Operating advantages – Nortec GS Series User Manual

Page 3

Economy

NORTEC GS Series Gas Steam humidifiers

provide clean steam humidification at an

economical operating cost. Units are packaged

in a powder coated cabinet for zero clearance

space requirement while offering high efficiency

output. They can be controlled from either a local

humidistat, from the central building management

system or multiple units can be staged together.

The combustion system utilizes a modulating

forced draft combustion air blower, a negative

pressure regulator gas valve and a 100% premix

burner. On a call for humidity, the combustion

air blower starts creating a negative pressure

across the valve orifice located at the air inlet.

The hot surface ignitor then energizes. The gas

valve opens and the regulated gas/air mixture is

forced through the burner ports and is ignited.

Easy Maintenance

The compact stainless steel heat exchanger has

large flat surfaces to minimize scale buildup

in the humidifier tank. Scale tends to fall off

the exchanger wall to the bottom of the tank,

maintaining efficient heat transfer to the water and

extending the intervals between cleanings. The

smooth stainless steel surface of the tank and

removeable heat exchanger are easily cleaned and

maintained.

The GS SERIES compact heat exchanger design

provides a minimum footprint area where space

requirement is an issue.

operating advantages

Compact removeable heat exchanger.

105 lbs/hr of clean steam.

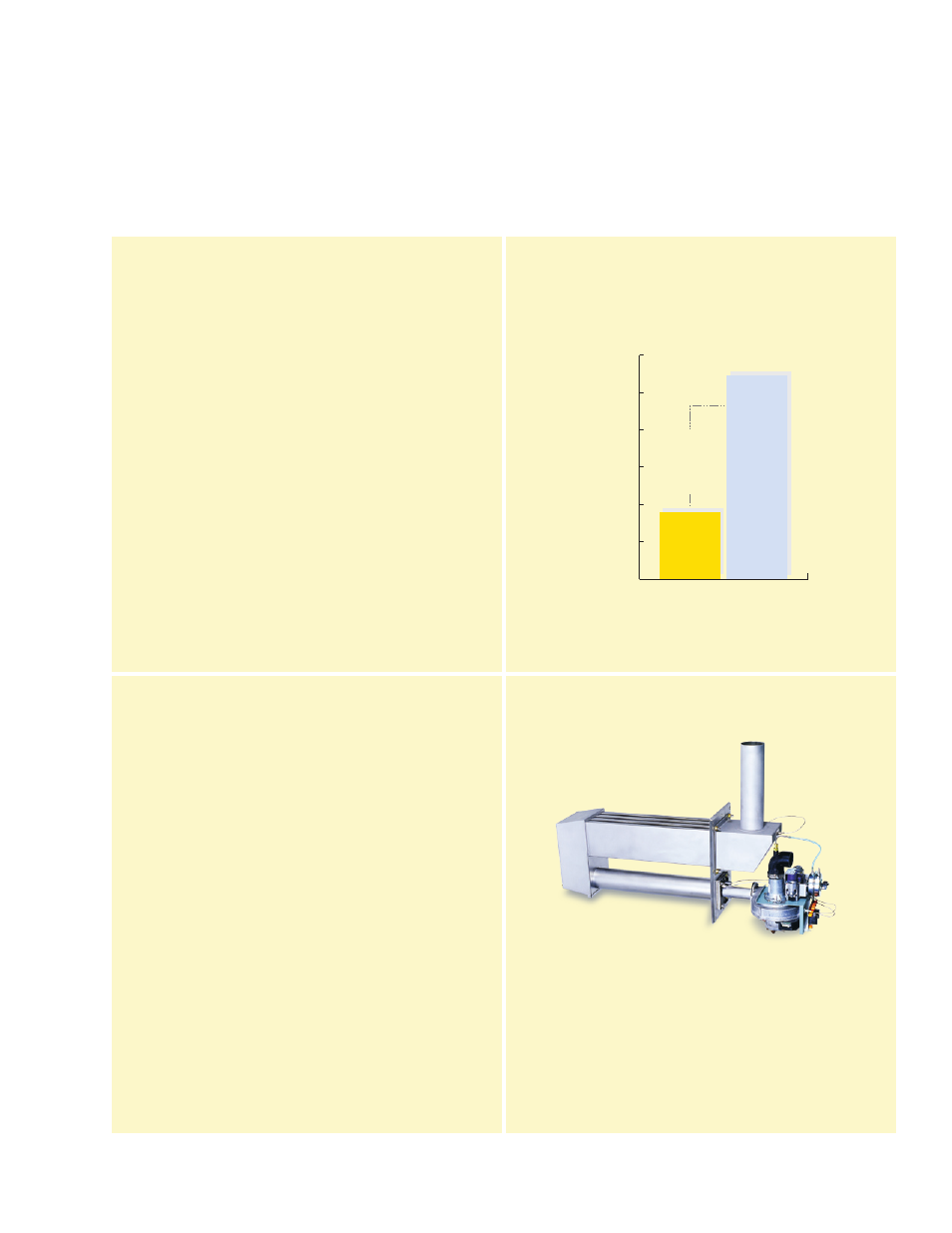

$/year

Operating costs based an electric cost of $0.08 per kWh, natural gas cost

$0.75 per therm, full output for 2,000 hours per season. Efficiency of

electric unit is 97% and efficiency of gas unit is 82%. Costs do not include

electric peak demand charges.

Annual

savings

with gas

$

3,658

0

1000

2000

3000

4000

5000

6000

Electric

$

5,443

Gas

$

1,784

Annual Operating Cost of

Natural Gas Humidifier vs Electric Humidifier

100 lbs/hr (45 kg/hr)