Ventilation requirement, Ventilation requirements, Certified vent kits – Thetford Norcold 453 User Manual

Page 5

VENTILATION REQUIREMENTS

WARNING: Carbon Monoxide can cause

nausea, fainting, or death. Inadequate ven-

tilation or partial blockage of the refrigera-

tor’s flue can result in increased carbon

monoxide emissions when operating in the

gas mode. To prevent the emission of lev-

els of carbon monoxide, installation must

assure complete isolation of the living

space of the R.V. from the refrigerator’s

combustion system. Follow Norcold’s Ven-

tilation and Installation recommendations

explicity.

Venting is required in an R.V. refrigerator installa-

tion to remove the products of combustion, to isolate

the living space of the vehicle from the combustion

system of the refrigerator, to remove the excess heat

from the generator area of the refrigerator’s cooling

system, and to remove the heat that is extracted

from the refrigerator cabinet.

Certified installation requires that one intake (lower)

and one exhaust (upper) be used. For the models

6052, 6053, 652, and 653, the installer has the op-

tion of exhausting through the roof or through an up-

per side wall vent. Whether roof or side wall exhaust

venting, the specified vent kit must be installed as

directed by this manual. To insure adequate refrig-

erator performance, a continuous air flow is required

across the refrigerator’s cooling system.

The air passage from the intake vent to the refrigera-

tor coils and from the refrigerator coils through the

exhaust vent must be unobstructed.

TABLE 1

DIMENSIONS (INCHES) for Vent Kits 2, 3, and 4

The vents for these refrigerators are certified by

A.G.A. and CGA and must be installed as directed

by this manual without modification. Any deviation

or substitution:

* Can result in carbon monoxide levels in the living

space of the vehicle.

* Will void the agencies’ certification.

* Will void the refrigerator warranty.

* Will effect refrigerator performance.

The intake vent (lower) also serves as a access

(service entrance) door. The bottom of the intake

vent opening must be flush with the surface on which

the refrigerator is mounted. This configuration allows

any leaking propane to ventilate to the outside.

A.G.A. And CGA certification permits installing the

refrigerator with zero (0) inches minimum clearance

between the refrigerator and any adjacent walls. This

certification does not specify any maximum clear-

ance. However, to insure adequate air flow across

the cooling system, the clearance must be mini-

mized. The combination of the two vents and the

minimum clearances provide the necessary air flow

through the creation of a natural draft, or "chimney

effect" across the cooling system.

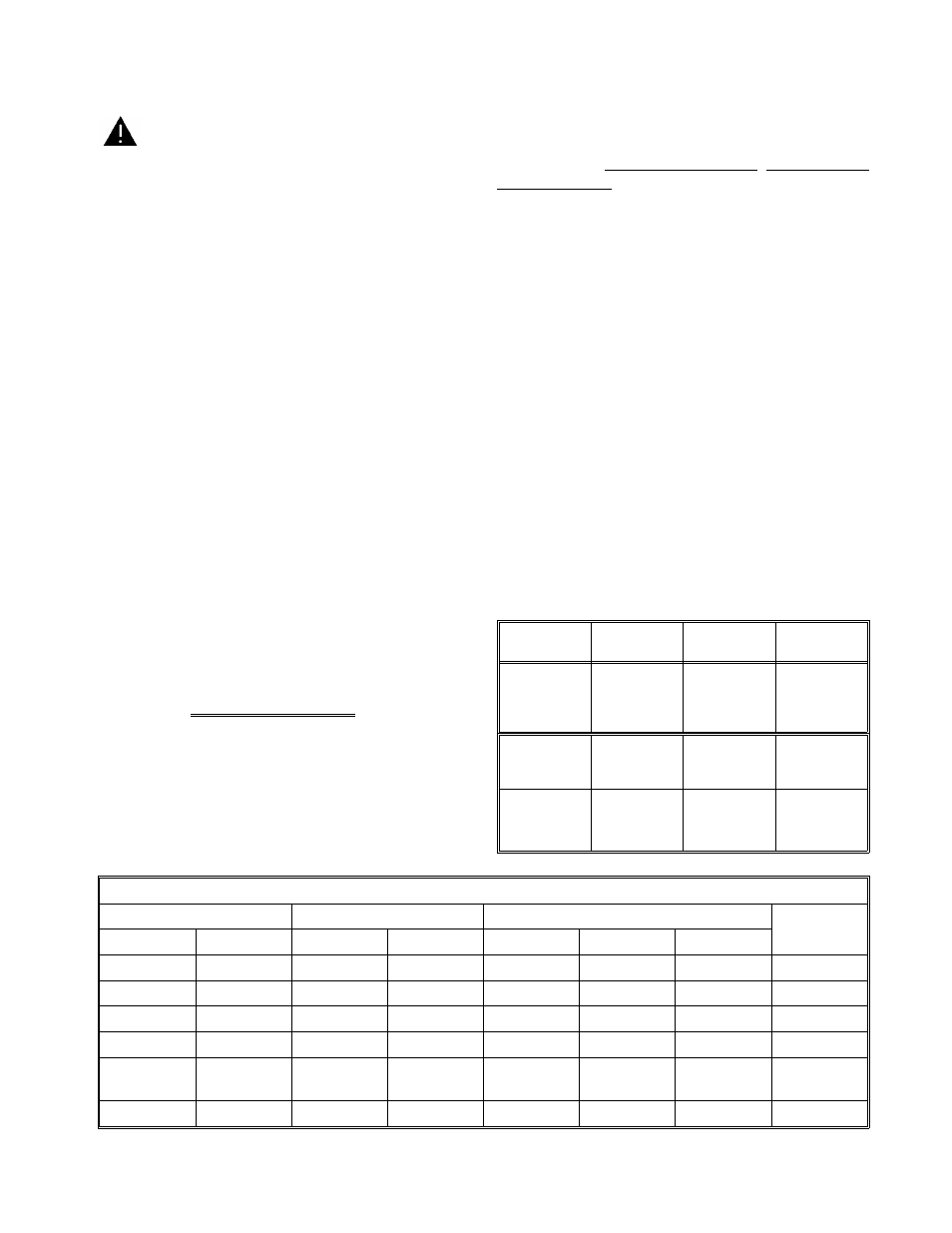

Certified Vent Kits

Kit Number

Certified Lower

Vent Door

Certified

Roof Jack

Models

2 & 3

615998

616009

616010

617778

615791

All Models

Kit Number

Certified Lower

Vent Door

Certified

Upper Side

Exhaust

Models

4

615998

616009

616010

617778

617485

442. 443

452, 453

ONLY

Cut - Out Dimension (inches)

Roof Jack

Lower Intake Vent

Approved

Models

Part No.

Type

Length

Width

Height

Width

Radius

617778

Plastic

- -

- -

13 3/4

21 1/2

- -

All Models

616010

Sq. Corner

- -

- -

13 3/4

21 3/4

- -

All Models

616009

Rad. corner

- -

- -

13 3/4

21 7/8

3 1/4

All Models

615998

Rad. Corner

- -

- -

13 3/4

21 7/8

3 1/4

All Models

85

Upper Side

vent

--

--

7 1/4

18

--

6052, 6053

652, 653

615791

Roof Jack

24

5 1/4

- -

- -

- -

All Models

5