Thetford Norcold 453 User Manual

Page 10

supply connects to the terminal block at the rear of

the refrigerator (See Figure 9 on page 8). The 12 volt

DC should enter the refrigerator’s enclosure near the

refrigerator’s terminal block. The 12 volt DC connects

at (2) one quarter inch quick connects. The positive

DC input lead connects to terminal marked (+), and

the DC ground input lead connects to terminal

marked (-).

CAUTION: Correct polarity must be ob-

served when connecting the DC supply.

Do not use the chassis of the refrigerator

or the vehicle frame as one of the conduc-

tors. Connect DC supply wires at the bat-

tery and route to the refrigerator.

The distance the current travels from the battery to

the refrigerator dictates the wire size. Undersized

wire can result in a voltage drop, which will affect the

wattage output of the DC heater and result in re-

duced refrigerator performance. Norcold recommends

the installation of a fuse in the supply wiring between

the battery and the refrigerator. For optimum protec-

tion, install the fuse as close to the battery as possi-

ble.

WARNING: A circuit overload can result in

an electrical fire when undersized wires or

improperly sized fuses are used. To pre-

vent a possible electrical fire, follow

R.V.I.A. A119.2 Standards, Norcold’s wire

size and fuse specifications, or applicable

state and local codes.

TABLE 3

12 VOLT SUPPLY WIRING AND FUSE SIZE

482, 462

452, 442

483, 463

453, 443

min.

wire

size

max.

fuse

size

min.

wire

size

max.

fuse

size

Min.

wire

size

max.

fuse

size

0 - 20’

18

AWG

6 Amp

10

AWG

30

Amp

12

AWG

20

Amp

over

20’

18

AWG

6 Amp

8

AWG

40

Amp

10

AWG

30

Amp

If a wire size is installed which is larger than the

minimum size indicated the table above, it must be

fused in accordance with the R.V.I.A. A119.2 stand-

ard or local governing codes.

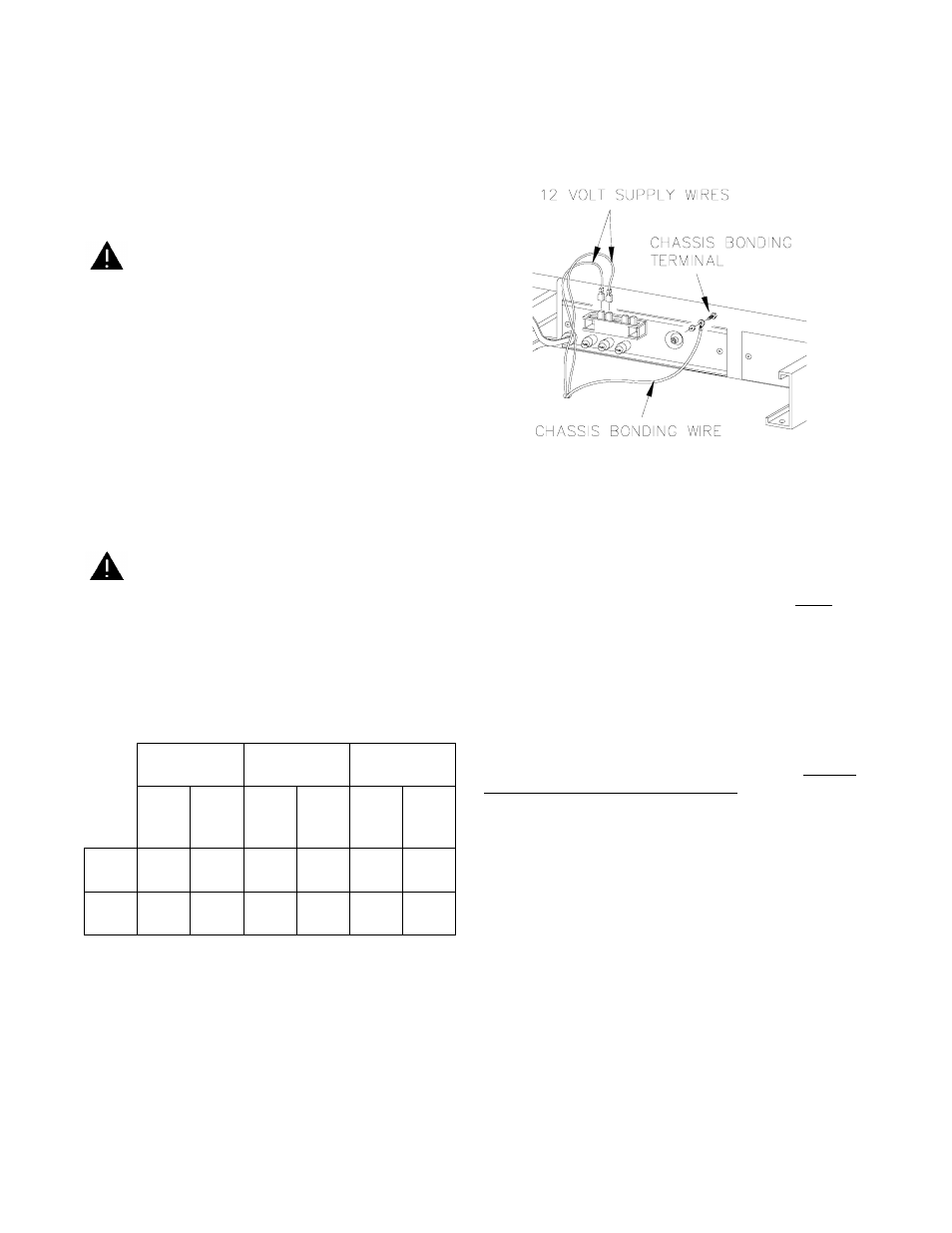

Chassis Bonding Connection

A No. 8 AWG copper conductor is commonly used

to meet the chassis bonding requirements of the Na-

tional Electric Code (ANSI/NFPA No. 70, Art. 551).

When this conductor is used to bond the non-current

carrying metal parts of the refrigerator, a No. 10-32

bonding terminal is provided to make the connection.

(See Figure 10 ).

Hypot Test

A Dielectric Strength test (hypot) has been con-

ducted at the factory; this refrigerator does not re-

quire an additional test. If hypot tests are conducted

on the vehicle’s 12 volt circuit, the 12 volts must be

disconnected from the refrigerator to protect the

flame ignition circuit.

Testing the Vehicle’s Gas Supply Piping

When installation of the refrigerator is complete, the

propane gas supply piping must be inspected and

tested for leaks from the refrigerator to the main gas

supply tank. Use a leak detection solution. Do not

test for leaks with an open flame.

If compressed air is used for leak testing, the gauge

pressure must not exceed 1/2 pound per square inch

(14 inches water column).

The appliance and its individual shut-off valve (Fig-

ure 11 on page 10) must be disconnected from the

gas supply system during any pressure testing of that

system at test pressures greater than 1/2 psig (14

inches water column).

The appliance must be isolated from the gas supply

system by closing its individual manual shut-off valve

(Figure 11 on page 10) during any pressure testing

of that system at test pressure equal to or less than

1/2 psig (14 inches water column).

Check the gas pressure to the refrigerator without

other gas appliances operating. The pressure should

not exceed 11 inches water column. With other appli-

ances operating the pressure should not be less than

10.5 inches water column.

Figure 10

10