shall not be less

than 3 inches.

EXAMPLE 2B: ALL AIR FROM OUTDOORS

The confined space shall communicate with the outdoors in accordance with examples 1 or 2. The minimum dimension of air openings shall not

be less than 3 in. Where ducts are used, they shall be of the same cross-sectional area as the free area of the openings to which they connect.

1. Two permanent openings, one commencing within 12 inches of the top, and one commencing within 12 inches of the bottom of the

enclosure shall be provided. The openings shall communicate directly, or by the ducts, with the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors

a. Where directly communicating with the outdoors or where communicating to the outdoors through vertical ducts, each opening shall have

a minimum free area of 1 sq. in. per 4000 Btu per hour of total input rating of all equipment in the enclosure. (See Table 3A.)

b. Where communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1 sq. in. per 2000

Btu per hour of total input rating of all equipment in the enclosure. (See Table 3B.)

2. One permanent opening commencing with 12 inches of the top of the enclosure shall be permitted where the equipment has clearance of

at least 1 inch from the sides and back and 6 inches from the front of the appliance. The opening shall directly communicate with the

outdoors or shall communicate through a vertical or horizontal duct to the outdoors or spaces (crawl or attic) that freely communicate with

the outdoors and shall have a minimum free area of:

a. 1 sq. inch per 3000 Btu per hour of the total input of all equipment located in the enclosure (see Table 3C), and

b. Not less than the sum of the areas of all vent connectors in the confined space.

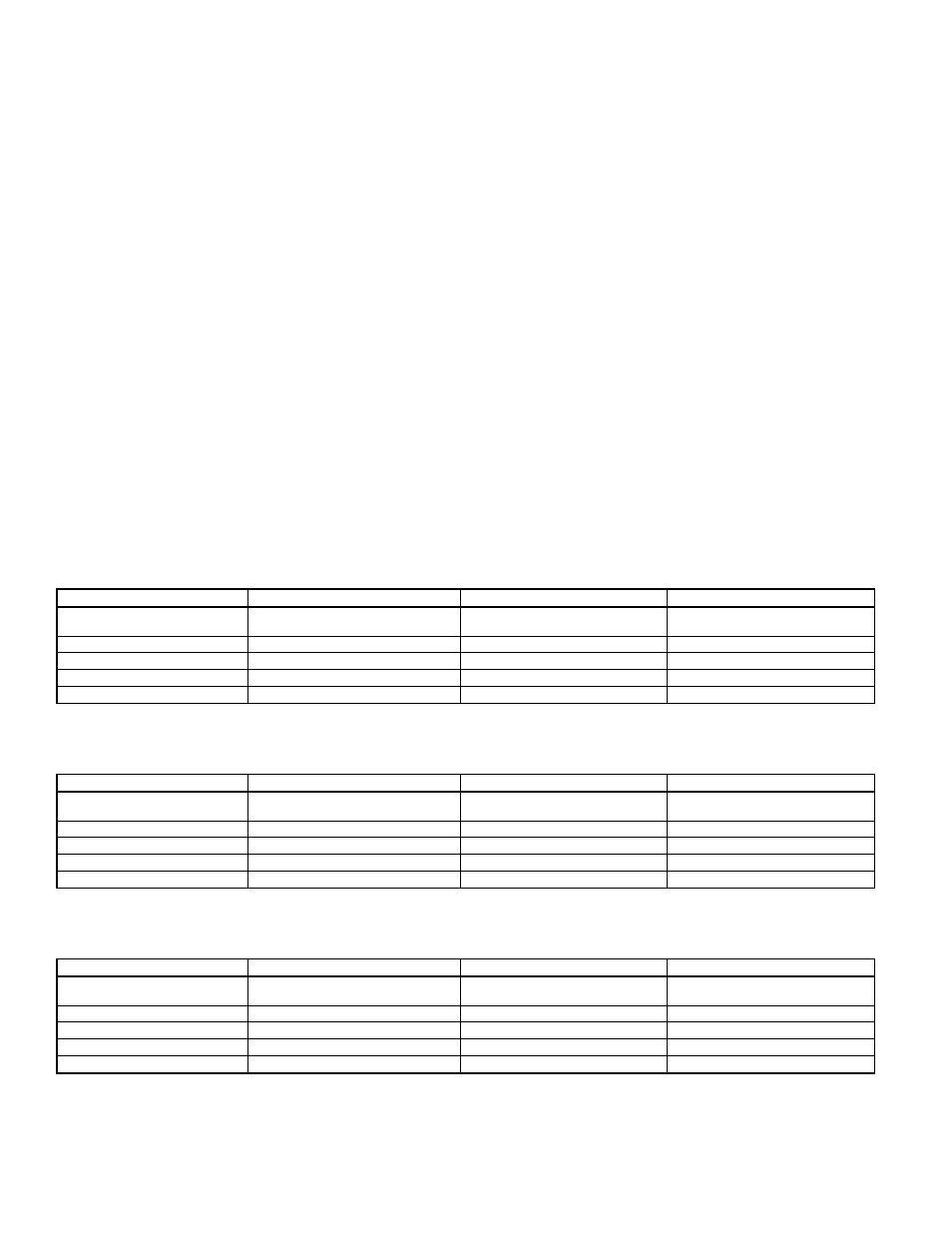

Table 3A—Fresh Air Duct Capacities for Vertical Ducts (Btuh)*

100% FREE AREA

75% FREE AREA

25% FREE AREA

Fresh Air

Duct Size (In.)

1/4-in. Mesh

Screen

Metal

Louvers

Wood

Louvers

3" X 12"

144,000

108,000

36,000

8" X 8"

256,000

192,000

64,000

8" X 12"

384,000

288,000

96,000

8-1/2" X 16"

512,000

384,000

128,000

* 1 Square Inch per 4,000 Btuh

Table 3B—Fresh Air Duct Capacities for Horizontal Ducts (Btuh)*

100% FREE AREA

75% FREE AREA

25% FREE AREA

Fresh Air

Duct Size (In.)

1/4-in. Mesh

Screen

Metal

Louvers

Wood

Louvers

3" X 12"

72,000

54,000

18,000

8" X 8"

128,000

96,000

32,000

8" X 12"

192,000

144,000

48,000

8-1/2" X 16"

256,000

192,000

64,000

* 1 Square Inch per 2,000 Btuh

Table 3C—Fresh Air Duct Capacities for Vertical or Horizontal Ducts (Btuh)*

100% FREE AREA

75% FREE AREA

25% FREE AREA

Fresh Air

Duct Size (In.)

1/4-in. Mesh

Screen

Metal

Louvers

Wood

Louvers

3" X 12"

108,000

81,000

27,000

8" X 8"

192,000

144,000

48,000

8" X 12"

288,000

216,000

72,000

8-1/2" X 16"

384,000

288,000

96,000

* 1 Square Inch per 3,000 Btuh

—6—